Method and apparatus for processing fluid-bed of oily wastewater

A treatment method and fluidized bed technology are applied to the separation of oily pollutants and water bodies, and the regeneration of oil-absorbing resins under the fluidized bed process. , In the field of high oil-absorbing resin, it can solve the problems of increased fluidized bed resistance, slow processing speed, and increased pressure drop, and achieve the effects of increasing contact time, avoiding resin extrusion, and avoiding increased resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

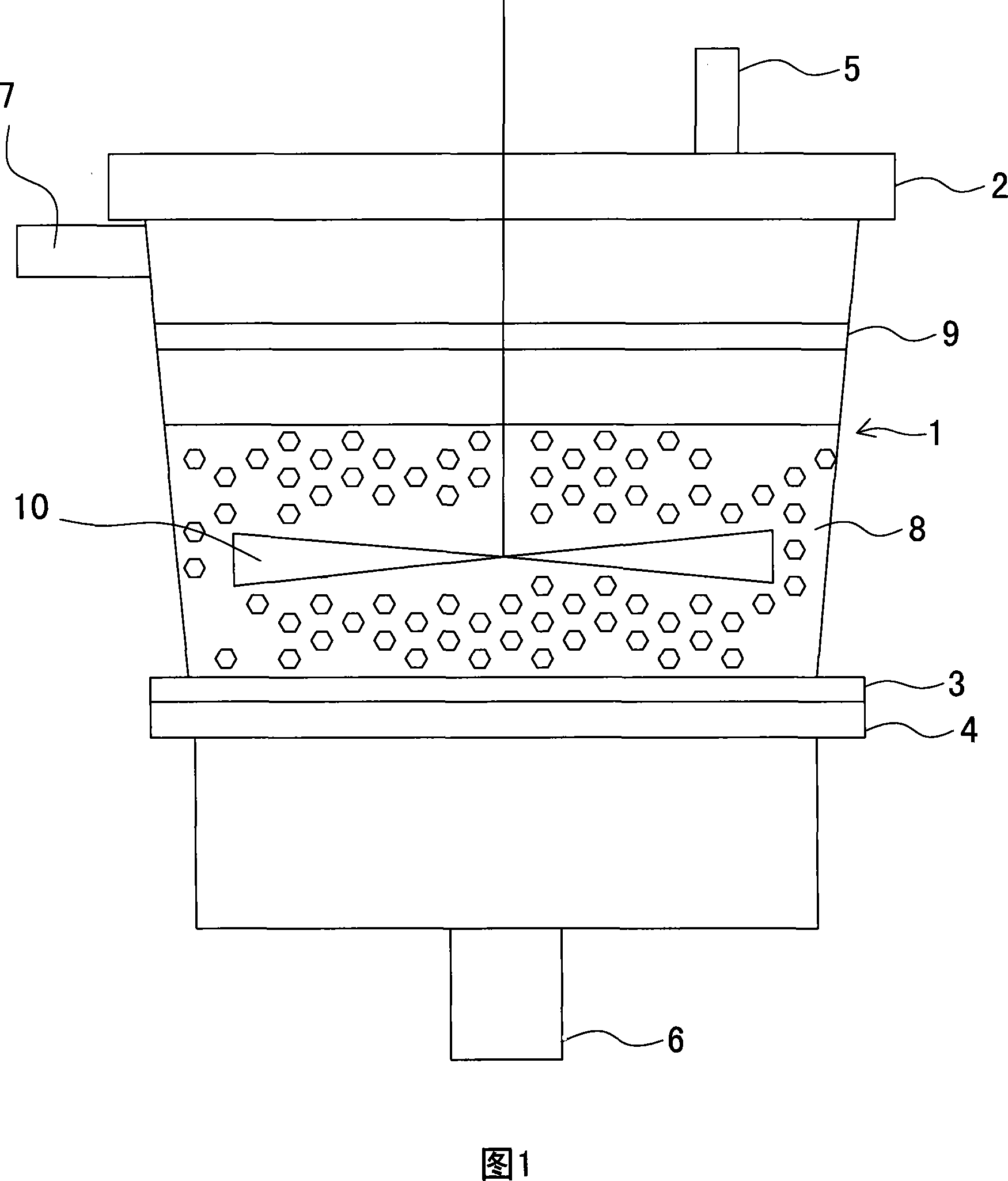

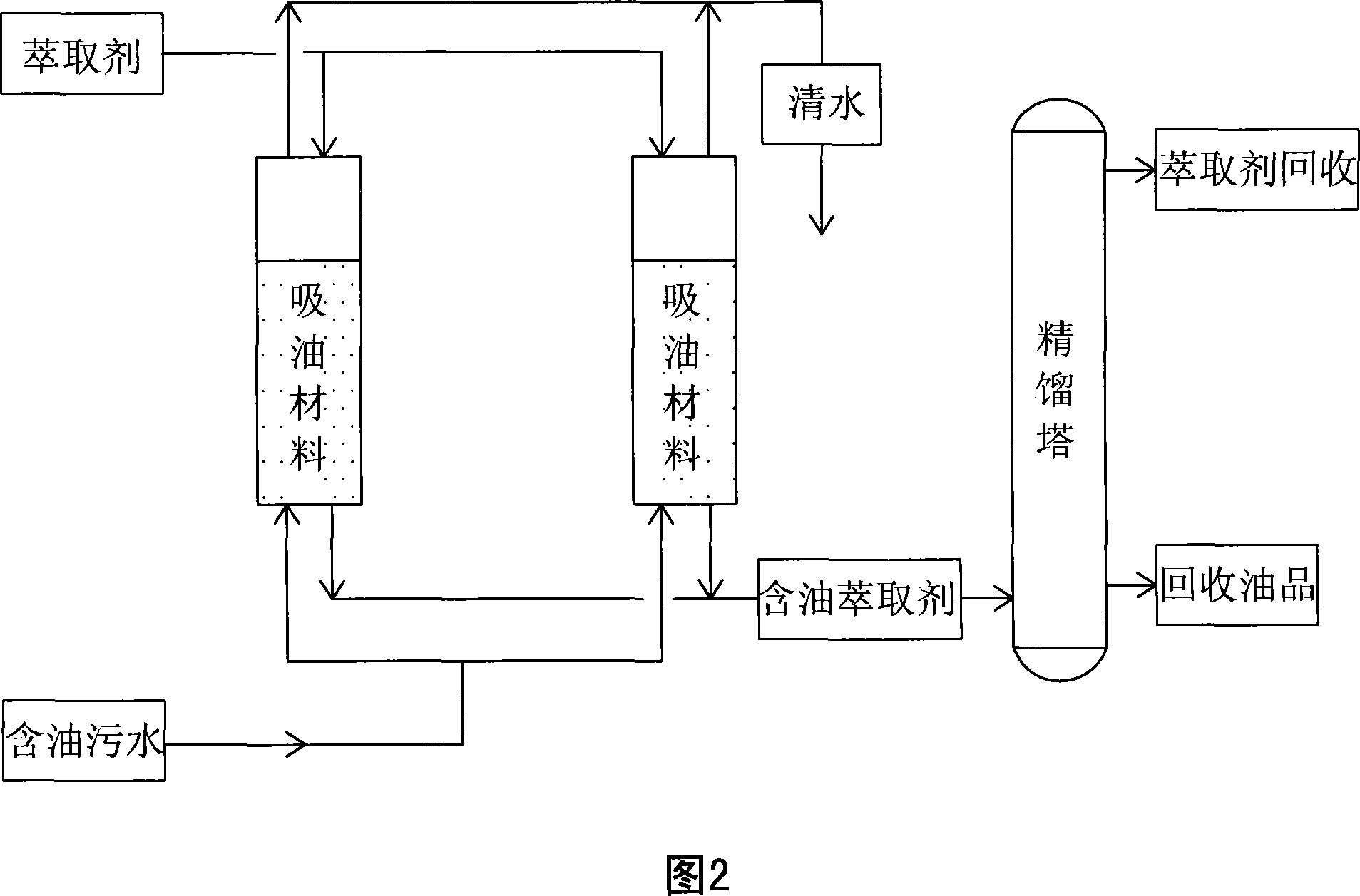

[0024] Embodiment 1: Referring to the accompanying drawing 1, a fluidized bed equipment for treating oily wastewater includes a fluidized bed body 1, an upper head 2 and a lower head respectively connected to the upper and lower ends of the bed body Head 3, the lower head 3 is connected with the lower end of the fluidized bed body through an unloadable flange 4, the upper head 2 is provided with an extractant inlet 5, and the lower head 3 is provided with a waste water inlet 6, the The waste water inlet 6 can be used as the extractant outlet, and a clear water outlet 7 is provided on the upper end wall of the fluidized bed. An oil-absorbing resin bed is provided above the bed 8 with an oil-absorbing resin screen 9 , and an internal stirring device 10 is provided in the bed 8 .

[0025] Embodiments 2 to 5 further describe the oil absorption process involved in the present invention.

Embodiment 2

[0026] Embodiment two: referring to accompanying drawing 1, shown in accompanying drawing 2, use the fluidized bed equipment shown in accompanying drawing 1, with oily waste water (containing 10% (volume content) dimethylbenzene) from the oily waste water of the lower end of fluidized bed Inlet 6 passes through the fluidized bed loaded with high oil-absorbing resin material, the flow rate of oily waste water is 20 liters / hour, the stirring device 10 is not working, the clear water can enter other processes or be directly discharged, and the xylene content in the clear water is 3%.

Embodiment 3

[0027] Embodiment three: use the fluidized bed equipment shown in accompanying drawing 1, with oily waste water (containing 10% (volume content) xylene) from the oily waste water inlet 6 of the lower end of fluidized bed through the flow that is loaded with super oil-absorbing resin material The fluidized bed, the flow rate of oily waste water is 20 liters / hour, the stirring device 10 works, the clear water can enter other processes or be directly discharged, and the xylene content in the clear water is less than 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com