Nonaqueous electrolyte battery, battery pack and vehicle

A non-aqueous electrolyte and battery pack technology, which is applied in the direction of non-aqueous electrolyte batteries, non-aqueous electrolyte battery electrodes, organic electrolyte batteries, etc., can solve the problems of reduced cycle life and insufficient reduction resistance of non-aqueous electrolyte batteries, and achieve The effect of excellent cycle performance and high current performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

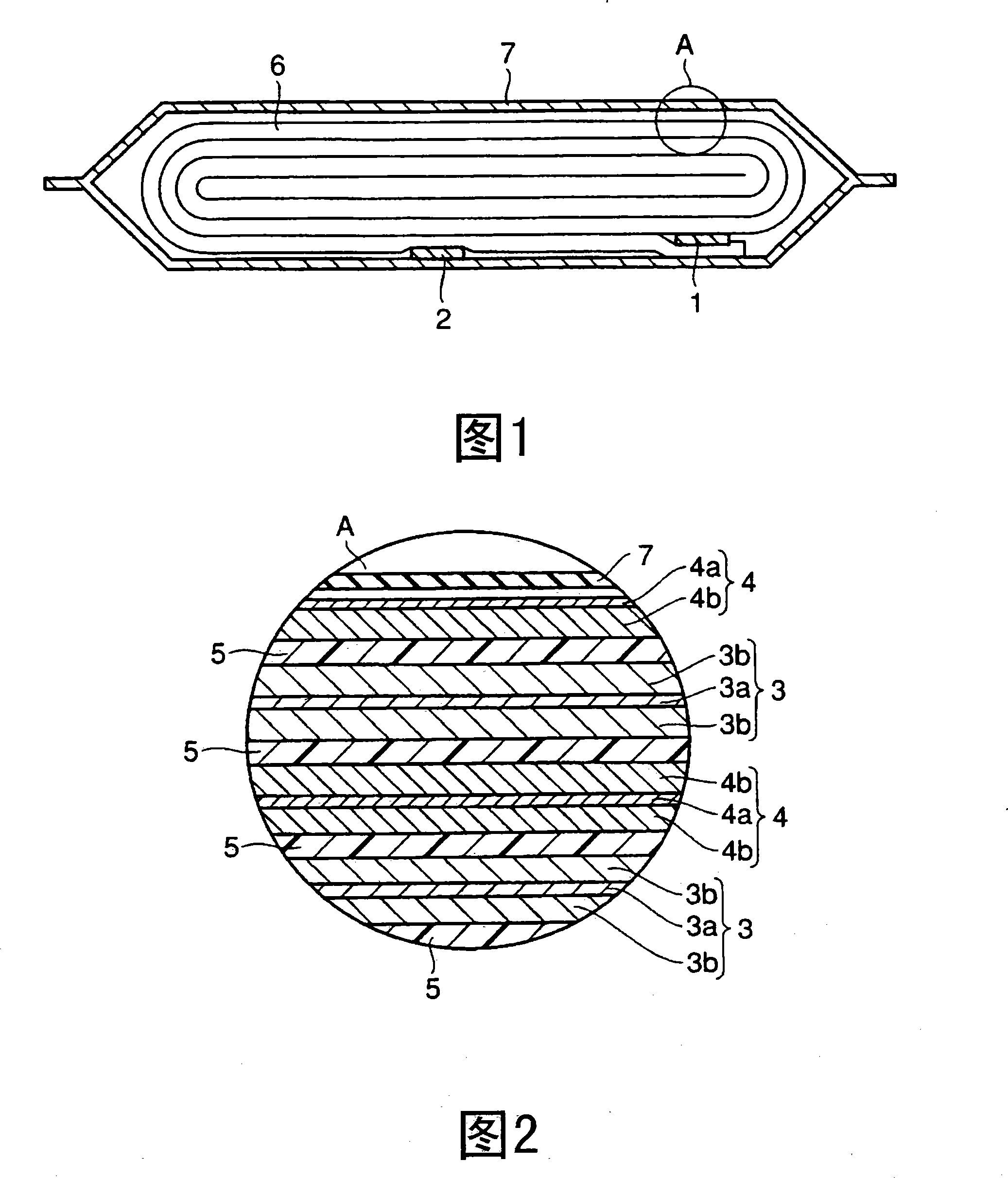

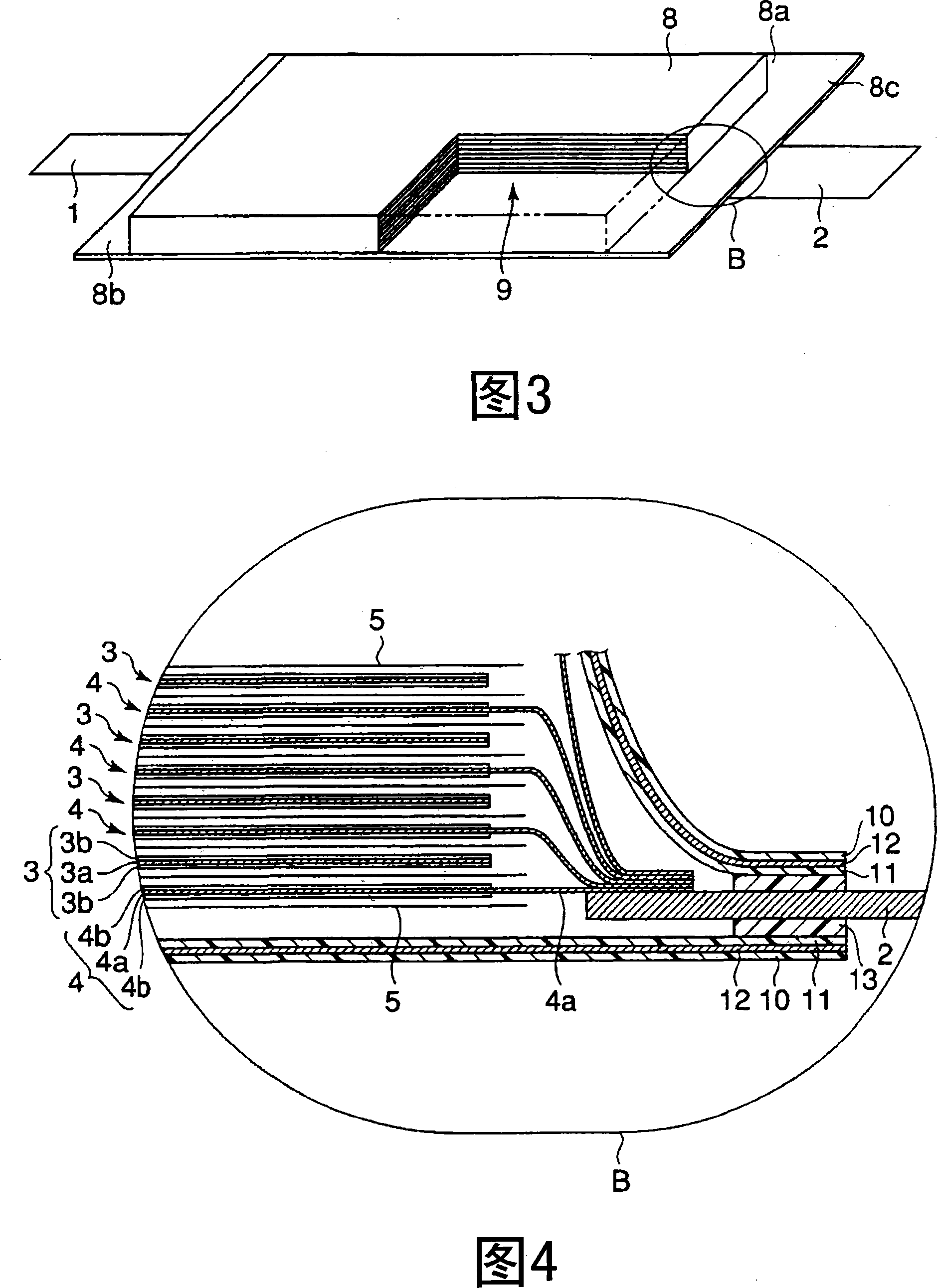

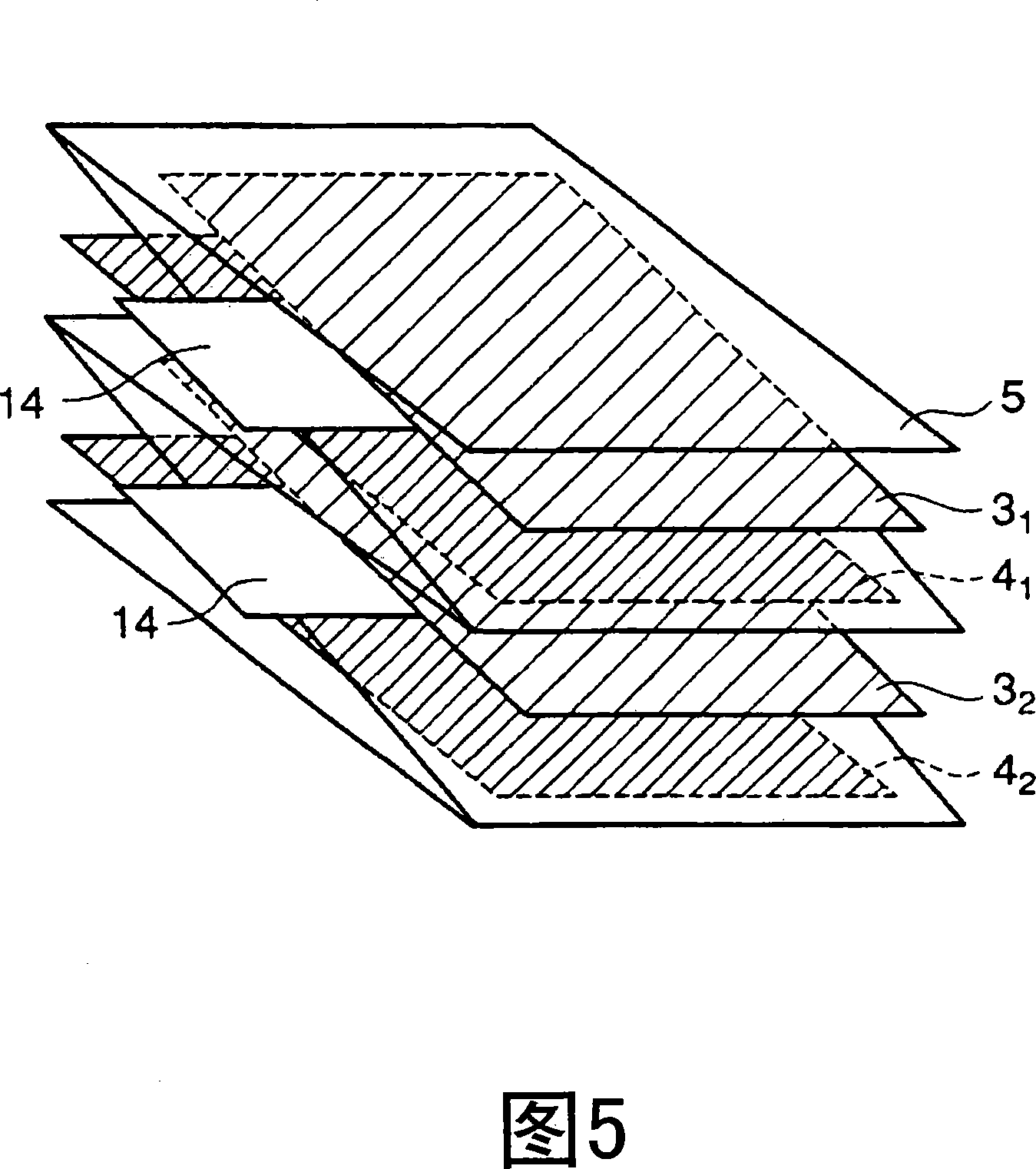

[0046] An example of a nonaqueous electrolyte battery according to an embodiment of the present invention will be described with reference to FIG. 1 and FIG. 2 . FIG. 1 is a schematic cross-sectional view of a flat non-aqueous electrolyte secondary battery according to an embodiment of the present invention. FIG. 2 is a schematic partial cross-sectional view showing in detail the circled portion shown in A in FIG. 1 .

[0047] As shown in FIG. 1 , a flat wound electrode group 6 is housed in a case member 7 . The wound electrode group 6 has a structure in which the separator 5 is interposed between the positive electrode 3 and the negative electrode 4 and they are wound in a spiral shape. A nonaqueous electrolyte is held in wound electrode group 6 .

[0048] As shown in FIG. 2 , the negative electrode 4 is located at the outermost periphery of the wound electrode group 6, and on the inner peripheral side of the negative electrode 4, there are separators 5, positive electrodes...

no. 2 approach

[0182] The battery pack of the second embodiment has a plurality of non-aqueous electrolyte batteries of the first embodiment as unit cells. Each single battery is arranged in series or in parallel to form a battery pack.

[0183] The battery cell of the first embodiment is suitable for making a battery pack, and the battery pack of the second embodiment has excellent cycle performance. This is explained below.

[0184] If the high-current performance and charge-discharge cycle performance of the non-aqueous electrolyte battery are improved, individual differences in battery capacity and individual differences in impedance can be greatly reduced. As a result, for example, in assembled batteries connected in series, it is possible to reduce variations in battery voltage at the time of full charge due to individual differences in battery capacity. Therefore, the battery pack of the second embodiment has excellent controllability of the assembled battery, and can improve cycle ...

no. 3 approach

[0198] The automobile of the third embodiment has the battery pack of the second embodiment. In general, a large current of about 10C or more flows through a battery pack for automotive use. Since the cells of the first embodiment have excellent high-current performance, temperature differences or impedance differences between cells during high-current charging and discharging can be reduced. As a result, since a part of the single cells can be prevented from being overcharged or overdischarged, the battery pack of the second embodiment has excellent cycle performance. Therefore, the automobile of the third embodiment can maintain excellent characteristics of the drive source. Examples of the automobile referred to here include a hybrid electric vehicle with two to four wheels, an electric vehicle with two to four wheels, and a moped bicycle.

[0199] Figures 9 to 11 show a hybrid vehicle in which an internal combustion engine and a battery-driven electric motor are combined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com