Apparatus and method for removing grains with combined action of sound wave and additional seed grain

A seed particle, combined action technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as inability to effectively remove respirable particles, difficult to ensure long-term stable and reliable work, and poor effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

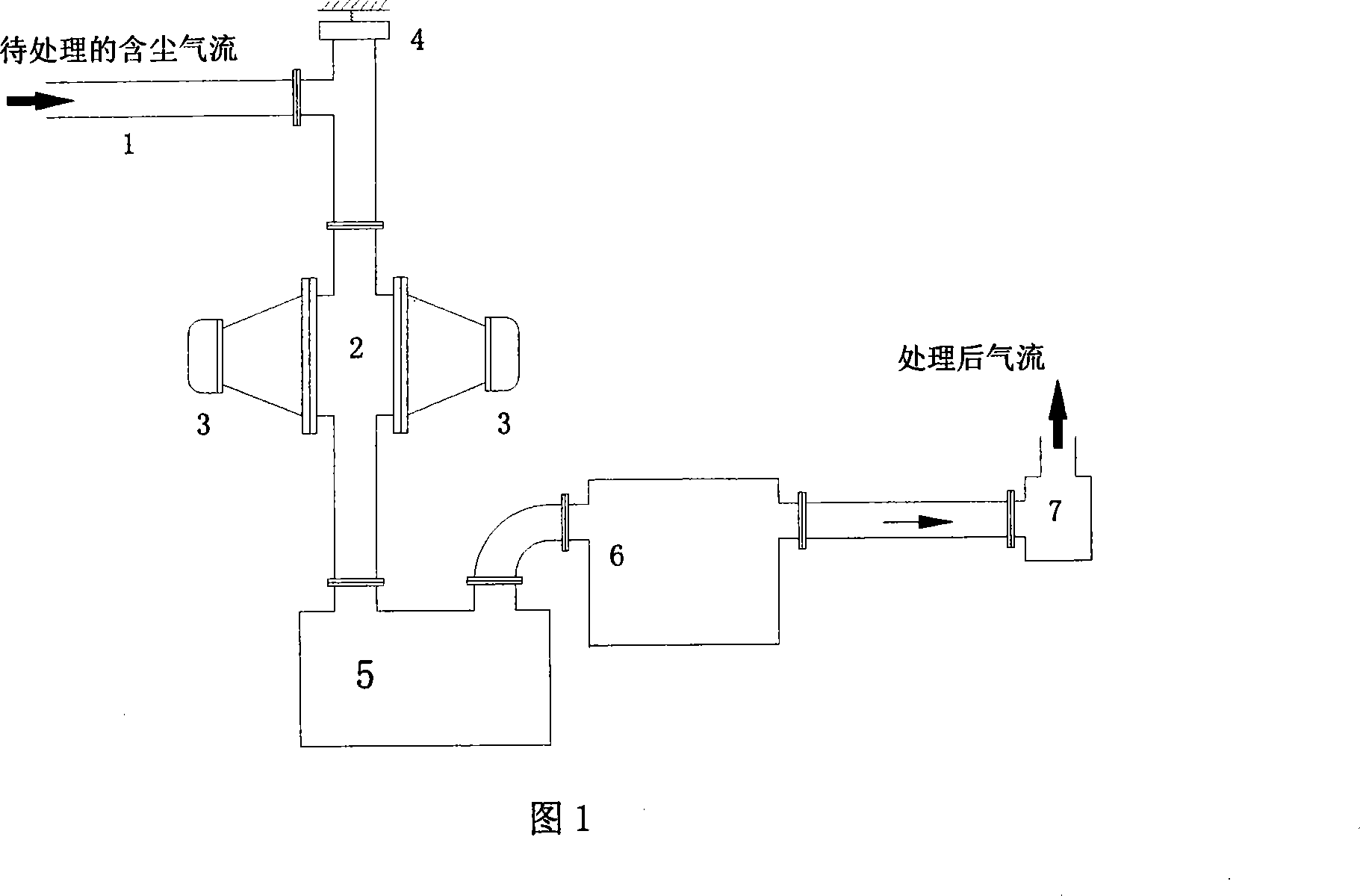

[0040] The whole device of the present invention is divided into three parts as shown in Fig. 1: sound source; dust-laden air flow channel system (agglomeration chamber); additional particle system and follow-up conventional dust removal equipment. The follow-up conventional dust removal equipment in this figure, as an example, adopts two-stage settling chamber separation, and has a corresponding cutting particle size. In actual use, single-stage or multi-stage conventional dust removal equipment can be used.

[0041] The specific connection method is as follows: one end of the horizontal channel of the dust-laden airflow inlet is connected to the upper end of the vertical sound wave agglomeration chamber; the vibration feeding device for adding particles is connected to the vertical sound wave agglomeration chamber with the top; Connecting flanges are respectively installed on the two sides, and are connected with two different-diameter connecting pipes arranged horizontally;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com