Electric discharge machining apparatus

A processing device, electric spark technology, applied in electric processing equipment, accessories, metal processing equipment, etc., can solve the problems of increased discharge energy, difficulty in high frequency voltage, high cost, etc., to reduce discharge energy, improve surface The effect of finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

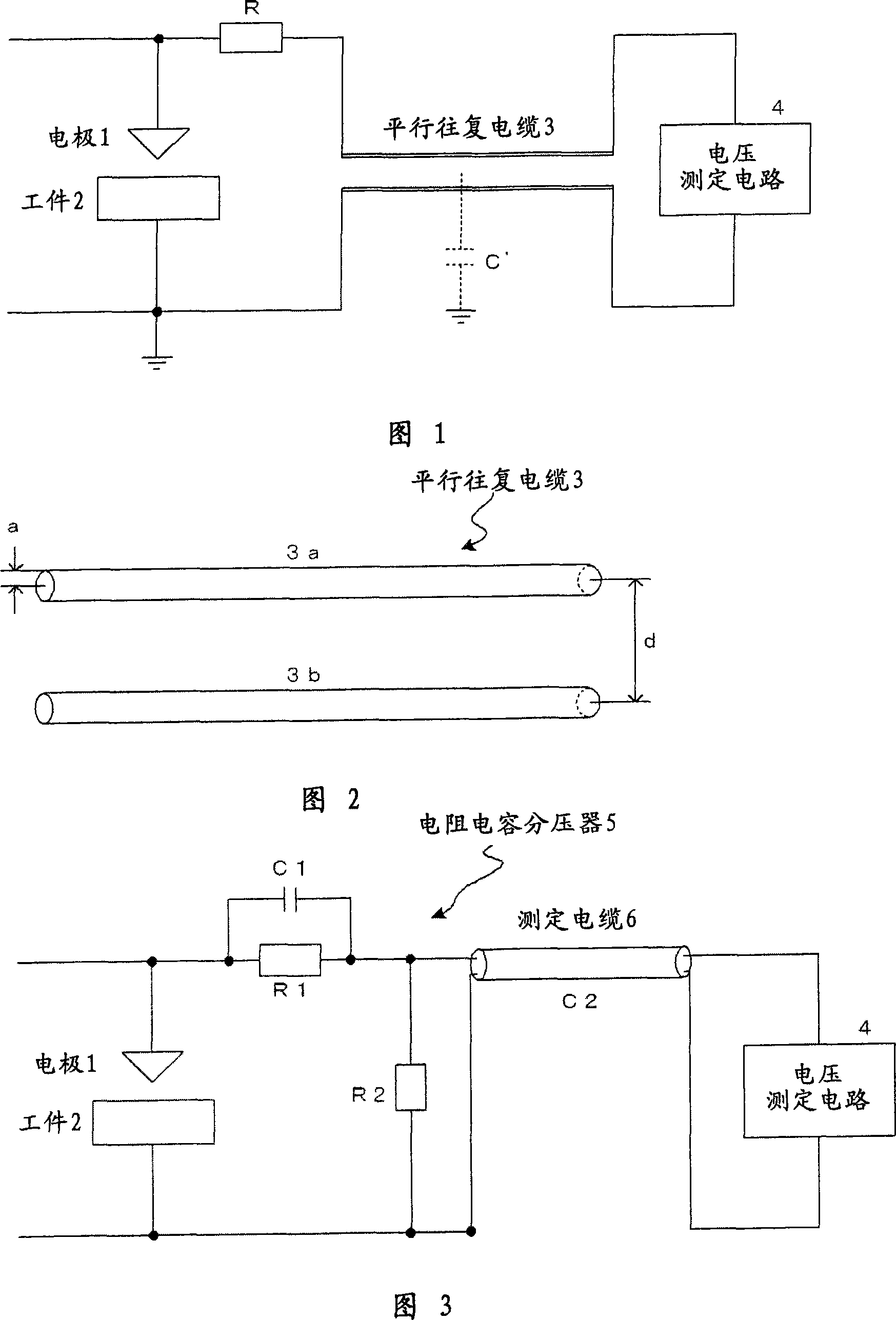

[0028] Fig. 1 is a schematic diagram of main parts of a first embodiment of the present invention. This first embodiment is characterized in that a voltage measurement circuit for measuring the inter-electrode voltage between the electrode and the workpiece is connected using a parallel reciprocating cable having a wide distance between lines, such as a feeder line for a TV antenna.

[0029] In FIG. 1 , reference numeral 1 is an electrode, and reference numeral 2 is a workpiece of a workpiece. A voltage is applied between the electrode 1 and the workpiece 2 (between the electrodes) by a machining power source (not shown). In addition, reference numeral 4 is a voltage measurement circuit for measuring the inter-electrode voltage between the electrode 1 and the workpiece 2, and the discharge state is monitored based on the inter-electrode voltage measured by the voltage measurement circuit 4, and the electrode 1 with respect to the workpiece 2 is monitored. Control of relative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com