Light optics system for microlithography

An illumination optical system and optical system technology, applied in the field of microlithography, can solve problems such as large loss, spectral line energy that cannot meet the requirements of exposure, and mercury lamp energy not concentrated, so as to achieve low energy, improve uniform light effect, Guaranteed the effect of the size of the lighting field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] The technical solution of the schematic diagram of the present invention has been provided, and the light propagation path and the specific implementation of the optical system are described below:

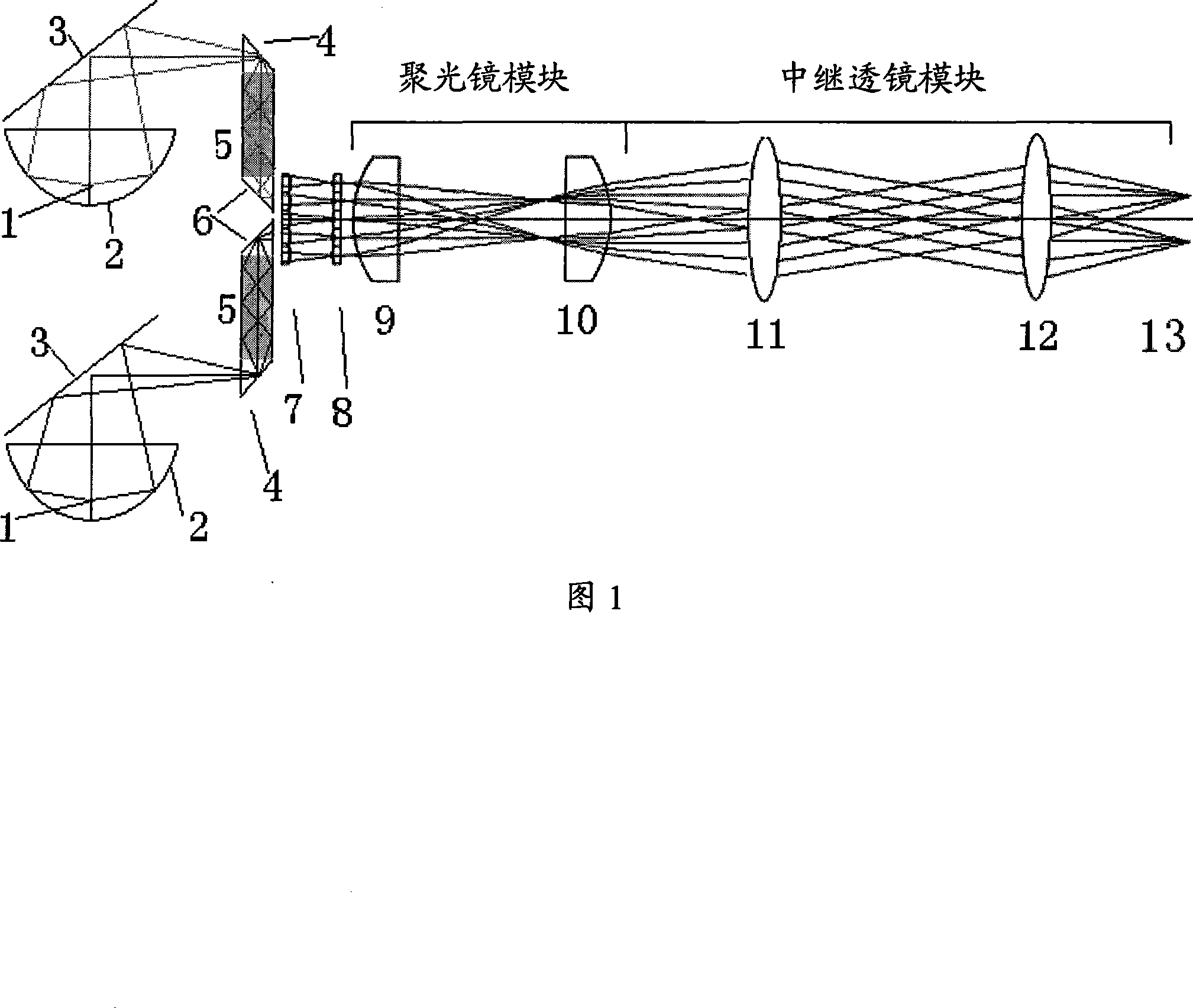

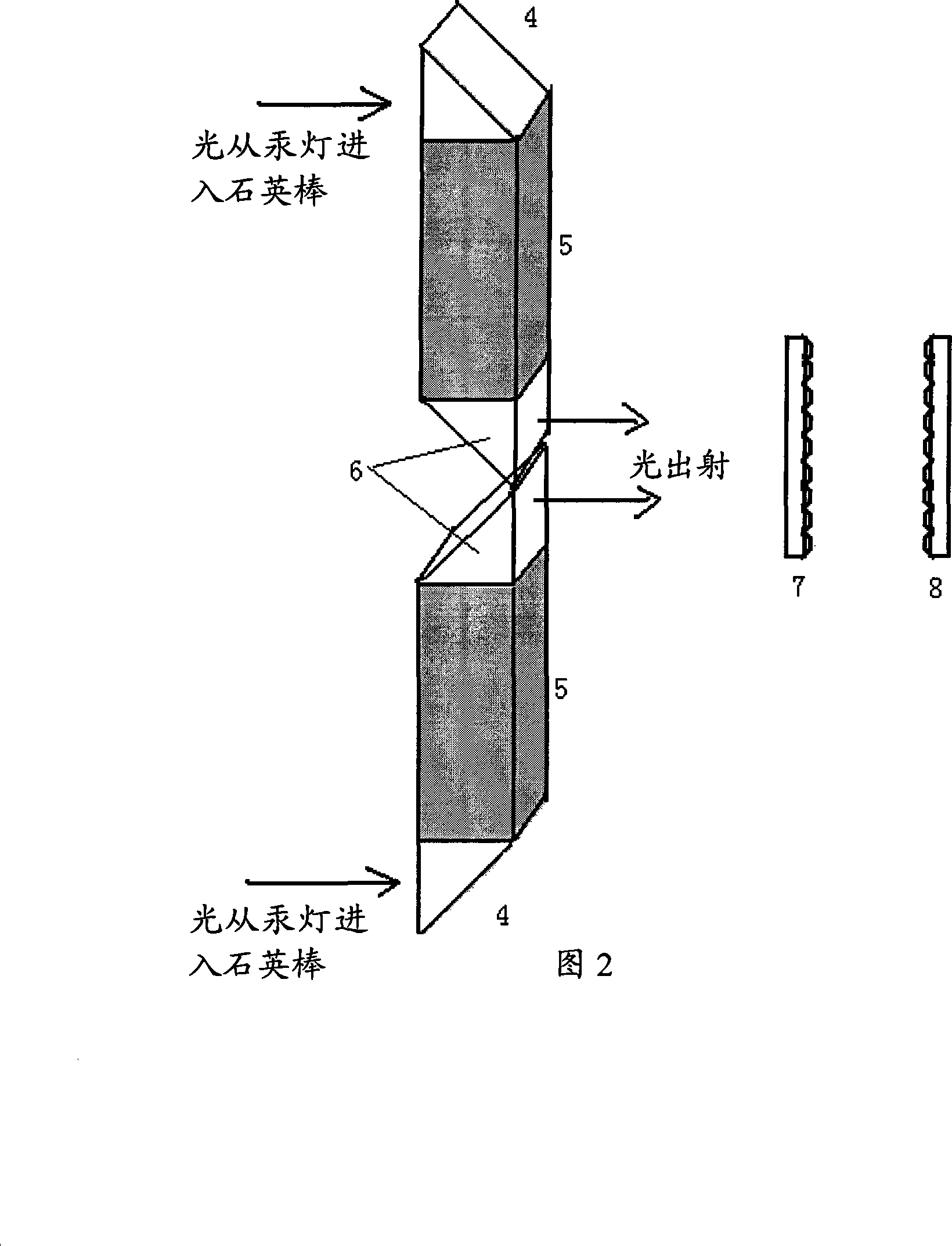

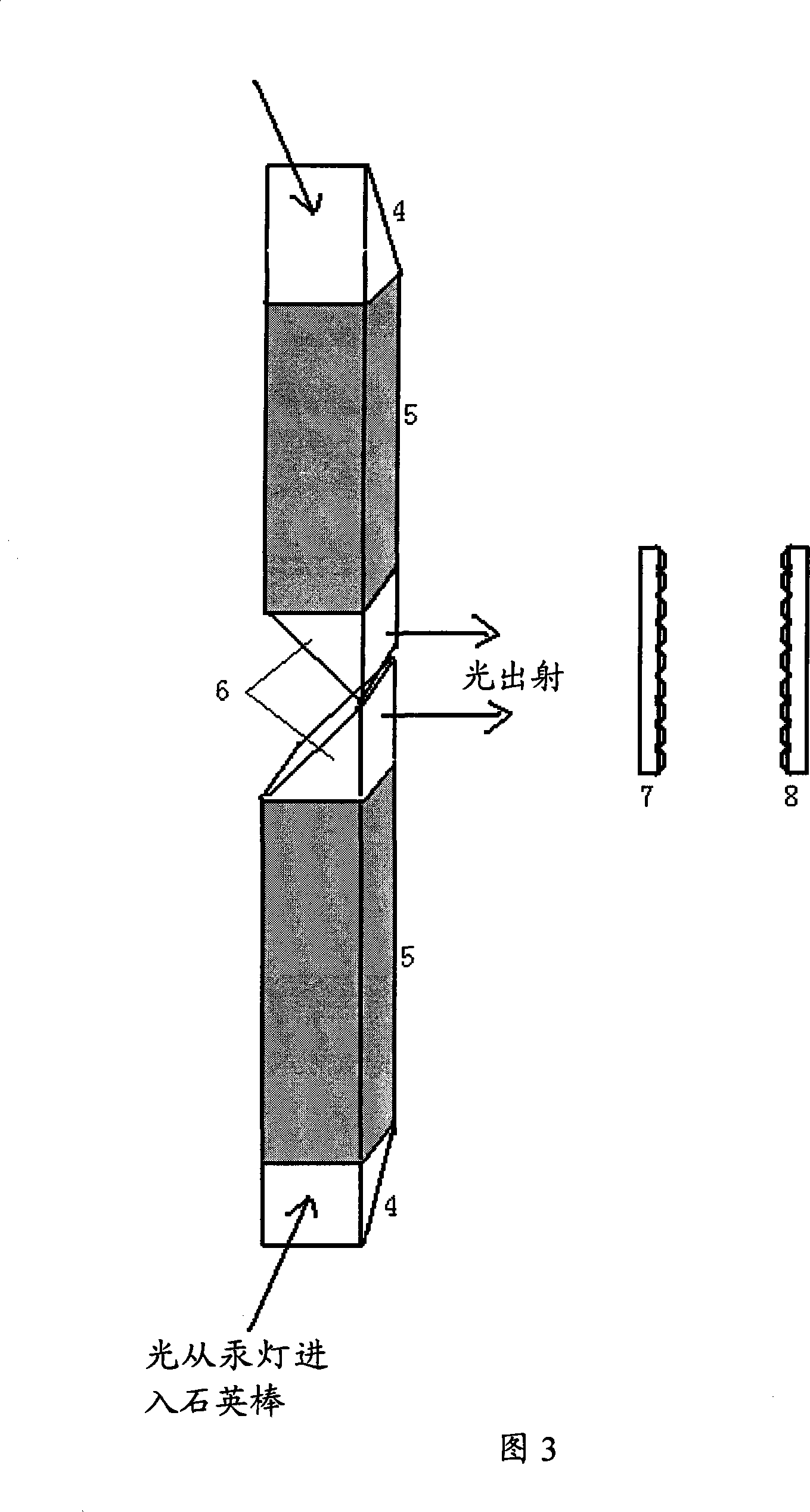

[0025] Fig. 1 (Fig. 1 is the optical path diagram of the embodiment of the present invention adopting two high-pressure mercury lamp light sources) the high-pressure mercury lamp light source 1 filament position is at the focal point F1 inside the ellipsoid reflector 2, so that the image of the light source can be guaranteed to be at the focal point Correct position of F2. The positions of the two mercury lamps can be placed according to actual needs, but after reflection by the reflector 3, it should be ensured that the focus of the ellipsoidal reflector is at the entrance of the quartz rod 5. The light passes through the incident end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com