Miniature ultra-optical spectrum integrated optical filter and its production method

A filter and hyperspectral technology, applied in the fields of filter, optics, spectrum investigation, etc., can solve the problems of rough etching surface, difficult to control the depth of etching, unable to independently design the optical characteristics of the channel, etc., to achieve high resolution rate, the effect of overcoming thickness inconsistencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and embodiments.

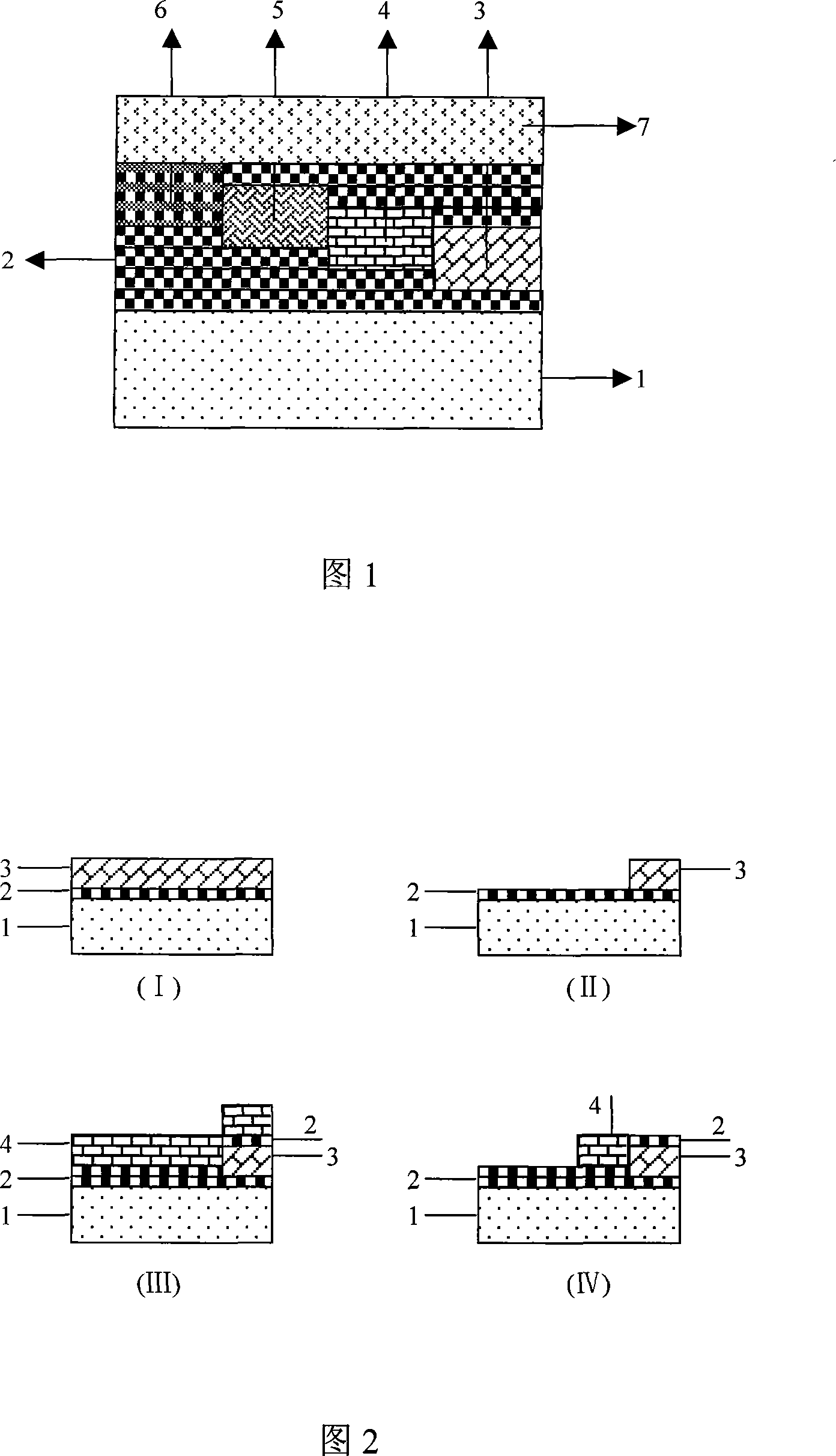

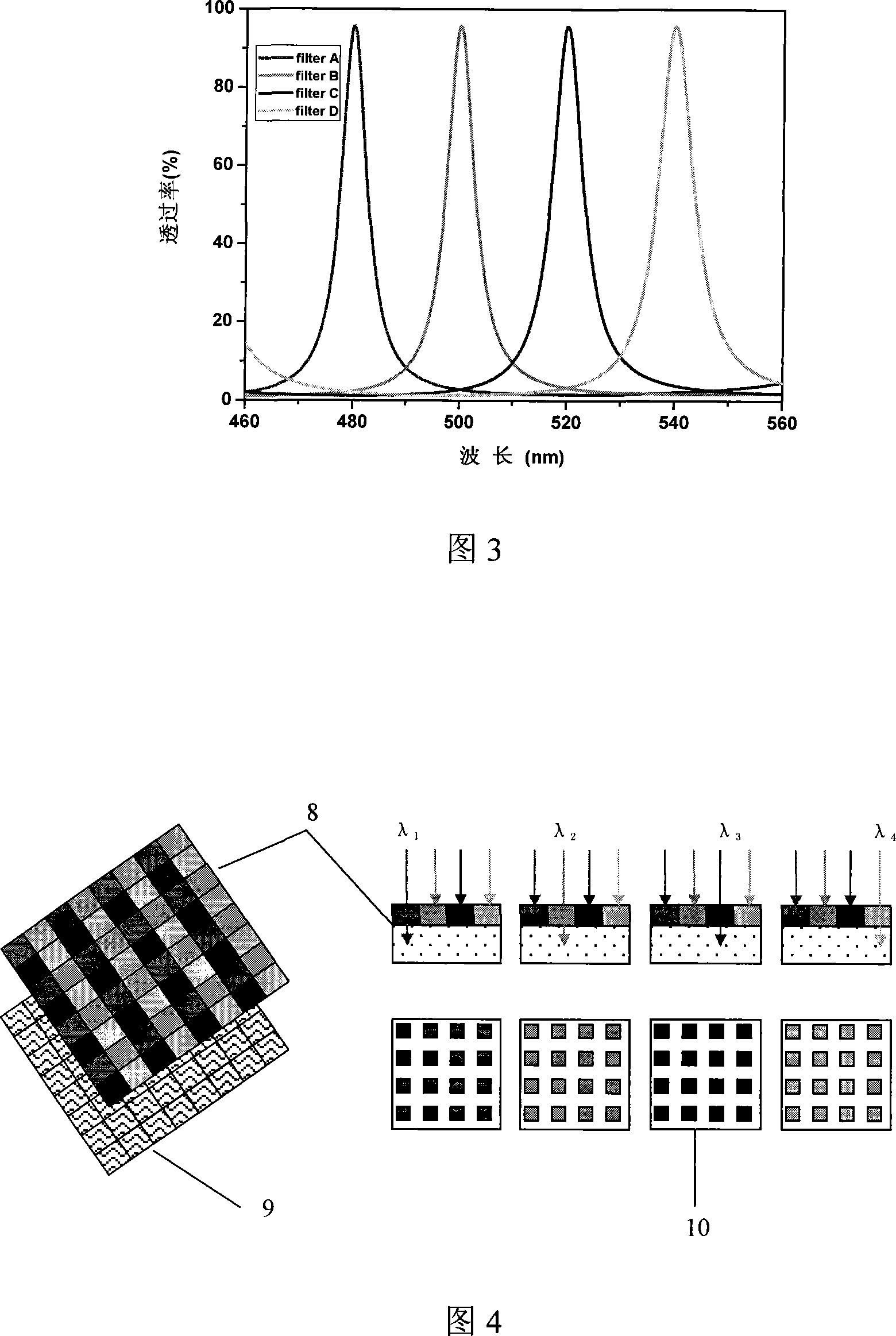

[0028] As shown in Figure 1, the micro-hyperspectral integrated filter is provided with an integrated filter and an incident medium 7 on the optical substrate 1, and the integrated filter is sequentially provided with first filters of equal length from left to right. 3. Second filter 4, third filter 5, fourth filter 6, first filter 3, second filter 4, third filter 5, fourth filter 6 They are respectively placed on the stepped etched self-stop layer 2, the first filter 3, the second filter 4, and the third filter 5 are provided with a stepped etched self-stop layer 2. The material for the etching self-stop layer 2 is magnesium fluoride.

[0029] Figure 2 is a schematic flow chart of the manufacturing process of the miniature hyperspectral integrated filter, including the following steps:

[0030] 1) Firstly use vacuum electron beam evaporation or sputtering to deposit a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com