Grid pressure sensing chip and preparation method, pressure distributed sensor

A distributed sensor and sensor chip technology, applied in the measurement of the property force of piezoelectric resistance materials, fluid pressure measurement by changing ohmic resistance, instruments, etc., can solve the problem that pressure sensors cannot detect pressure distribution and are inconvenient to operate. , large size and other problems, to achieve the effect of light weight, simple and convenient operation, small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

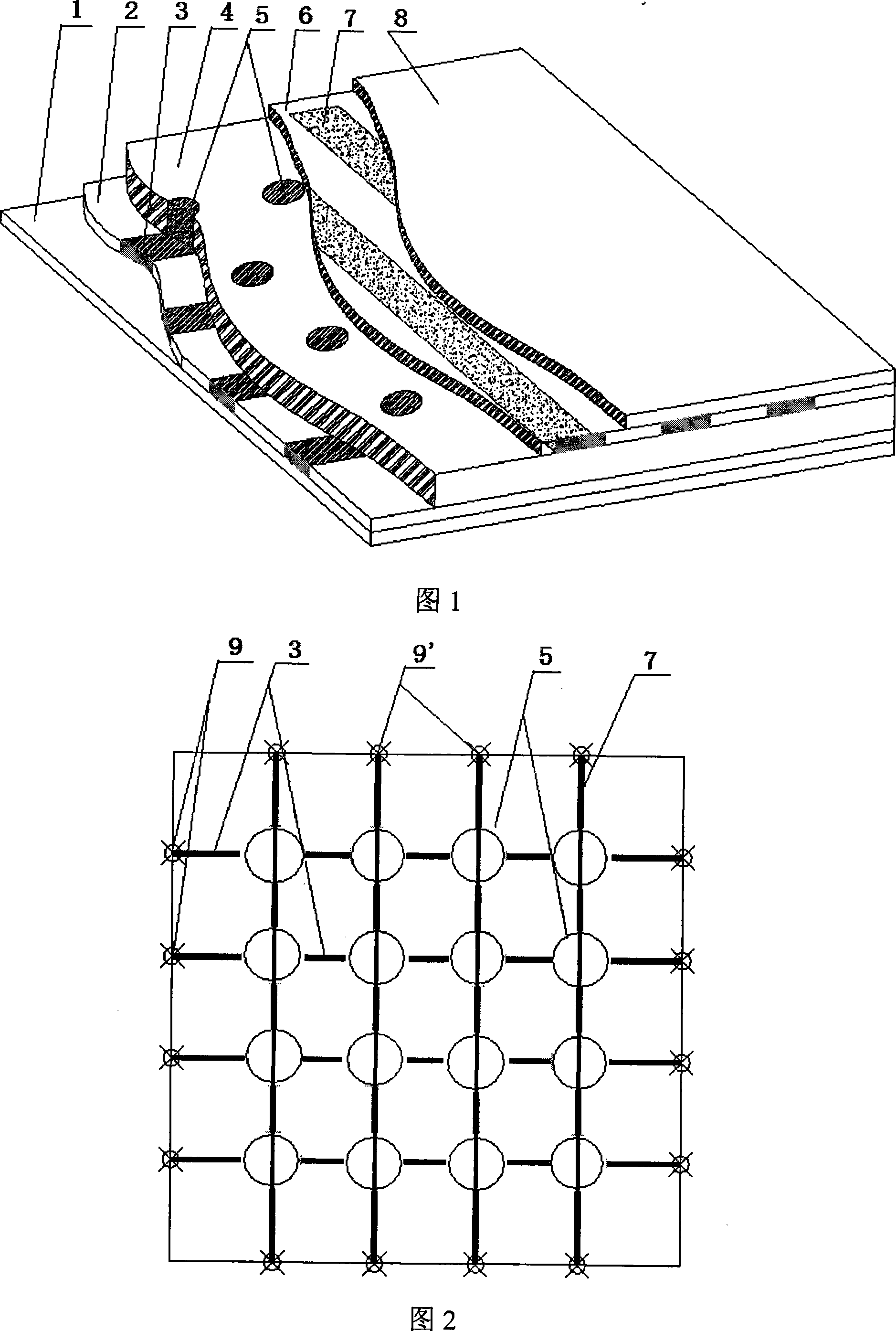

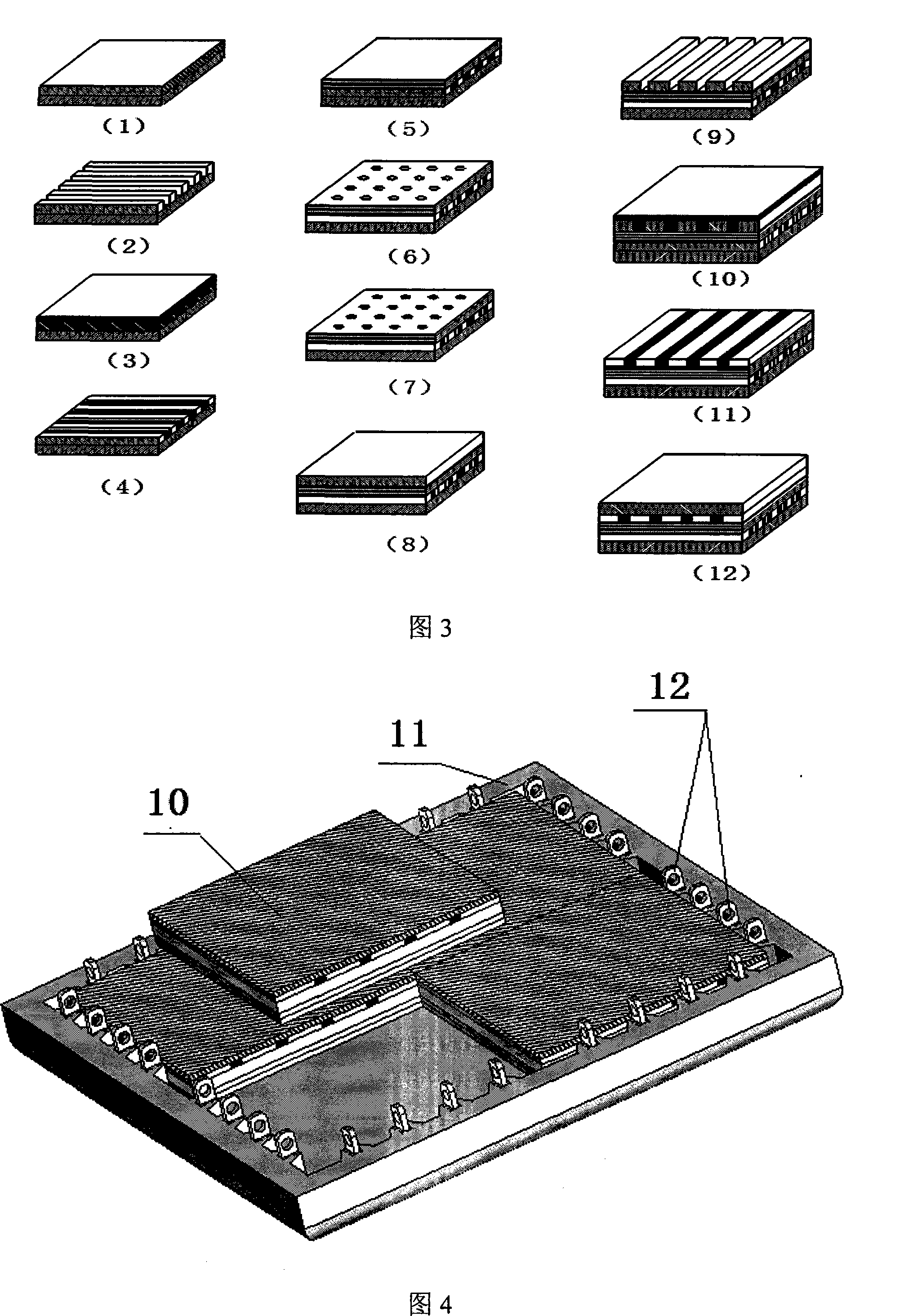

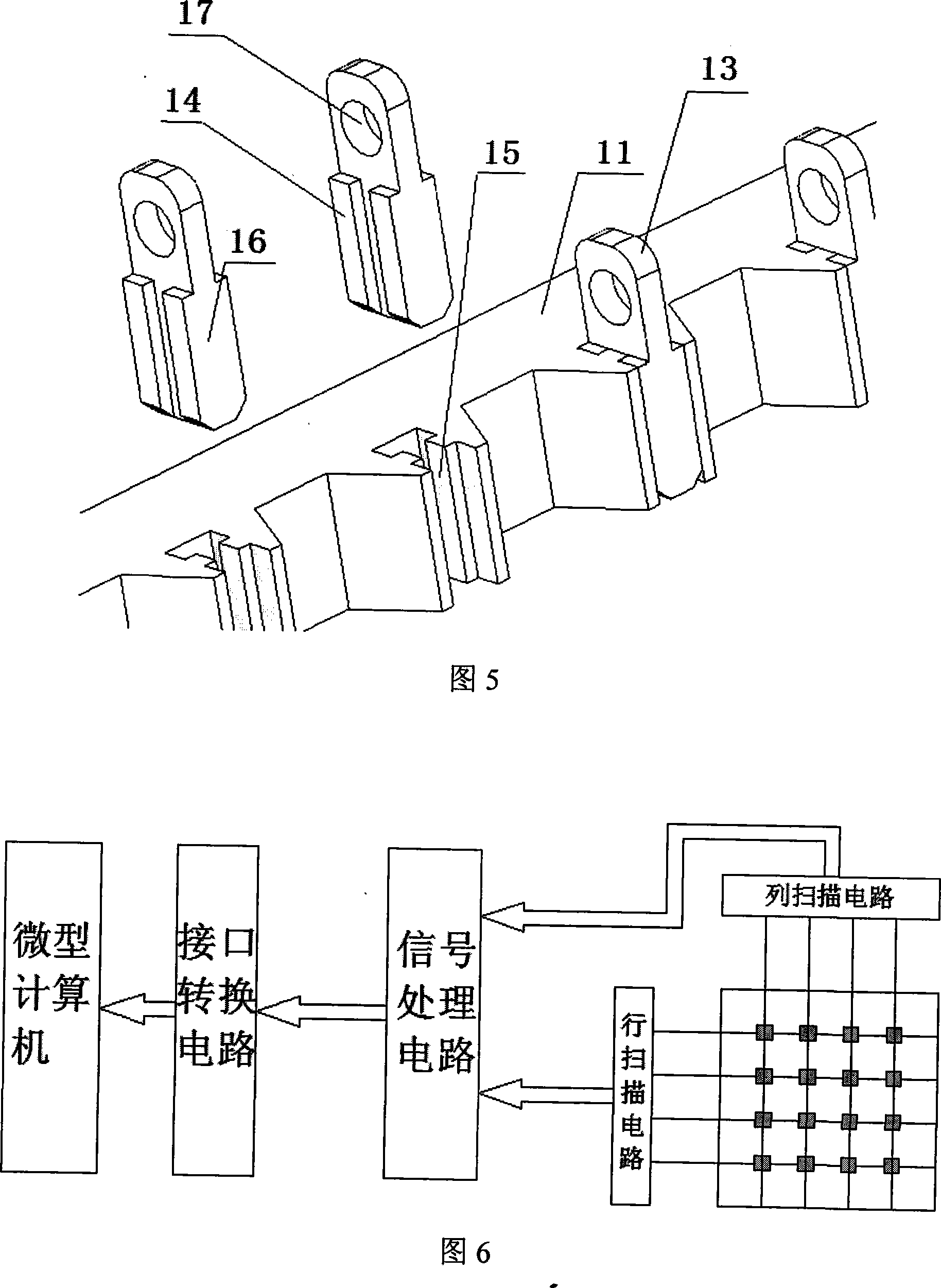

[0023] As shown in Fig. 1 and Fig. 2, a grid pressure sensing chip includes an insulating bottom layer 1 and an insulating upper layer 8, and a row electrode framework layer 2 and a column electrode framework layer 6 are arranged between the insulating bottom layer 1 and the insulating upper layer 9; Four row electrodes 3 are arranged at equal intervals in the row electrode framework layer 2, and four column electrodes 7 are arranged at equal intervals in the column electrode framework layer 6. The row electrodes 3 and the column electrodes 7 form a grid distribution, and the row and column electrodes 3, 7 extends to both sides of the respective structure layers to form row and column electrode external contacts 9 and 9' respectively; an intermediate layer 4 is arranged between the row electrode structure layer 2 and the column electrode struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com