Pneumatic valve

An air-controlled valve and valve body technology, applied in sliding valves, valve details, valve devices, etc., can solve the problems of easy failure, high labor intensity and high cost, and achieve the goal of improving response speed, reducing labor intensity and improving service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

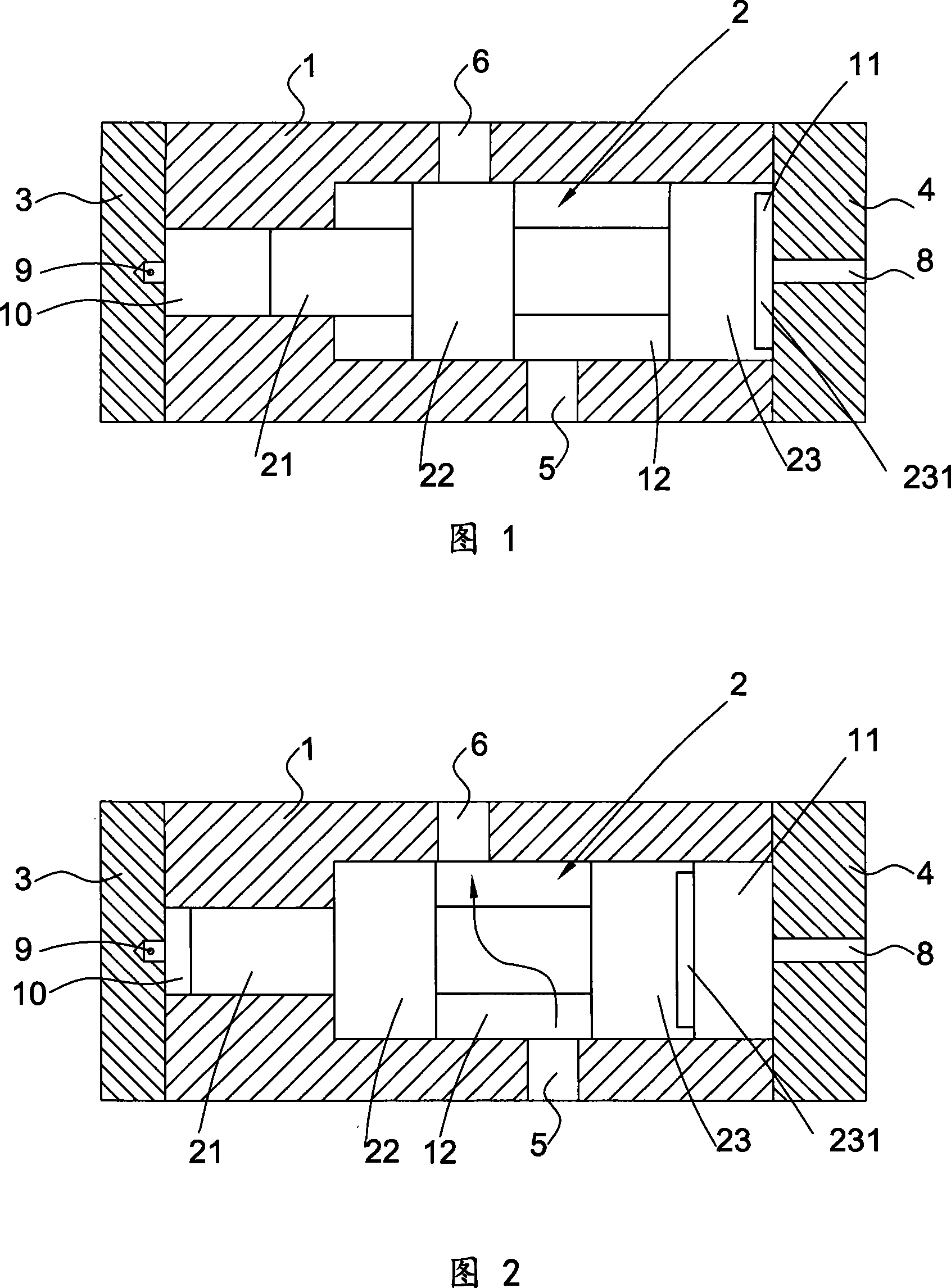

[0021] The content of the invention will be described in detail below in conjunction with the accompanying drawings.

[0022] As shown in Figure 1, an air-operated valve includes a valve body 1, a valve core 2 slidably arranged in the inner cavity of the valve body 1, and two valve cores that are respectively sealed and fitted on the valve body 1. The front end cover 3 and the rear end cover 4 of end (the left side among the accompanying drawings 1 is the "front" side described in the description, and the right side among the accompanying drawings 1 is the "rear" side described in the description). In order to better improve the reaction speed of the valve core 2 and reduce the friction between the valve core 2 and the valve body 1, a very small metal gap is used between the valve core 2 and the valve body 1 to seal and cooperate, and the valve core 2 and the valve body 1 Adding some lubricating oil between them can make the valve core 2 move more smoothly and the sealing effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com