Digital capacity measuring and repairing instrument for lead acid accumulator

A lead-acid battery, capacity testing technology, applied in the direction of lead-acid battery, secondary battery repair/maintenance, battery recycling, etc., can solve the problems of hindering electrolyte penetration, battery capacity reduction, blocking the hole of the plate, etc., to achieve Large economic benefits and social and environmental benefits, fast repair time, and the effect of definite life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

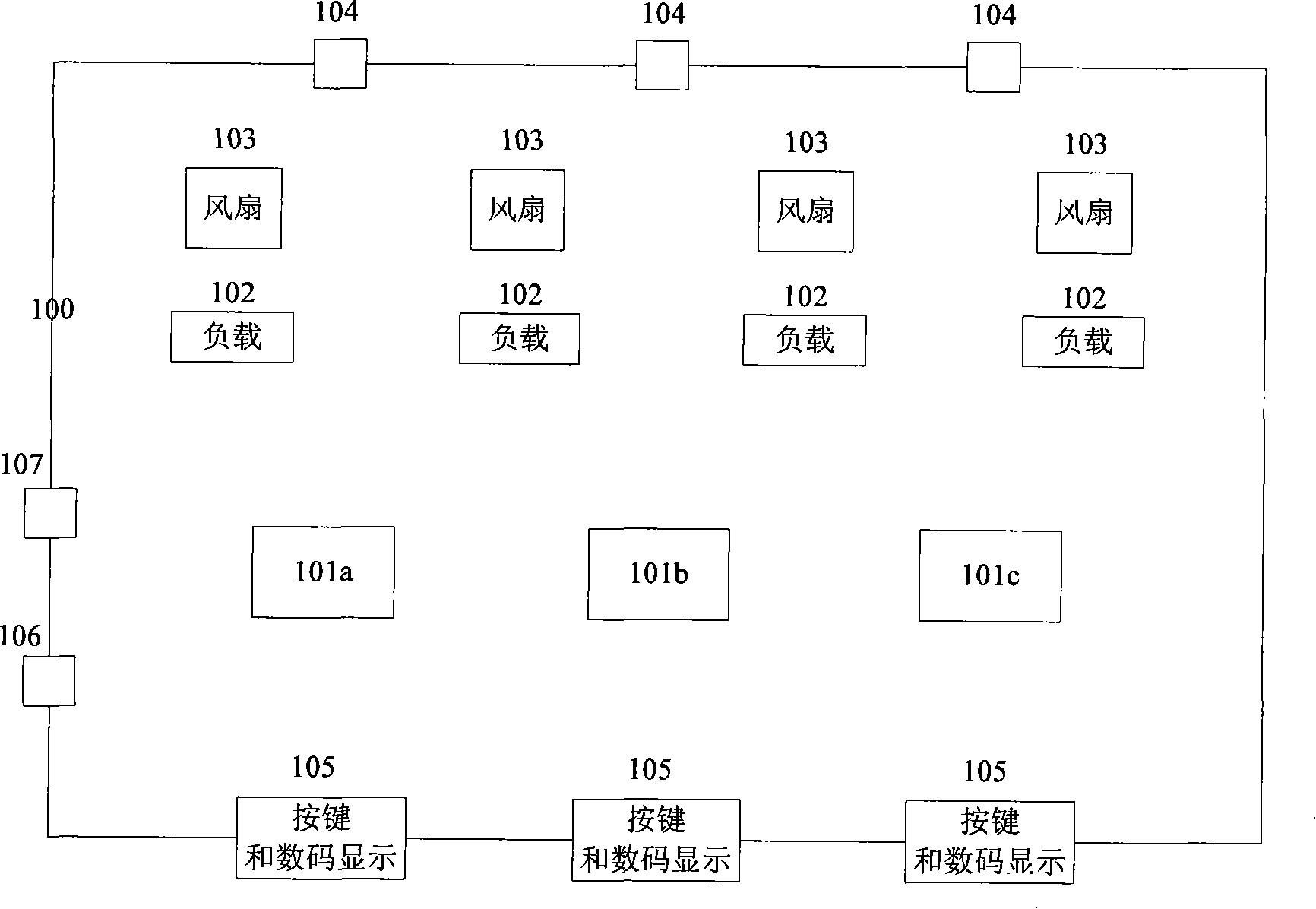

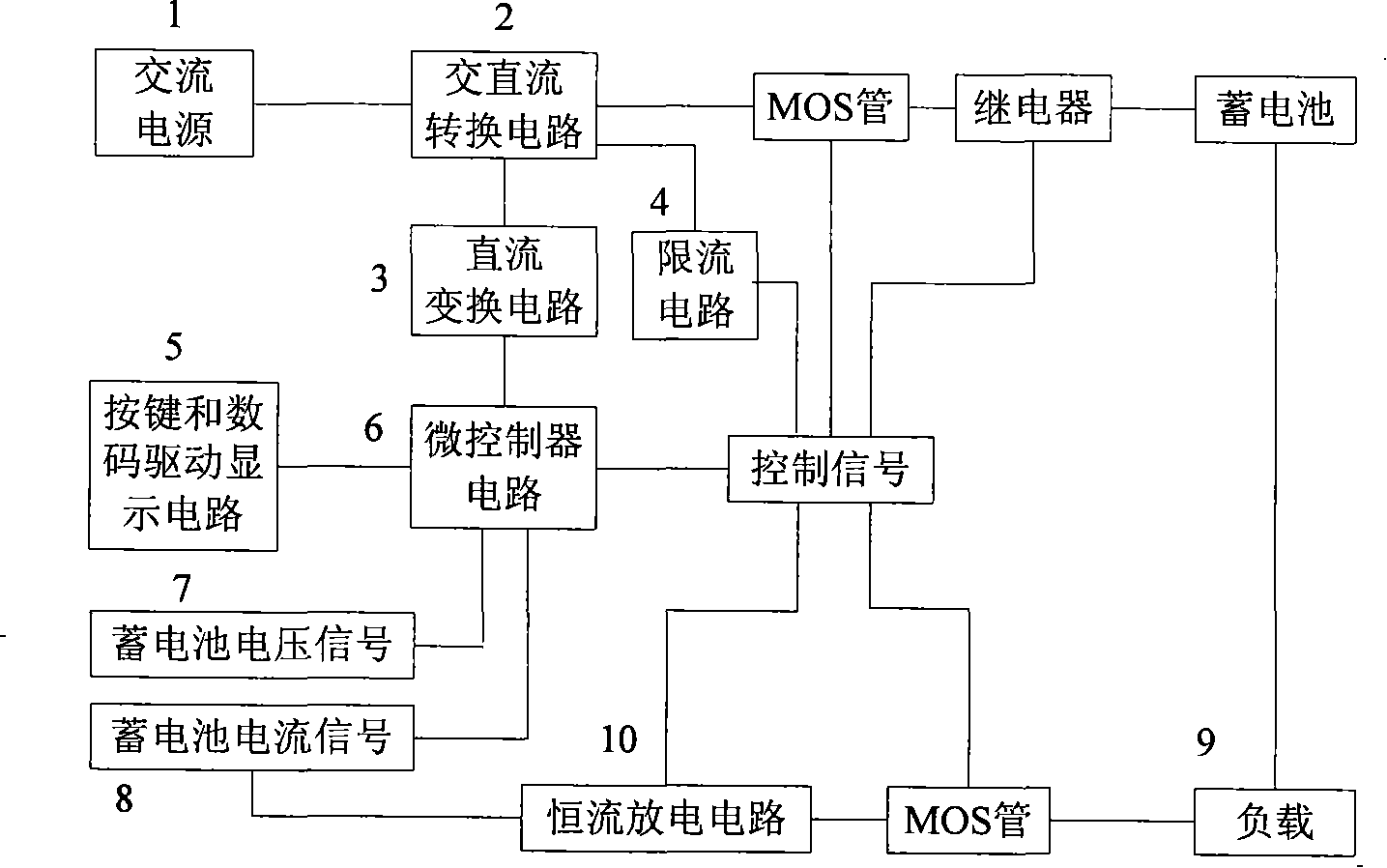

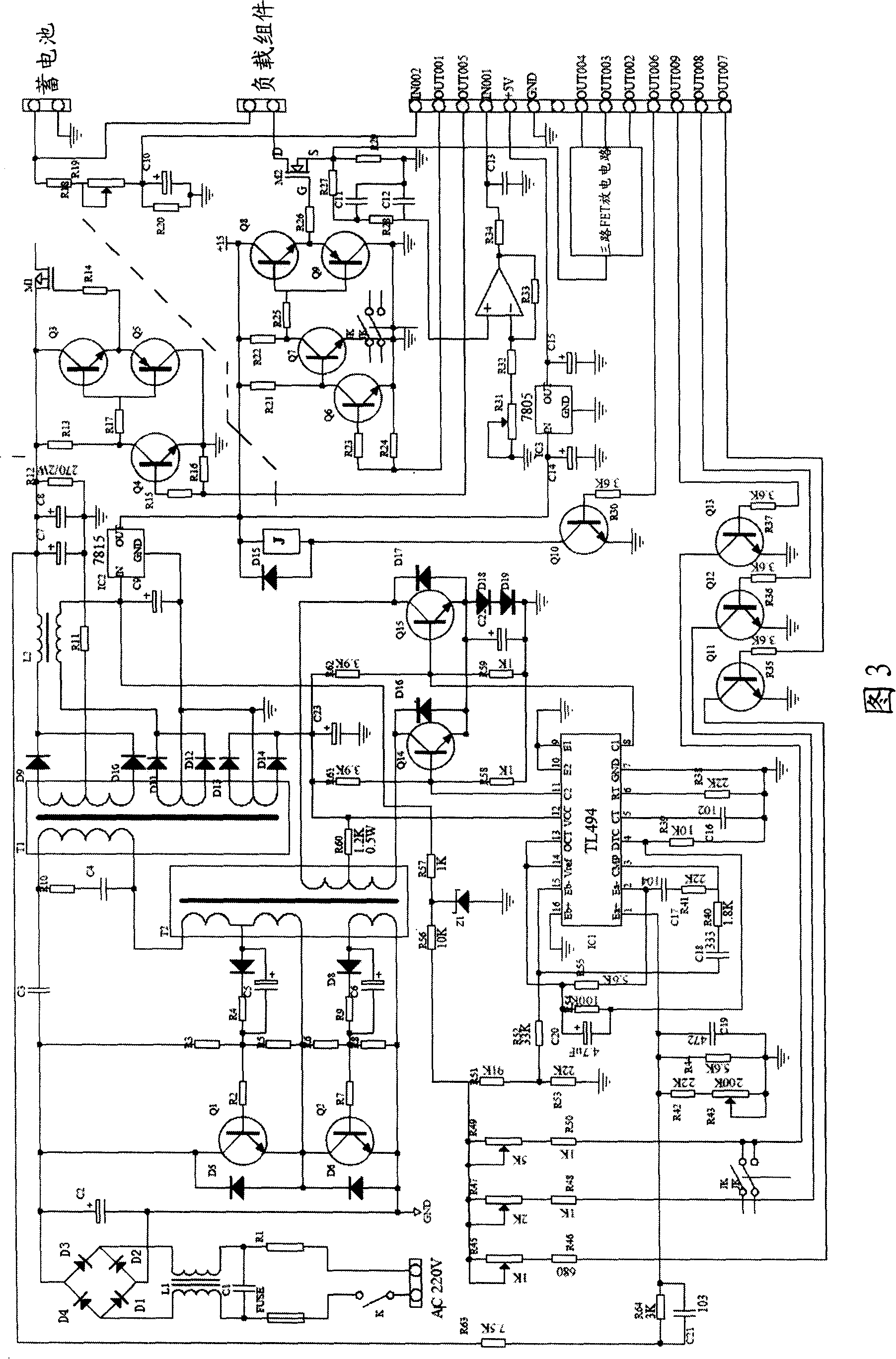

[0017] refer to figure 1 , the digital lead-acid battery capacity testing and repairing instrument includes a chassis 100, circuit boards 101a, 101b and 101c of the capacity testing and repairing circuit, four sets of loads 102, four cooling fans 103, three battery sockets 104, three digital display modules and buttons Module 105, 220v power socket 106, power switch 107. The 220v power supply is connected to the circuit board of the capacity test and repair circuit through the socket 106, and the AC-DC conversion circuit on the circuit board provides pulse voltage for the battery, and provides pulse voltage for the relay, microcontroller and digital The display module provides the supply voltage. The pole plate of the storage battery is connected with the circuit board of the capacity testing and repairing circuit through the storage battery socket 104 . When working in the capacity test mode, the storage battery is discharged through the load 102, and the fan 103 dissipates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com