Impulse oscillation pre-magnetization device

A technology of pulse vibration and pre-magnetizer, which is applied to magnetic objects, electrical components, circuits, etc., can solve the problems of loss of magnetism of permanent magnet materials, small magnetic field of permanent magnet magnetization equipment, and failure to achieve magnetization effect, so as to prolong the service life, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

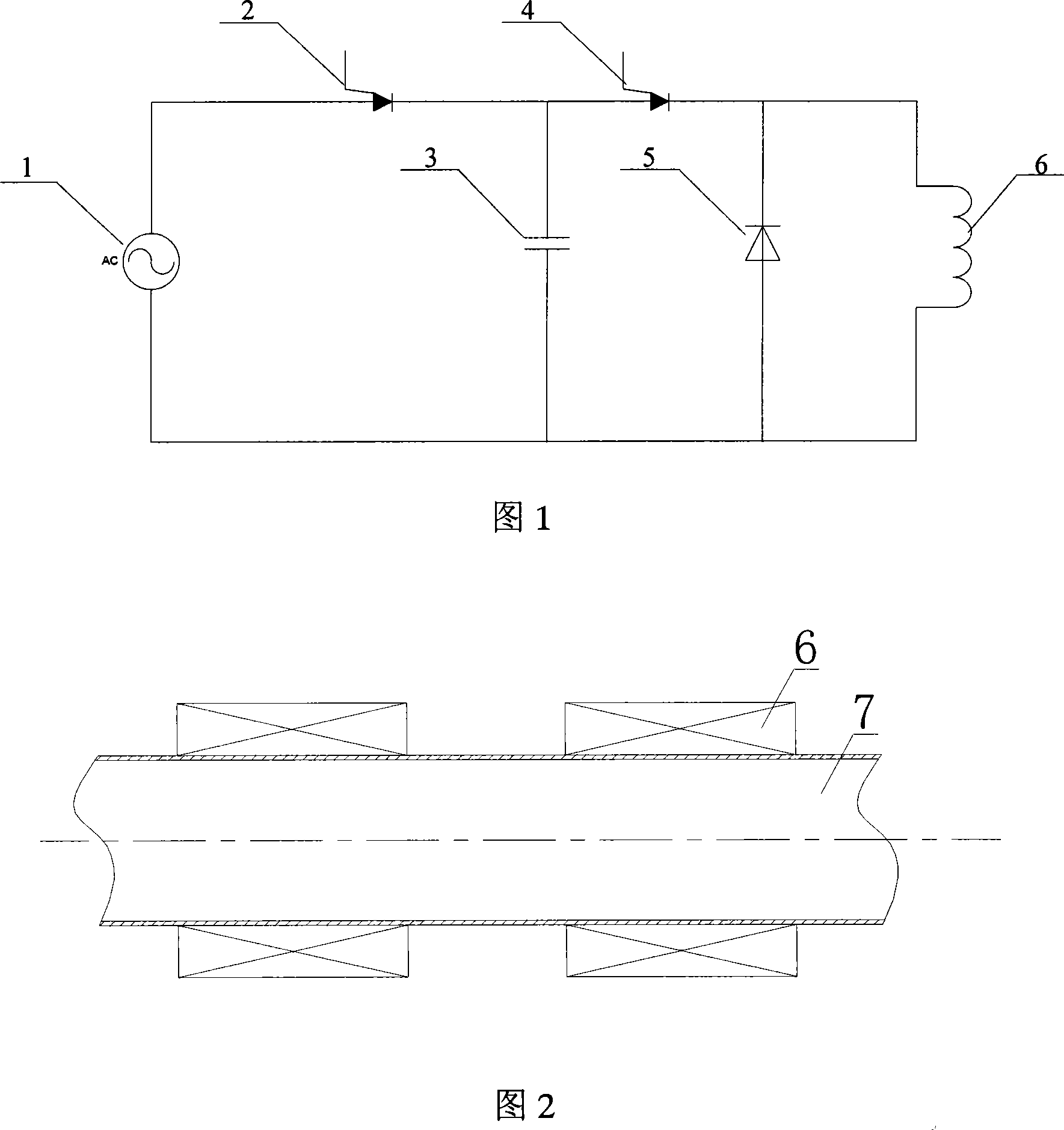

[0016] The present invention will be described in detail below with reference to the accompanying drawings.

[0017] As shown in the figure, the present invention includes a microprocessor control board, an iron concentration sensor and a solenoid coil. The microprocessor control board uses a single-chip microcomputer as the core to design a peripheral circuit, mainly including a thyristor pulse trigger circuit, an iron concentration Oscillating circuit, sensor, control keyboard and display circuit are composed. Use circuit drawing software to design the schematic diagram, and then make it into a printed circuit board (PCB). Install each chip, pulse transformer, etc. on the PCB; the power capacitor is charged in 3 hours and discharged to the magnetic field coil in a hour.

[0018] For the iron concentration sensor, a coil is wound on a round pipe with a flange to form an iron concentration sensor with an inductance value of 0.96mH and connected to the microprocessor control b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inductance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com