Continuous rheological extending forming method for preparing Al alloy tube

An aluminum alloy tube and extended technology, applied in metal rolling and other directions, can solve the problems of immature industrial application and no continuous forming research, and achieve the effects of superior structure and performance, avoiding uneven forming and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

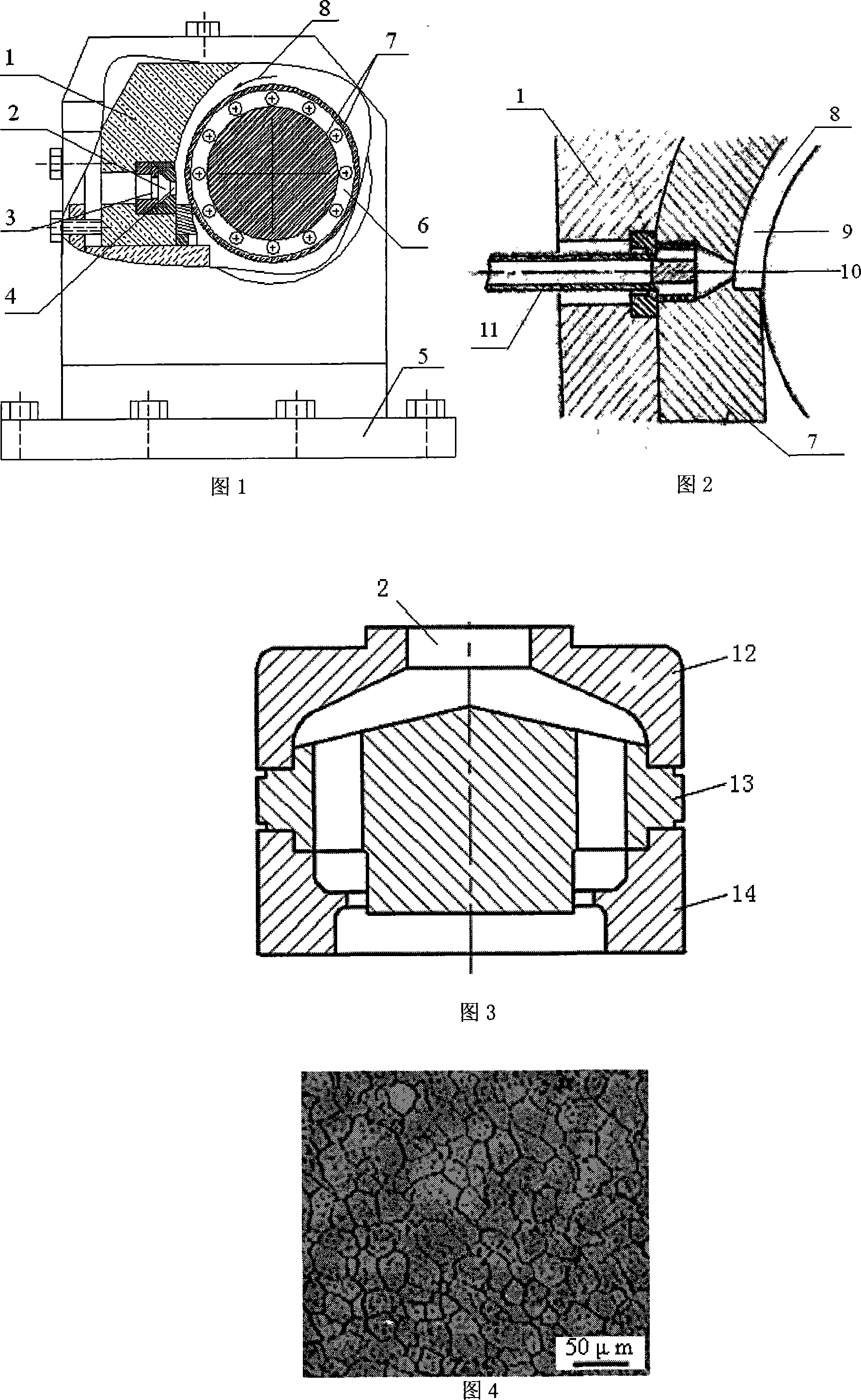

[0028] Embodiment 1: The continuous rheological expansion forming machine adopted in the present invention (the declared patent application number is 200720185231X, and the application date is 2007-12-27), as shown in Fig. 1 and Fig. 3 . Its working principle for preparing aluminum alloy pipes is shown in FIG. 2 . The device is mainly composed of a water-cooled rotating roll composed of a cooling chamber and a roll sleeve, an extrusion molding die, a back pressure block, a fixed shoe seat installed on the frame, and a discharge plate. The alloy melt is poured at the top entrance of the roller shoe cavity, and the alloy melt is dragged into the roller shoe cavity by the friction force exerted by the rotating work roll. In the roller shoe cavity, the alloy melt is gradually cooled and rotated at the same time The work rolls are sheared and stirred to form aluminum alloy pipes. The specific steps are as follows:

[0029] (1) With a purity of 99.99wt% industrial aluminum, Al-Si m...

Embodiment 2

[0035] Embodiment 2: the device of this example is identical with embodiment 1, adopts the technology that this device produces 6201 aluminum alloy pipes, comprises the steps:

[0036] (1) With a purity of 99.99wt% industrial aluminum, Al-Si master alloy and a purity of 99.99wt% industrial magnesium as raw materials for the alloy, the preparation of 6201 alloy, its main chemical composition (mass fraction) is Mg0.8%, Si0. 7%, the sum of impurities = 0.1%, the remainder of Al;

[0037] (2) Preheat the melting furnace to 700°C, add pure aluminum ingots step by step for heating and melting, after the melting temperature reaches 760°C, add Al-Si master alloy, and after the melt cools down to 720°C, put the pretreated Industrial pure magnesium is pressed into the melt;

[0038] (3) After the metal is melted, use the JWK-702 precision temperature control cabinet to control the temperature of the melt, and when the temperature reaches 740°C, refine with 0.3% hexachloroethane;

[00...

Embodiment 3

[0042] Embodiment 3: the device of this example is identical with embodiment 1, adopts the technology that this device produces 6201 aluminum alloy pipes, carries out as follows:

[0043] (1) be 99.99wt% industrial pure aluminum with purity, Al-Si master alloy and purity be 99.99wt% industrial pure magnesium as the raw material of alloy, prepare 6201 alloy, its main chemical composition (mass fraction) is Mg0.8%, Si0.7%, sum of impurities = 0.1%, Al balance;

[0044] (2) Preheat the melting furnace to 700°C, add pure aluminum ingots step by step for heating and melting, after the melting temperature reaches 760°C, add Al-Si master alloy, and after the melt cools down to 720°C, put the pretreated Industrial pure magnesium is pressed into the melt;

[0045] (3) After the metal is melted, use the JWK-702 precision temperature control cabinet to control the temperature of the melt, and when the temperature reaches 740°C, refine with 0.5% hexachloroethane;

[0046] (4) After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com