Metal wall tile with honeycomb structure

A technology of honeycomb structure and wall tiles, which is applied in building construction, covering/lining, construction, etc., can solve the problems of high load-bearing capacity requirements of thermal insulation materials, self-heavy porcelain exterior wall tiles, and restrictions on the use of high-rise buildings. Achieves weight reduction, increased stiffness, and increased fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

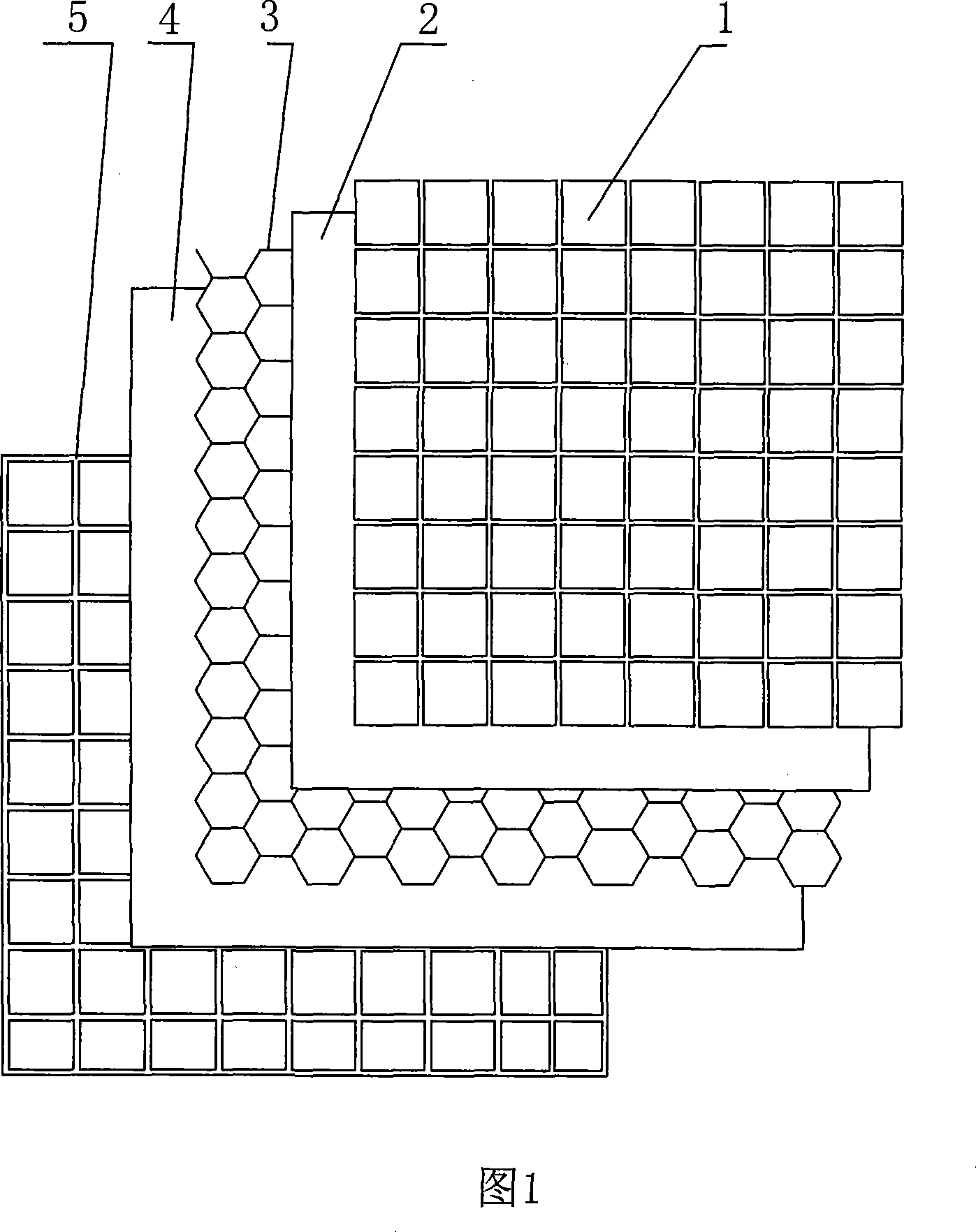

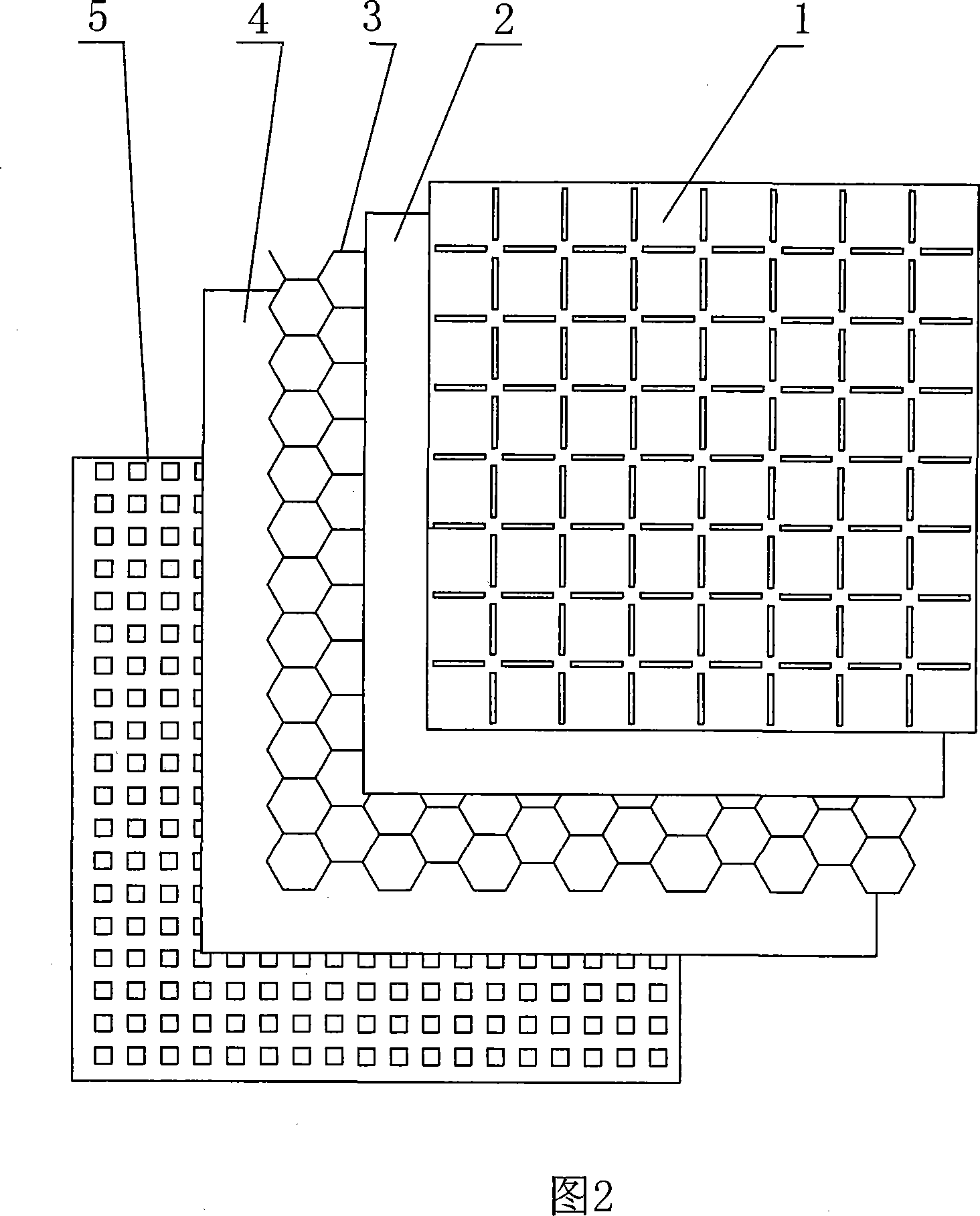

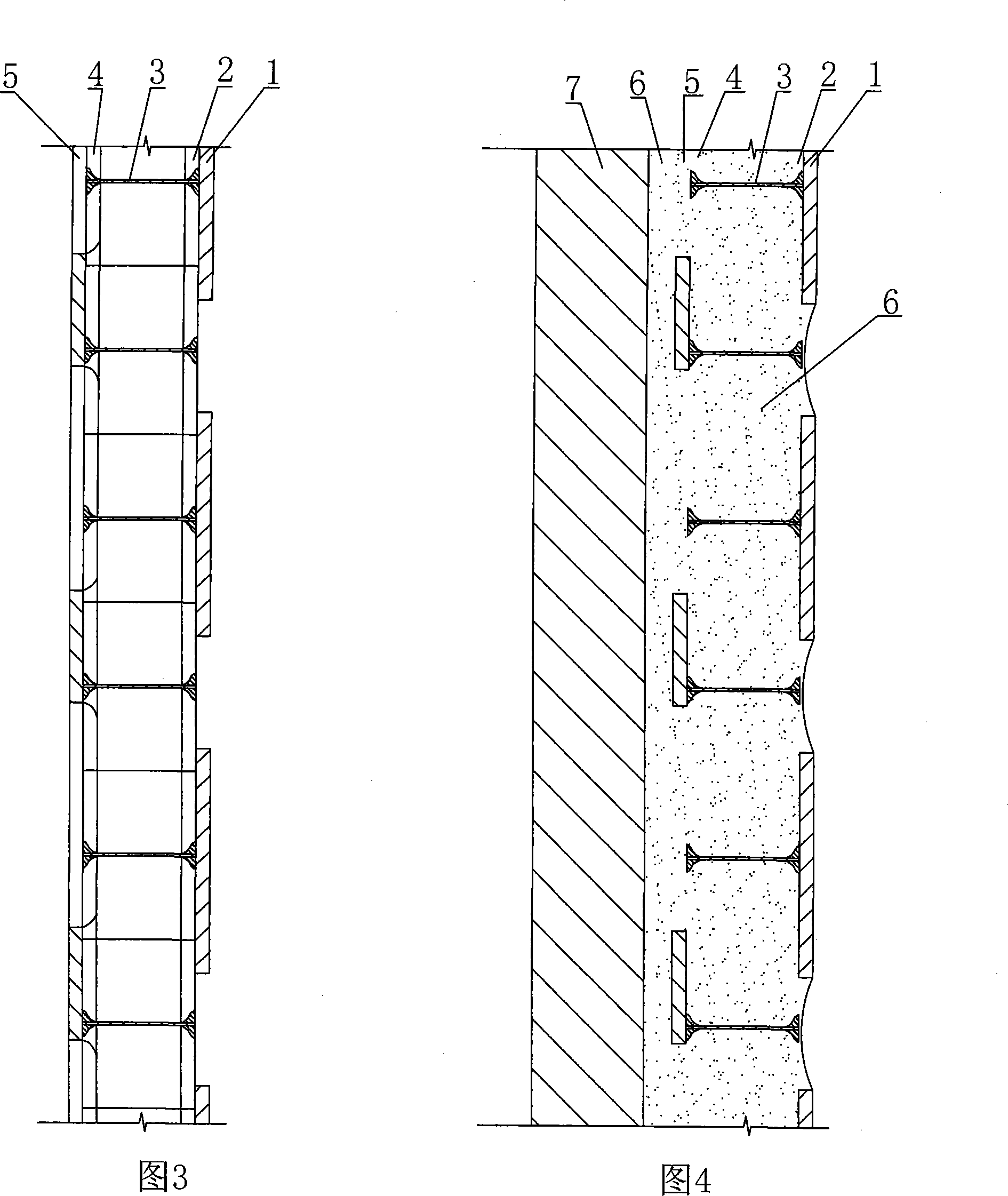

[0016] As shown in FIGS. 1, 2 and 3, the metal wall tiles with honeycomb structure are composed of a panel layer 1, a first glue layer 2, an aluminum honeycomb core layer 3, a second glue layer 4 and a substrate layer 5. Figure 1 is a schematic diagram of the first specific structure of the present invention after layering. The panel layer 1 is composed of several small metal plates separated by a gap. This structure has good air permeability, and the panel layer 1 can Various materials such as aluminum plate, stainless steel plate, color steel plate, galvanized plate, copper plate or original zinc plate are used to make the tiles have a long service life and a beautiful appearance. The base plate layer 5 is a galvanized metal sheet, which makes the tile have a longer service life. The metal sheet is stamped into a larger hollow shape in advance, and the weight is lighter. Due to its special shape and structure, it is easy to combine with the cement slurry. The stability is better...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com