PET/blast furnace slag composite cement-based wave-absorbing material and preparation method thereof

A blast furnace slag and wave absorbing material technology, which is applied in the intersection of electromagnetics and material science, can solve the problems of high density and thickness, narrow absorption frequency band, and high cost, and achieves low density and thickness, wide absorption frequency band and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

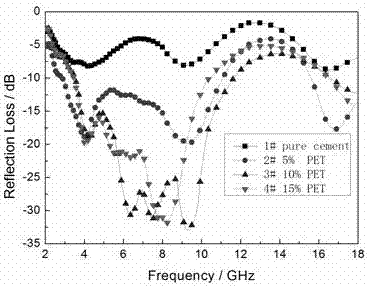

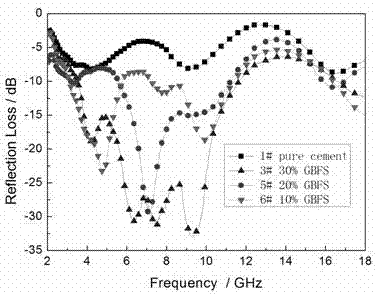

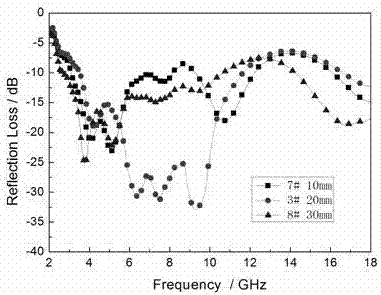

Embodiment 1(2

[0041] The dosage of each raw material of the PET / blast furnace slag composite cement-based wave-absorbing material in this embodiment is shown in Table 1. The preparation method of the PET / blast-furnace slag composite cement-based wave-absorbing material includes the following steps:

[0042] S1. Weigh the raw materials in percentage by weight, put PET chips, cement, and blast furnace slag into the mortar mixer, and then add water to form a cement slurry with a water-cement ratio of 0.35. Among them, water is added twice, and poured into the first 2 / 3 of the total volume of water, after stirring for 5 minutes, pour in the remaining amount of water, and stir for another 5 minutes to obtain cement paste;

[0043] S2. Add wave absorbing agent and polypropylene fiber to the cement paste prepared in step S1, stir for 5 minutes, pour into the mold, vibrate for 1 minute, and scrape the surface to obtain a sample;

[0044] S3. Water the sample prepared in step S2 for 24 hours at room...

Embodiment 2(3

[0046]The dosage of each raw material of the PET / blast furnace slag composite cement-based wave-absorbing material in this embodiment is shown in Table 1. The preparation method of the PET / blast-furnace slag composite cement-based wave-absorbing material includes the following steps:

[0047] S1. Weigh the raw materials in percentage by weight, put PET chips, cement, and blast furnace slag into the mortar mixer, and then add water to form a cement slurry with a water-cement ratio of 0.35. Among them, water is added twice, and poured into the first 2 / 3 of the total volume of water, after stirring for 5 minutes, pour in the remaining amount of water, and stir for another 5 minutes to obtain cement paste;

[0048] S2. Add wave absorbing agent and polypropylene fiber to the cement paste prepared in step S1, stir for 5 minutes, pour into the mold, vibrate for 1 minute, and scrape the surface to obtain a sample;

[0049] S3. Water the sample prepared in step S2 for 24 hours at room ...

Embodiment 3(4

[0051] The dosage of each raw material of the PET / blast furnace slag composite cement-based wave-absorbing material in this embodiment is shown in Table 1. The preparation method of the PET / blast-furnace slag composite cement-based wave-absorbing material includes the following steps:

[0052] S1. Weigh the raw materials in percentage by weight, put PET chips, cement, and blast furnace slag into the mortar mixer, and then add water to form a cement slurry with a water-cement ratio of 0.35. Among them, water is added twice, and poured into the first 2 / 3 of the total volume of water, after stirring for 5 minutes, pour in the remaining amount of water, and stir for another 5 minutes to obtain cement paste;

[0053] S2. Add wave absorbing agent and polypropylene fiber to the cement paste prepared in step S1, stir for 5 minutes, pour into the mold, vibrate for 1 minute, and scrape the surface to obtain a sample;

[0054] S3. Water the sample prepared in step S2 for 24 hours at room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com