Electrical gearbox with continuous variation

A gear transmission and electric transmission technology, applied in the direction of motors, electromechanical devices, electric vehicles, etc., can solve problems such as low overall efficiency, and achieve the effect of high overall efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

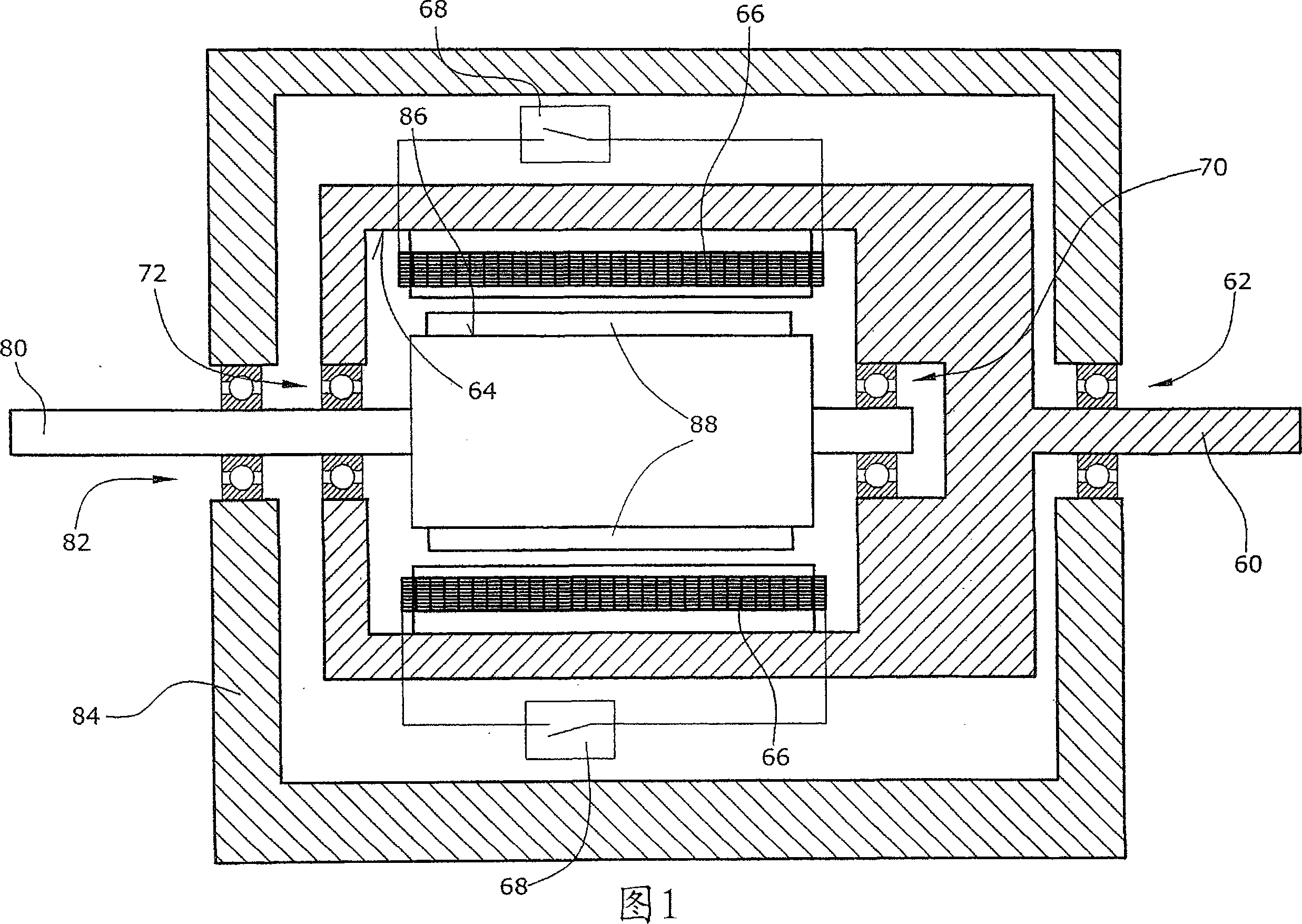

[0026] In a first preferred embodiment, the electric transmission of the invention (FIG. 1) comprises an input shaft 80 connectable to a drive. For example, the drive device can be an internal combustion engine.

[0027] Further, the transmission device (or referred to as a transmission) includes an output shaft 60, and the input shaft 80 and the output shaft 60 are connected through a power transmission device. The input and output shafts are not physically connected. An electric field is established between the input shaft 80 and the output shaft 60 , which induces a torque, which is a drag torque and is load dependent, causing the output shaft 60 to follow the input shaft 80 .

[0028] Since the drag torque of the transmission, like all other mechanical resistances in the transmission, always results in the output shaft 60 being pulled by the input shaft 80, the mechanical efficiency of the transmission is increased as provided by the present invention.

[0029] In order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com