Method for producing soakage controllable zinc oxide nano-stick array thin film

A zinc oxide nanorod, wettability technology, applied in the field of nanomaterials, can solve problems such as temperature sensitivity, limited application, and limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

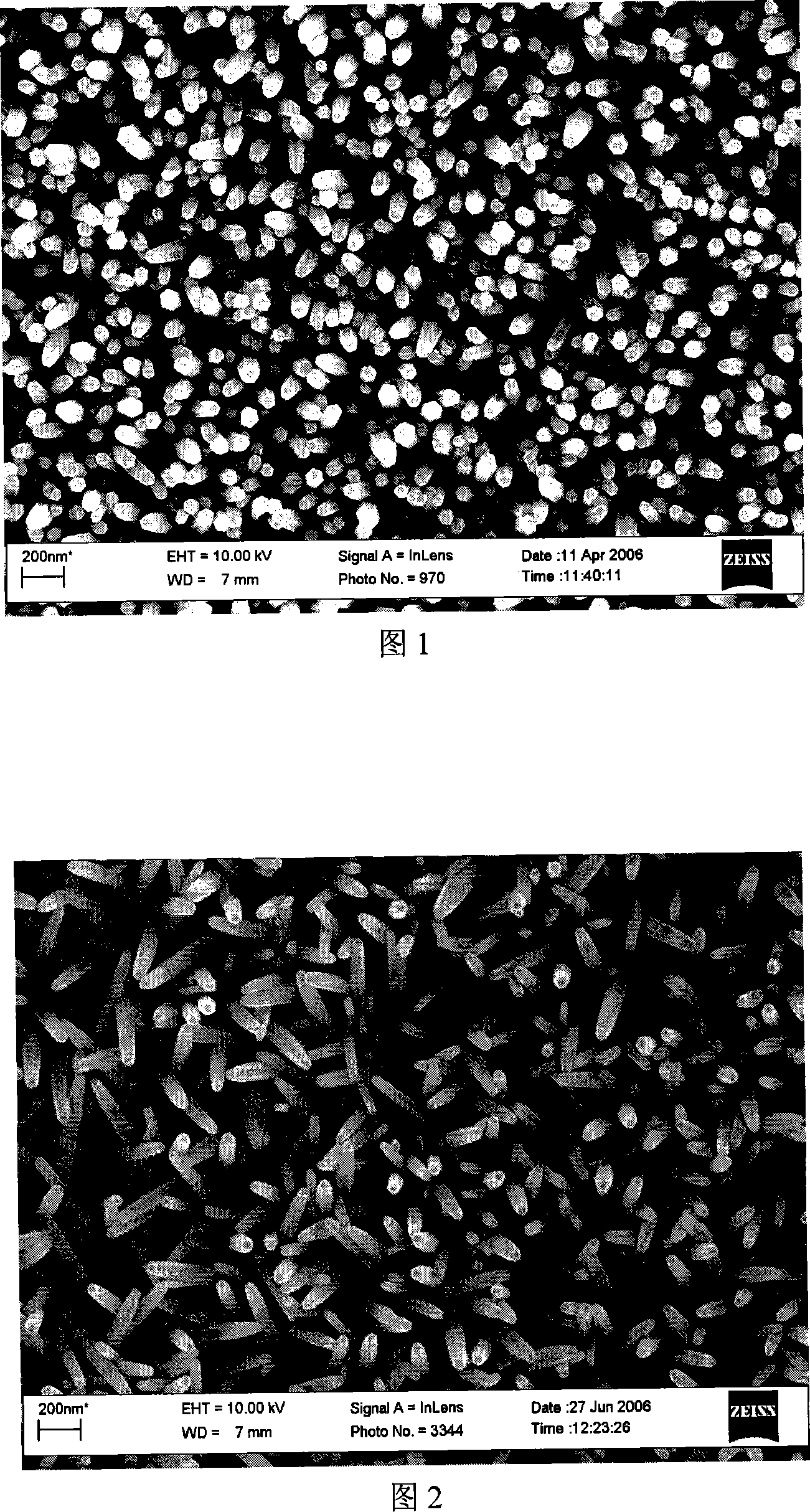

[0024] Example 1: When the density is controlled by controlling the colloid, the above conditions are kept unchanged, and the colloid concentration is selected to be 1mol / L, 0.1mol / L, 0.001mol / L, and 0.0001mol / L.

Embodiment 2

[0025] Example 2: When controlling the density by controlling the number of times of glue rejection, the number of times of glue rejection is 1, 3, 5, 7, 9 times.

Embodiment 3

[0026] Example 3: When the density is controlled by controlling the annealing temperature, the substrate after spun glue is annealed at 500° C., and the annealing time is 5 min, 30 min and 60 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com