Porous membrane, process for producing porous membrane, solid polymer electrolyte membrane, and fuel cell

A polymer material, porous membrane technology, applied in the field of functional membranes, can solve the problems of short-circuiting, pinholes, cross-leakage and other problems in electrodes, and achieve the improvement of current-voltage characteristics, enhance strength, and reduce fuel gas cross-leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] Examples of the present invention are shown below.

[0079] Each film of PEEK, PEI, and PSF manufactured by Sankyo Kasei Co., Ltd., PPSU manufactured by Solvay, and PPS manufactured by Toray Industries, Inc. was irradiated with laser light with a pulse width of 150 fs and an output power of 0.03 W at the focal position 0.01 seconds to 1.0 seconds to form a porous membrane with through-holes 5 to 30 microns in diameter.

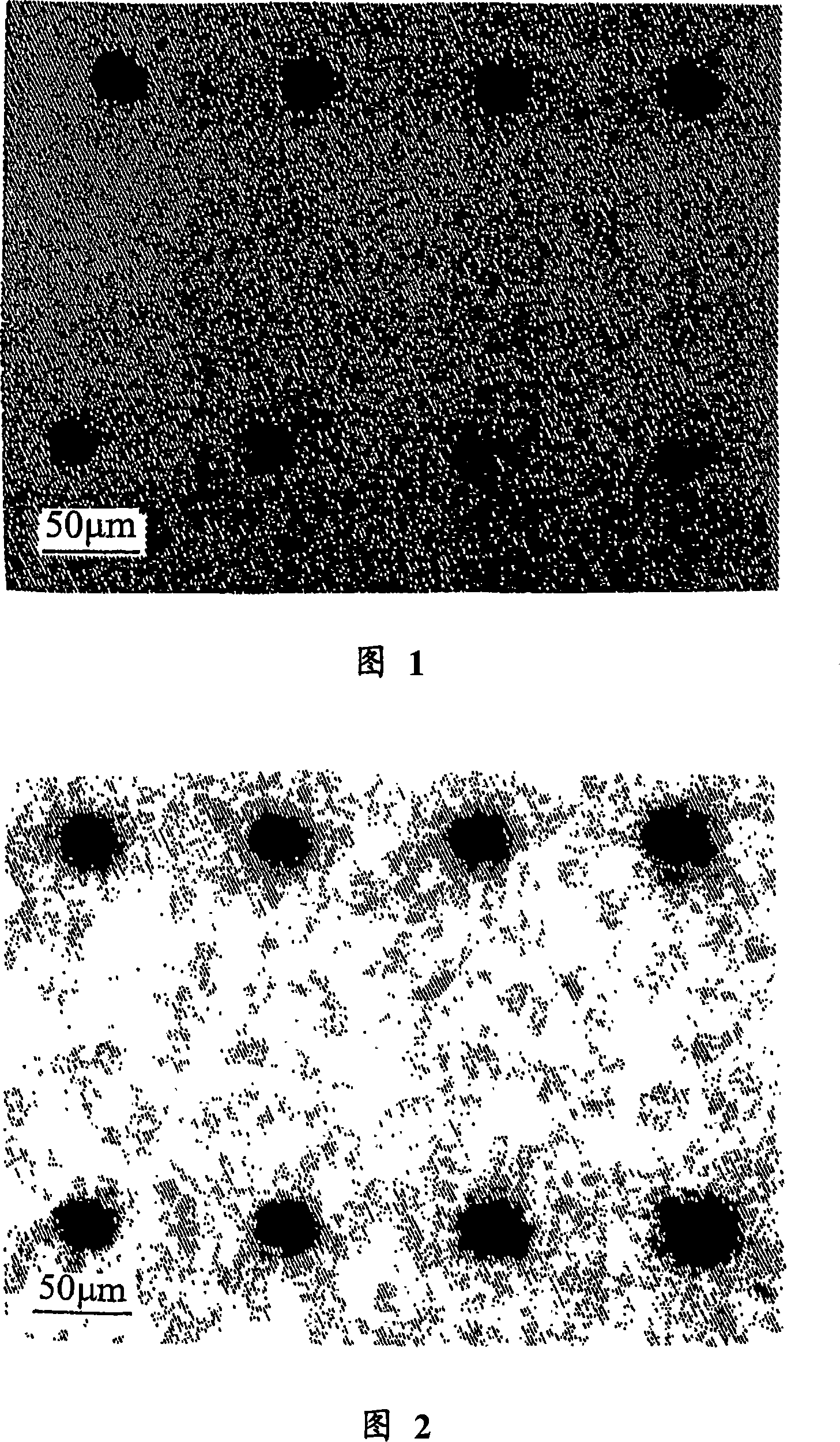

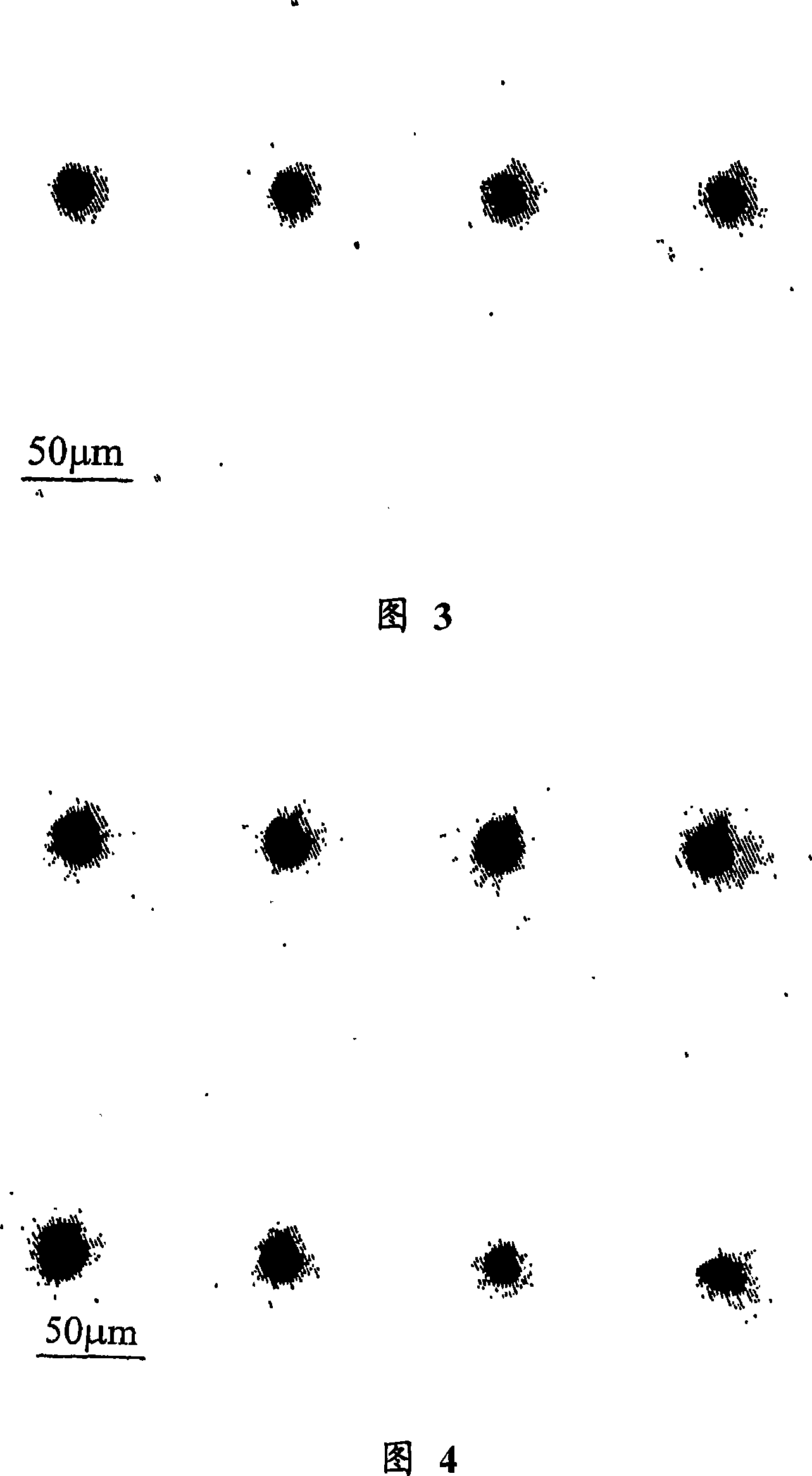

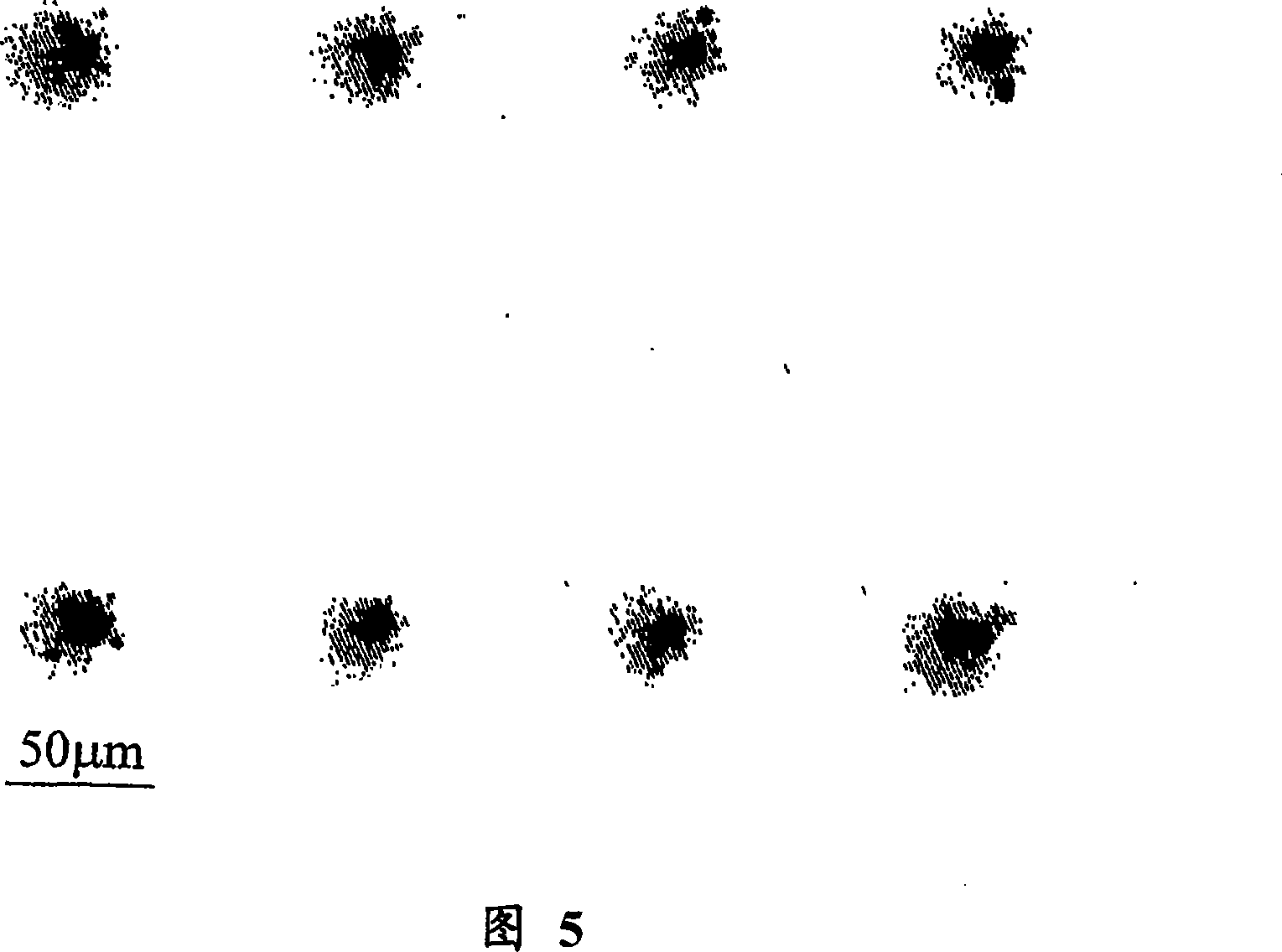

[0080] 1 to 5 show examples of laser microscopic observation results on the front and back sides of each porous film, respectively. Figure 1 shows the laser irradiation surface of PEEK (55 micron film thickness) obtained in the examples, where the upper column represents the irradiation time from left to right from 0.01 second to 0.04 second (in increments of 0.01 second), and the lower column from left to right Indicates the focal length from 0 mm to 0.15 mm (in increments of 0.05 mm). Fig. 2 shows the laser irradiation surface of PEI (50 mm film thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com