Double-hanging point headstock gear of large span shutter

A technology of double lifting points and hoist, which is applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problems that it is difficult to meet the rigidity value of the hoist, and achieve light weight, reduced axial size, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

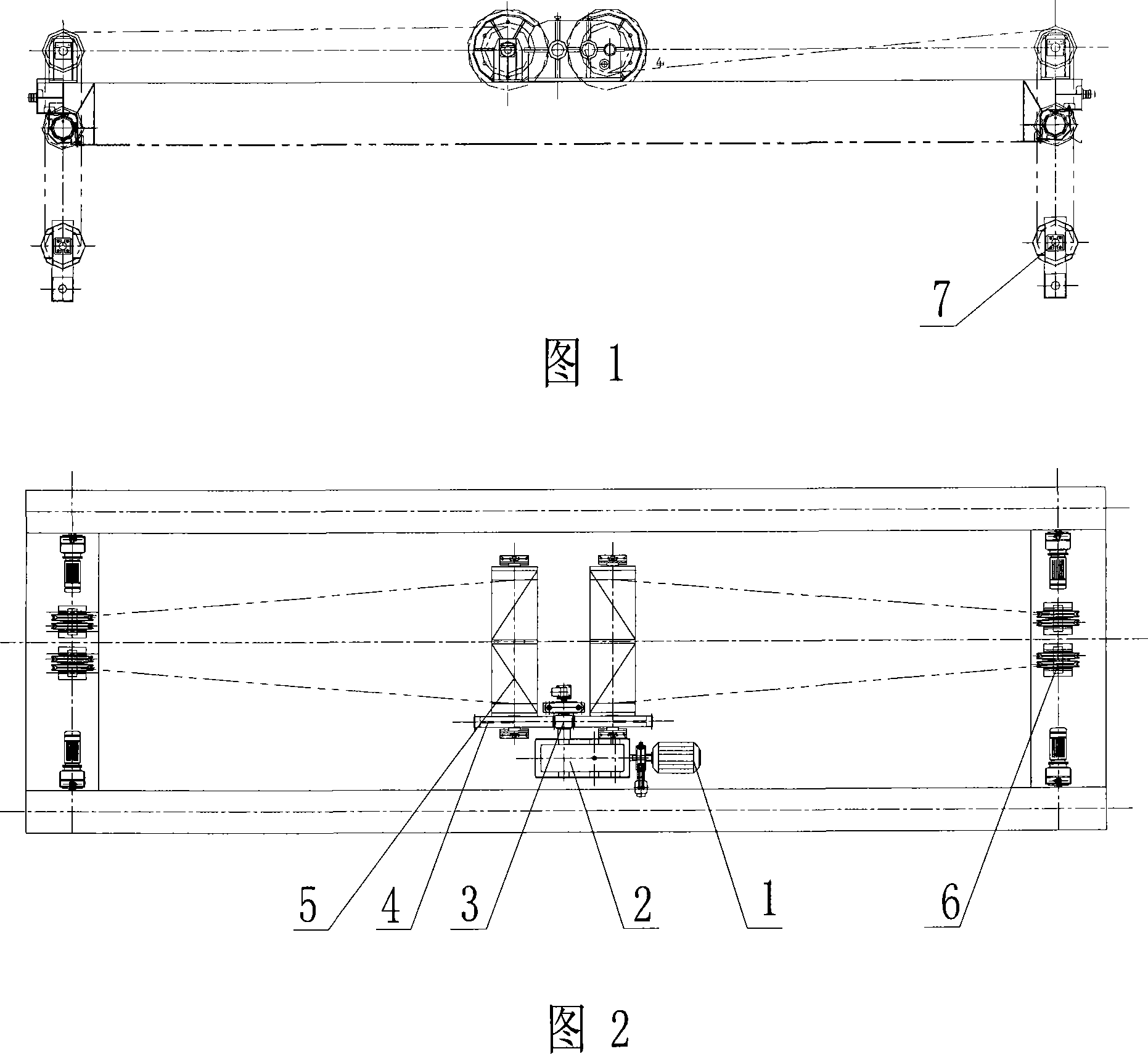

[0013] Referring to accompanying drawings 1 and 2 of the description, the hoist with double lifting points for a large-span gate of the present invention includes a motor 1, a reducer 2 connected to the motor 1 through a brake, a reel 5, a fixed pulley 6 and a gate lifting point. The movable pulley 7, which also includes a central pinion 3 rigidly connected to the output shaft of the low-speed transmission of the reducer 2, and a bull gear 4 meshing with the central pinion 3, the bull gear 4 is integrated with the reel 5 Structure, reel 5 is wound with the steel wire rope that controls gate lift by fixed pulley 6 and movable pulley 7. The big gears 4 are symmetrically arranged one on the left and one on the left, and the rope grooves of the left and right reels 5 have opposite directions of rotation, and two steel wire ropes are respectively fixed from the two ends of the reel 5. device. The reducer 2 is a vertical axis reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com