Method for preparing microcapsule coated microvesicle ultrasonic contrast medium

A technology of ultrasound contrast agent and microcapsule, which is applied in the direction of echo/ultrasound imaging agent, etc., which can solve the problems of disappearance and unstable acoustic properties of microbubble contrast agents, and achieve the effects of preventing dispersion, improving weak bonding, and good acoustic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

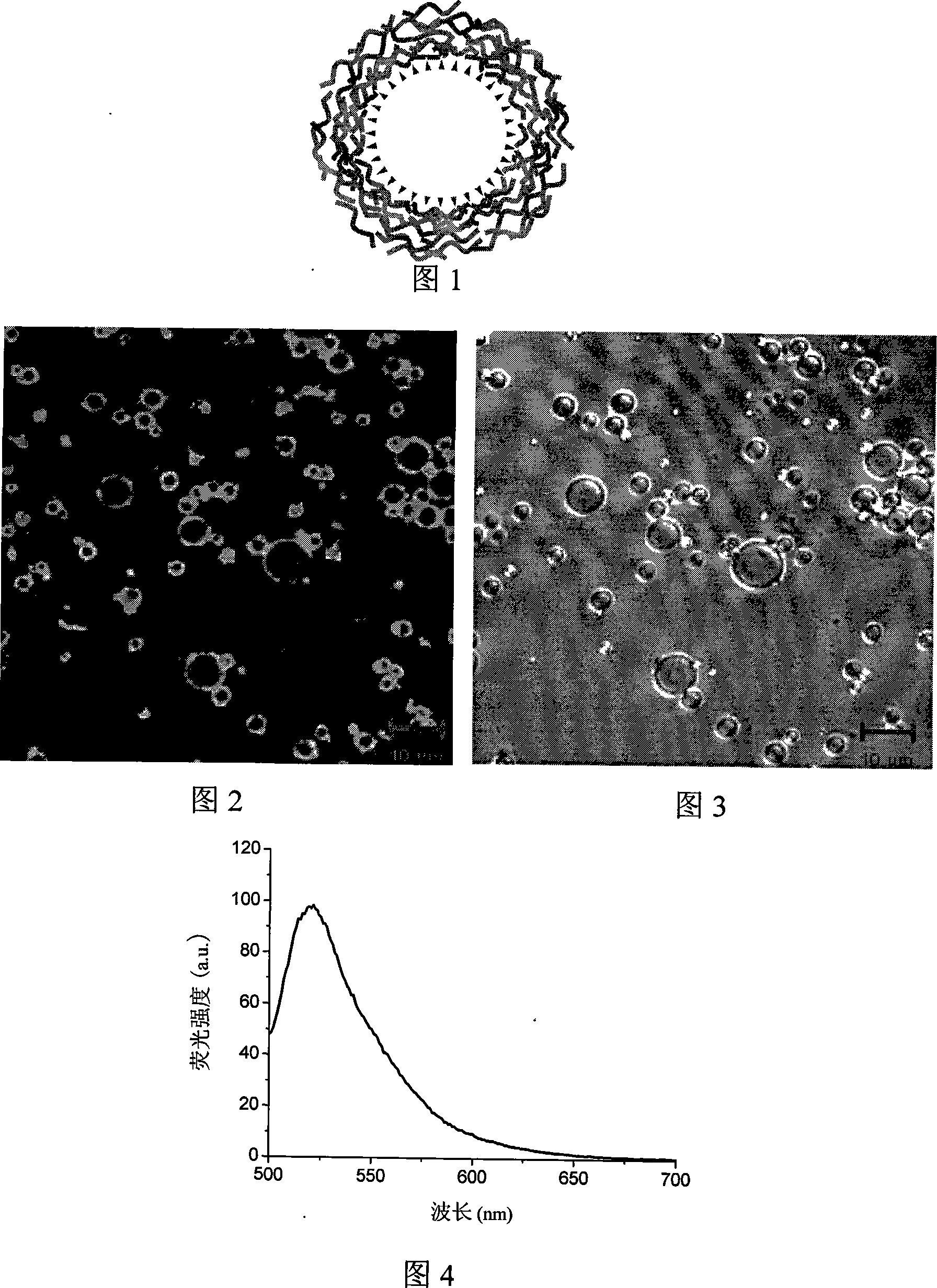

[0015] Specific Embodiment 1: The microbubble ultrasonic contrast agent coated with microcapsules in this embodiment is prepared as follows: add microbubbles with a negative charge on the surface to a concentration of 0.001-1000 mg / mL and a volume of microbubble volume 1 ~100 times, positively charged bioactive material solution is adsorbed for 0.5~100min, left standing or centrifuged, and the upper layer of microbubbles is washed with normal saline or PBS buffer solution with a pH value of 7.0~8.0, and then added to a concentration of 0.001~ 1000mg / mL, 1-100 times the volume of microbubbles, and negatively charged bioactive material solution for 0.5-100min, let stand or centrifuge, and then wash the upper layer of microbubbles with normal saline or PBS with a pH value of 7.0-8.0 Washing with buffer solution; the microbubble ultrasound contrast agent coated with microcapsules is obtained.

[0016] The surface of the microbubble ultrasound contrast agent coated with microcapsul...

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the microbubbles in step 1 are contrast agent microbubbles based on surfactants, or encapsulated with proteins, polymer materials, lipids or carbohydrates. Membrane contrast agent microbubbles. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the positively charged bioactive material in step 1 is one of polyelectrolytes, drugs, bioactive factors, DNA sequences, and targeting ligands or a combination of several. Others are the same as in the first embodiment.

[0019] In this embodiment, the positively charged bioactive material is composed of two or more substances and mixed in any ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com