A maintenance method of plasma etching device

A kind of etching equipment and plasma technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of lower yield, lower efficiency, and affect the silicon wafer processing process, so as to save time, improve efficiency, The effect of ensuring the quality of silicon wafer processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0053] Its specific implementation method comprises the following steps:

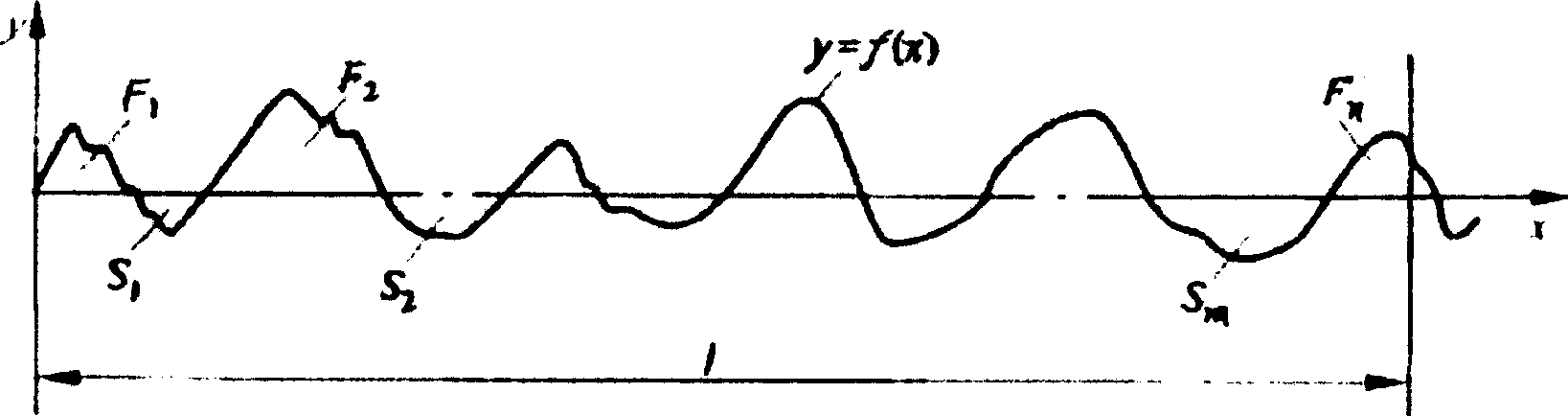

[0054] In the first step, the corresponding relationship between the performance parameters of the products in the plasma etching equipment and the surface roughness inside the reaction chamber of the plasma etching equipment is established.

[0055] In this process, the corresponding relationship between the inner surface area S of the reaction chamber and the roughness value Ra of the inner surface of the reaction chamber can be established first, including:

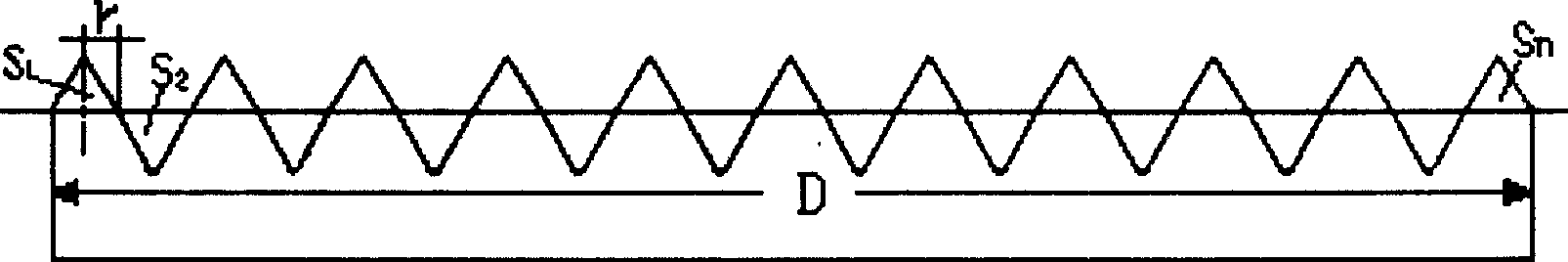

[0056] (1) Establishing a mathematical model of the surface area Sn of the microscopic particles on the inner surface of the reaction chamber and its surface roughness value Ra, Sn=fn(Ra).

[0057] Firstly, the model of the surface particles of the quartz component is established, and the particle radius r under different roughness is calculated according to the definition of roughness. The quartz components in the etching machine mainly refer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com