Integrated water purification processing method and device of ultrafiltration membrane coagulation/bioreactor

A bioreactor and treatment device technology, applied in the field of water treatment, can solve problems such as limited removal capacity of dissolved organic matter in water, stability of aquatic organisms, and inability to remove them, so as to reduce maintenance and operation costs, delay membrane fouling, and facilitate maintenance management effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

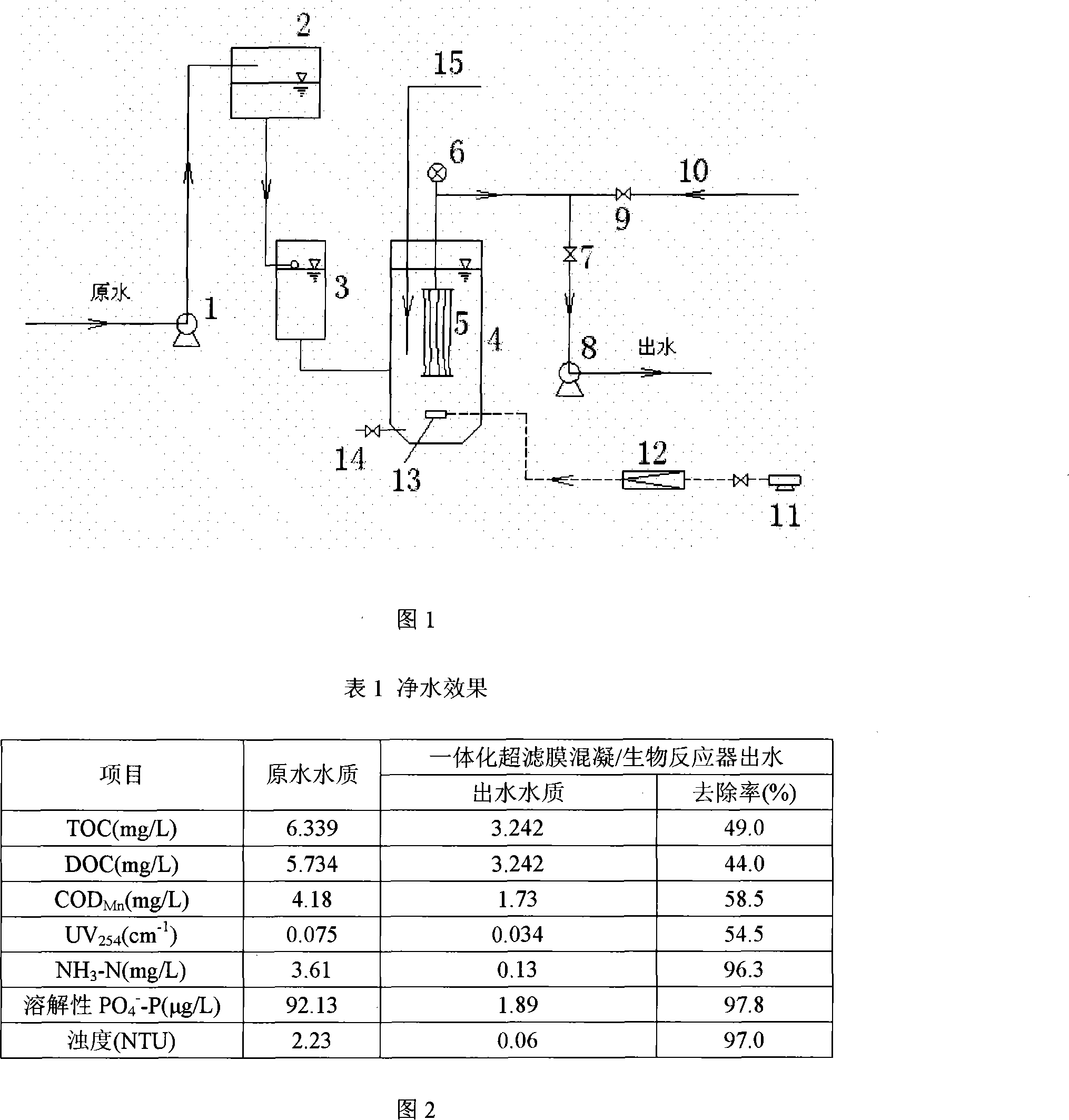

[0023]The integrated ultrafiltration membrane coagulation / bioreactor water purification treatment device shown in Figure 1 is used to treat a certain slightly polluted source water. The raw water to be treated is first lifted by the lift pump 1 to the high-level water tank 2, and then enters the ultrafiltration membrane coagulation / bioreactor 4 through the constant-level water tank 3, and the hydraulic retention time in the reactor is 30 minutes. At the same time, the coagulant is added to the ultrafiltration membrane coagulation / bioreactor 4 by the coagulant dosing system 15, the coagulant is polyaluminum chloride, and the dosage is 10mg / L; the sludge in the reactor The residence time is 20d. The ultrafiltration membrane module 5 adopts the submerged hollow fiber ultrafiltration membrane provided by Hainan Lisheng Water Purification Technology Co., Ltd., the membrane pore size is 0.01 μm, and the membrane material is polyvinyl chloride. The water flux of the ultrafiltration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com