Island type polyamide 6 fibre and preparing method thereof

A polyamide, island-in-the-sea technology, used in fiber processing, filament/thread forming, conjugated synthetic polymer rayon, etc., can solve problems such as light resistance, poor heat resistance, gray fabric color, and aggravating environmental pollution. , to achieve the effect of overcoming gray color, bright color and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

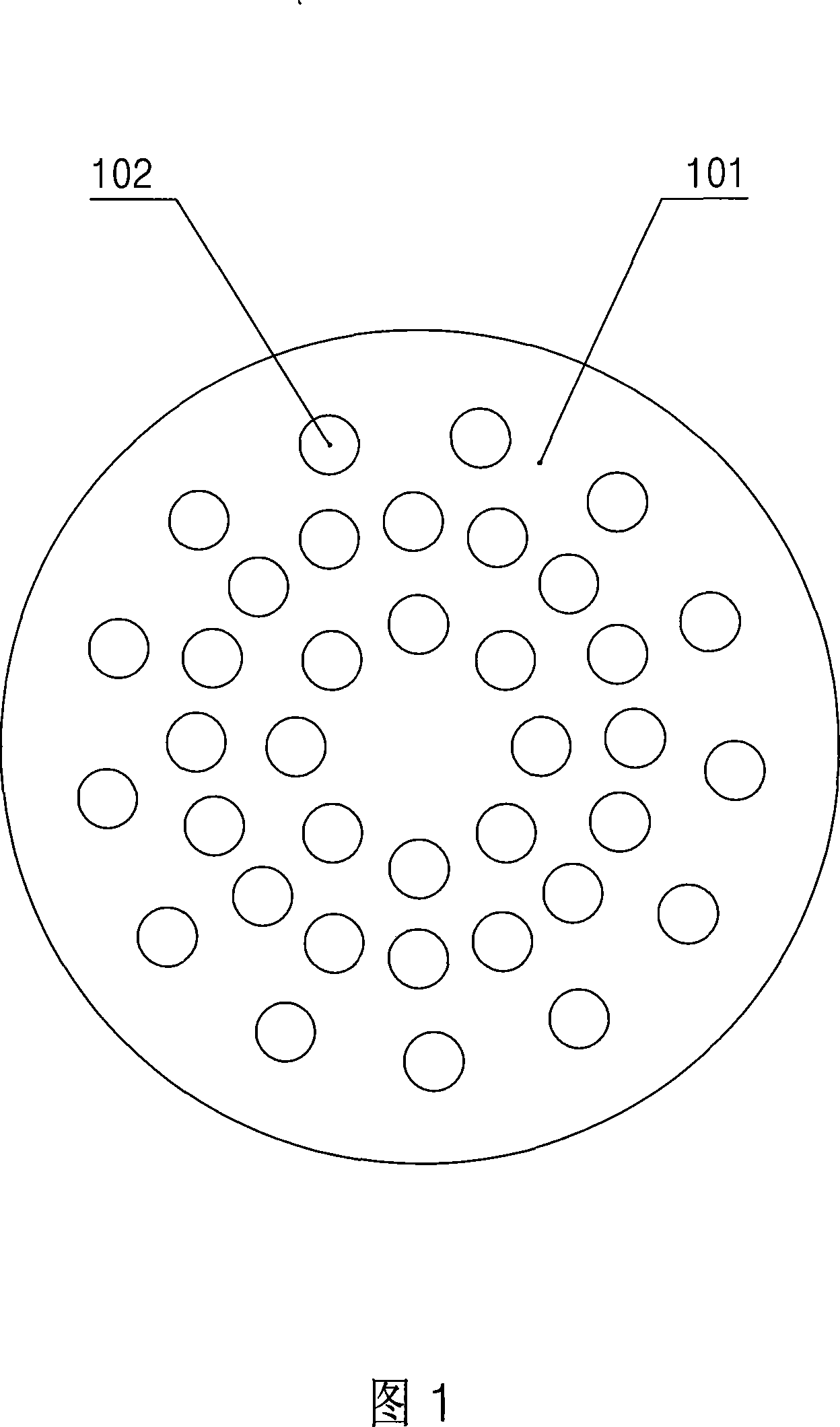

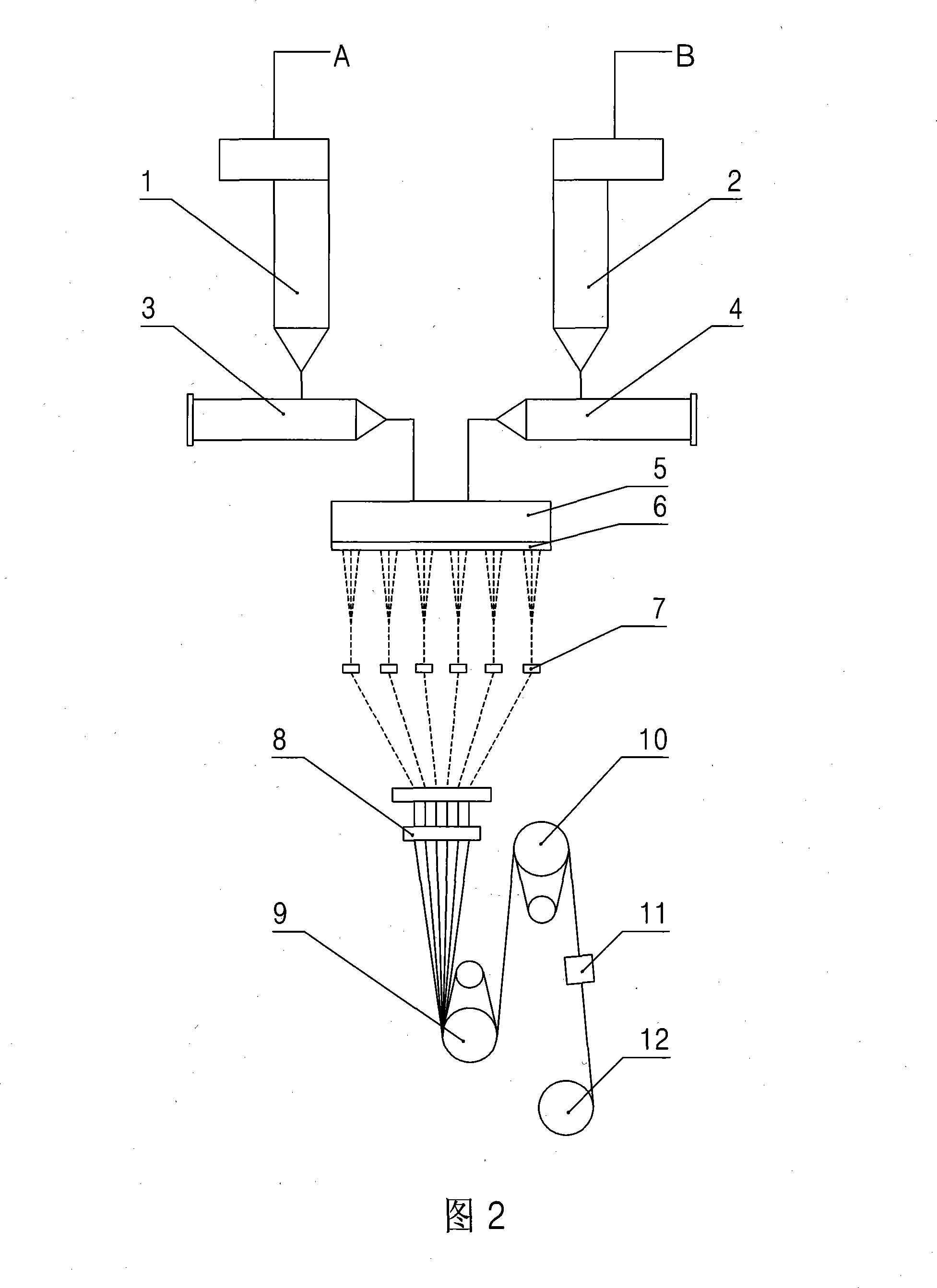

[0016] As shown in Figure 2, 40 parts (weight) of fiber-grade nylon 6 (polyamide 6) slices are sent into the warehouse 1 protected by low-temperature dry air as the first raw material A, so that the moisture content of nylon 6 < 200PPM, and then sent into the first screw extruder 3, and melted and extruded by the first screw extruder 3 to become a spinnable polyamide 6 melt. The melt extrusion process of the first screw extruder 3 is provided with 3 to 5 sections In the heating zone, the heating temperature of each zone is set between 250°C and 280°C (such as 250°C, 260°C, 270°C), and then the polyamide 6 melt is sent to the spinning box 5, and further evenly distributed to the island In the type composite spinning component, it is used as the sea component of the sea-island type polyamide 6 fiber;

[0017] At the same time, send 60 parts (weight) of fiber-grade polyester chips into the drying tower 2 as the second raw material B for drying, and then make fiber-grade polyester...

Embodiment 2

[0020] As shown in Figure 2, 60 parts (weight) of fiber-grade nylon 6 (polyamide 6) slices are sent into the warehouse 1 protected by low-temperature dry air as the first raw material A, so that the moisture content of nylon 6 < 200PPM, and then sent into the first screw extruder 3, and melted and extruded by the first screw extruder 3 to become a spinnable polyamide 6 melt. The melt extrusion process of the first screw extruder 3 is provided with 3 to 5 sections In the heating zone, the heating temperature of each zone is set between 250°C and 280°C (such as 250°C, 260°C, 270°C), and then the polyamide 6 melt is sent to the spinning box 5, and further evenly distributed to the island In the type composite spinning component, it is used as the sea component of the sea-island type polyamide 6 fiber;

[0021] At the same time, send 40 parts (weight) of fiber-grade polyester chips into the drying tower 2 as the second raw material B for drying, then make fiber-grade polyester dry...

Embodiment 3

[0024] As shown in Figure 2, 80 parts (weight) of fiber-grade nylon 6 (polyamide 6) chips are sent into the silo 1 protected by low-temperature dry air as the first raw material A, so that the moisture content of nylon 6 < 200PPM, and then sent into the first screw extruder 3, and melted and extruded by the first screw extruder 3 to become a spinnable polyamide 6 melt. The melt extrusion process of the first screw extruder 3 is provided with 3 to 5 sections In the heating zone, the heating temperature of each zone is set between 250°C and 280°C (such as 250°C, 260°C, 270°C), and then the polyamide 6 melt is sent to the spinning box 5, and further evenly distributed to the island In the type composite spinning component, it is used as the sea component of the sea-island type polyamide 6 fiber;

[0025] At the same time, send 20 parts (weight) of fiber-grade polyester chips into the drying tower 2 as the second raw material B for drying, then make fiber-grade polyester dry chips...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com