Method for evaluating development capability

A capability and developing machine technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as cost increase, photoresist residue, affecting the quality of semiconductor devices, etc., to achieve the effect of cost reduction and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

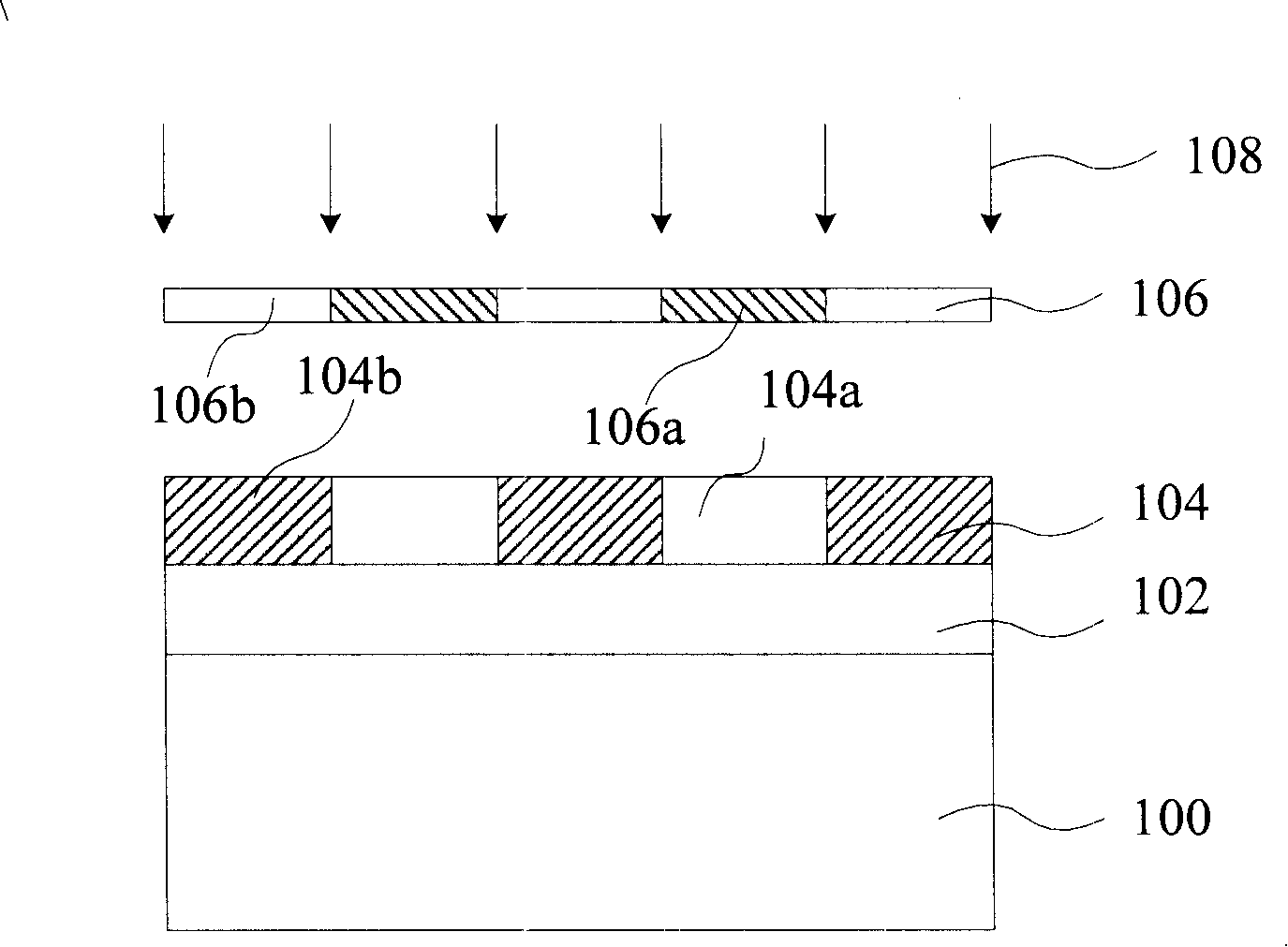

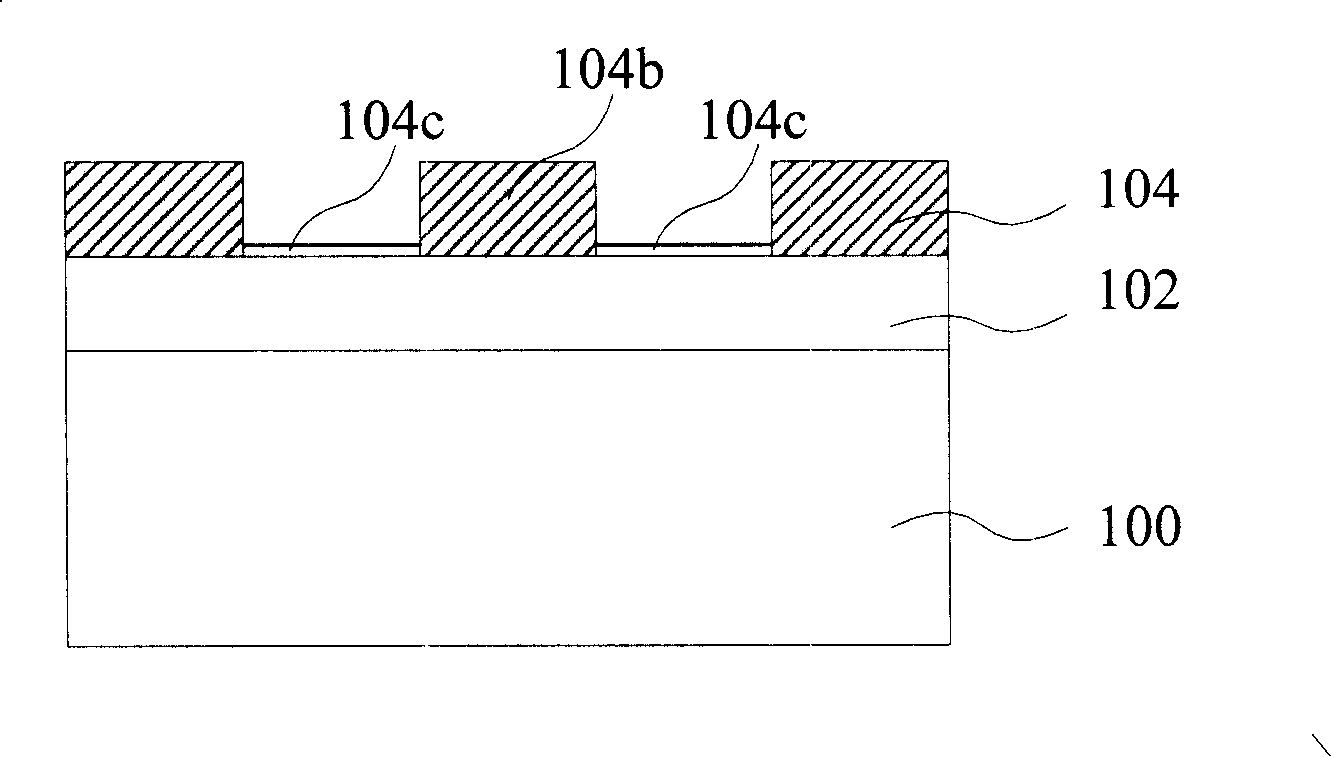

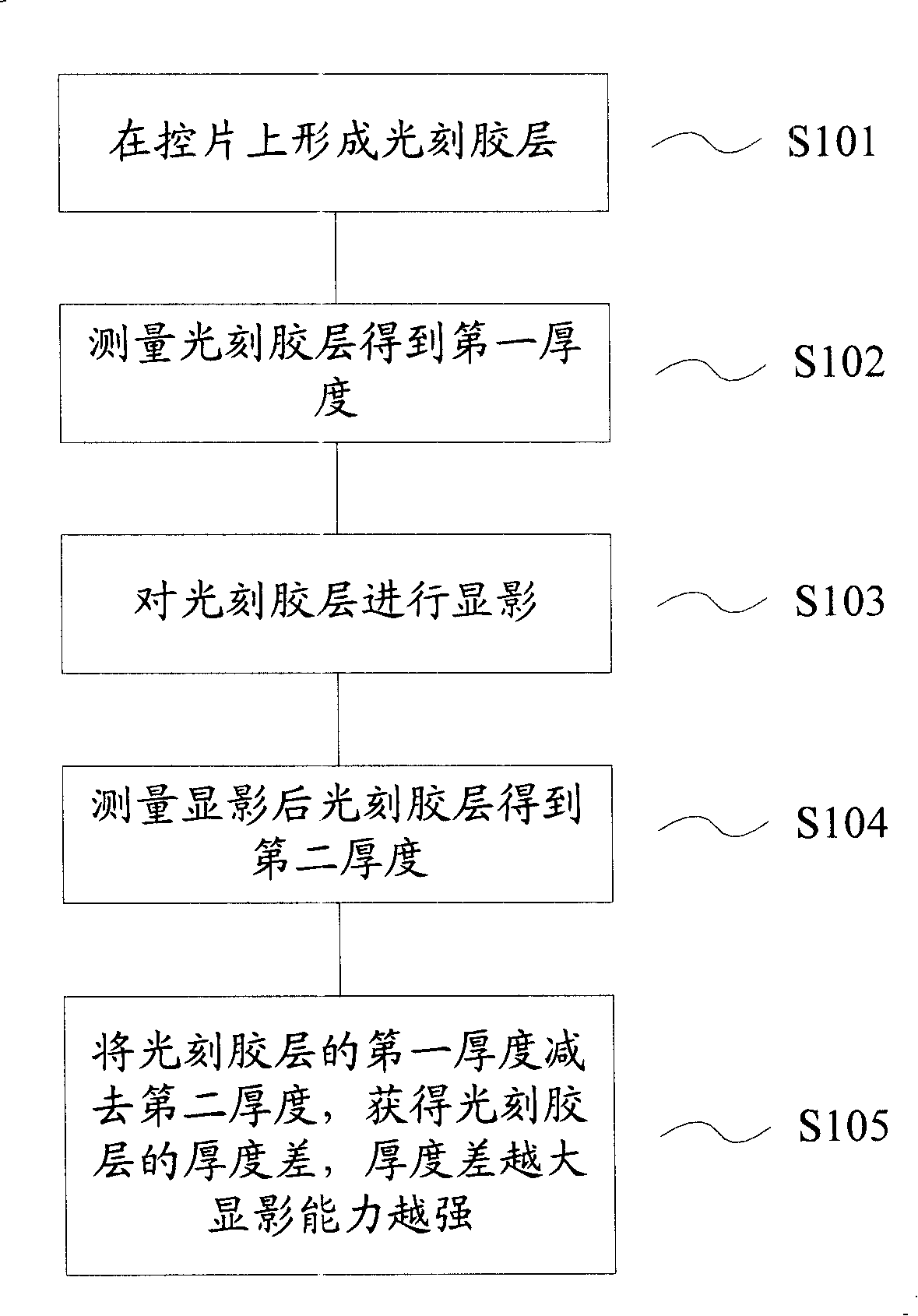

[0020] In the existing photolithography process, photoresist residues are usually caused by insufficient development, which in turn affects the quality of subsequent semiconductor devices; usually photoresist residues are caused by insufficient development, which in turn affects the quality of subsequent semiconductor devices; Evaluate the developing ability of the developing machine—the effect of developing photoresist. Generally, after the formed semiconductor device is sliced, it is made into a scanning electron microscope sample to observe whether the photoresist remains, which will increase the cost and affect the quality of the semiconductor device. Yield. The present invention forms a photoresist layer on the control sheet, measures the first thickness of the photoresist layer before development, measures the second thickness of the photoresist layer after development, and subtracts the second thickness from the first thickness to obtain Find the developing ability of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com