Solid solution aging technique for modifying Cu-Ag alloy rigidity and electric conductivity

A technology of solution aging and electrical conductivity, applied in the field of heat treatment of copper-based alloys, to achieve the effect of easy implementation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The metal Ag and electrolytic Cu are mixed according to the mass percentage, among which the metal Ag is 5%, and the rest is electrolytic Cu. First, Cu is placed in a vacuum induction furnace, melted at an atmospheric pressure lower than 0.1Pa, and degassed at 1150°C. Then fill the furnace with Ar to 450kPa, then add Ag and melt it, electromagnetically stir it evenly and let it stand for 2-3 minutes, then cast it into a plate-shaped ingot of 16×42×170mm.

[0025] The ingot is solid solution treated by isothermal water cooling at 730°C / 8h+760°C / 4h.

[0026] The solution-treated ingots were aged at 350°C for 2 hours and subjected to isothermal air-cooling treatment.

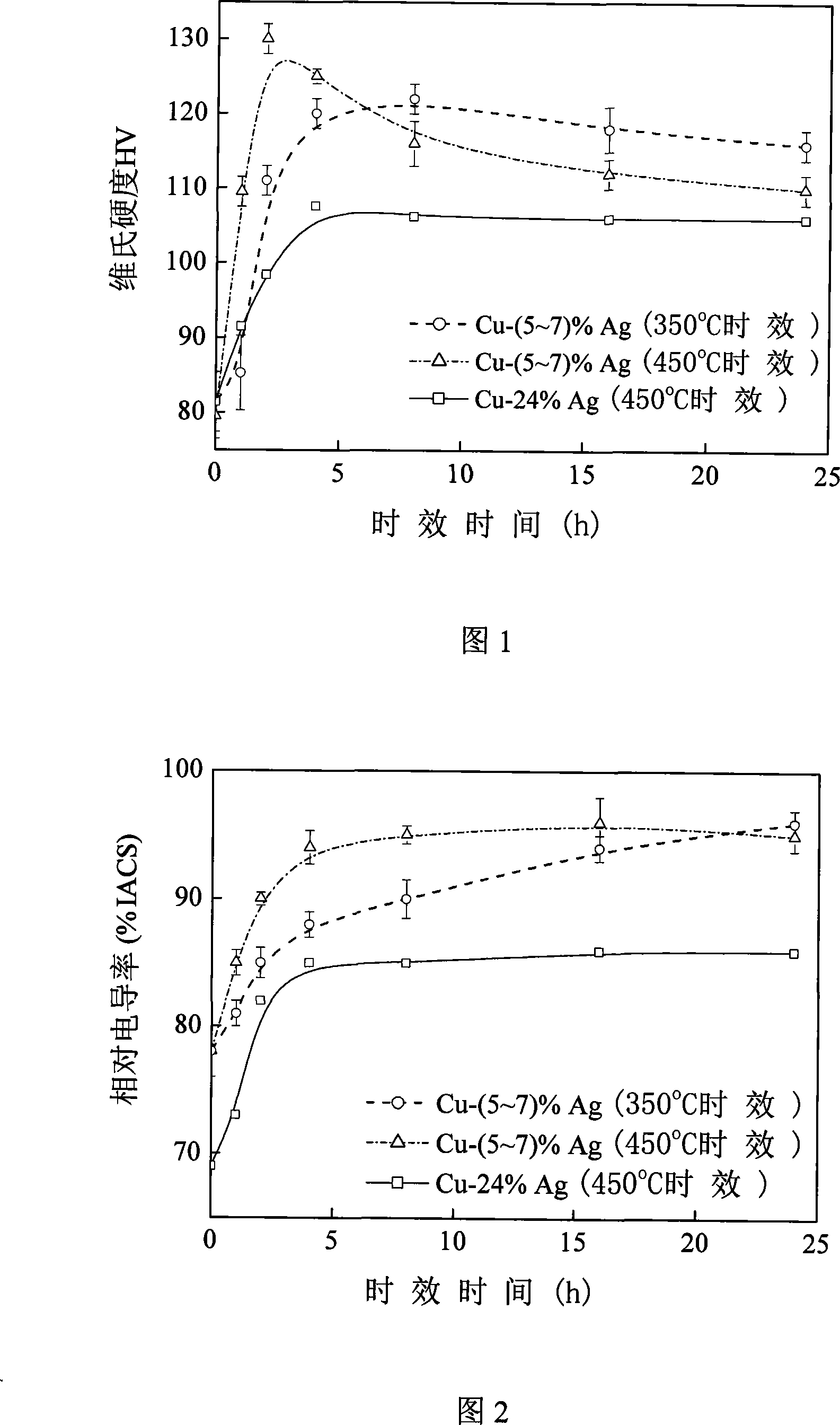

[0027] After the above processing and heat treatment, the Vickers hardness reaches 111, and the relative conductivity reaches 85% IACS change (see Figure 1 and Figure 2).

Embodiment 2

[0029] Metal Ag and electrolytic Cu are mixed according to mass percentage, wherein the metal Ag is 6%, and the rest is electrolytic Cu. The ingot smelting and casting process are the same as in Example 1.

[0030] The ingot is solution treated by isothermal water cooling at 730°C / 8h+760°C / 8h.

[0031] The solution-treated ingots were aged at 350°C for 24 hours and subjected to isothermal air-cooling treatment.

[0032] After the above processing and heat treatment, the Vickers hardness reaches 116, and the relative electrical conductivity reaches 96% IACS (see Figure 1 and Figure 2).

Embodiment 3

[0034] Metal Ag and electrolytic Cu are mixed according to mass percentage, wherein the metal Ag is 6.5%, and the rest is electrolytic Cu. The ingot smelting and casting process are the same as in Example 1.

[0035] The ingot is solid solution treated by isothermal water cooling at 730°C / 8h+780°C / 4h.

[0036] The solution-treated ingots were aged at 450°C for 2 hours and subjected to isothermal air-cooling treatment.

[0037] After the above processing and heat treatment, the Vickers hardness reaches 130, and the relative electrical conductivity reaches 90% (see Figure 1 and Figure 2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com