Round tube type micro-mortise heat tube using carbon nano-tube suspending liquid as working medium

A technology of carbon nanotubes and suspensions, which is applied in the field of devices in the field of nanotechnology, can solve problems such as not being retrieved, and achieve the effects of increasing maximum power, reducing total thermal resistance, and improving heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

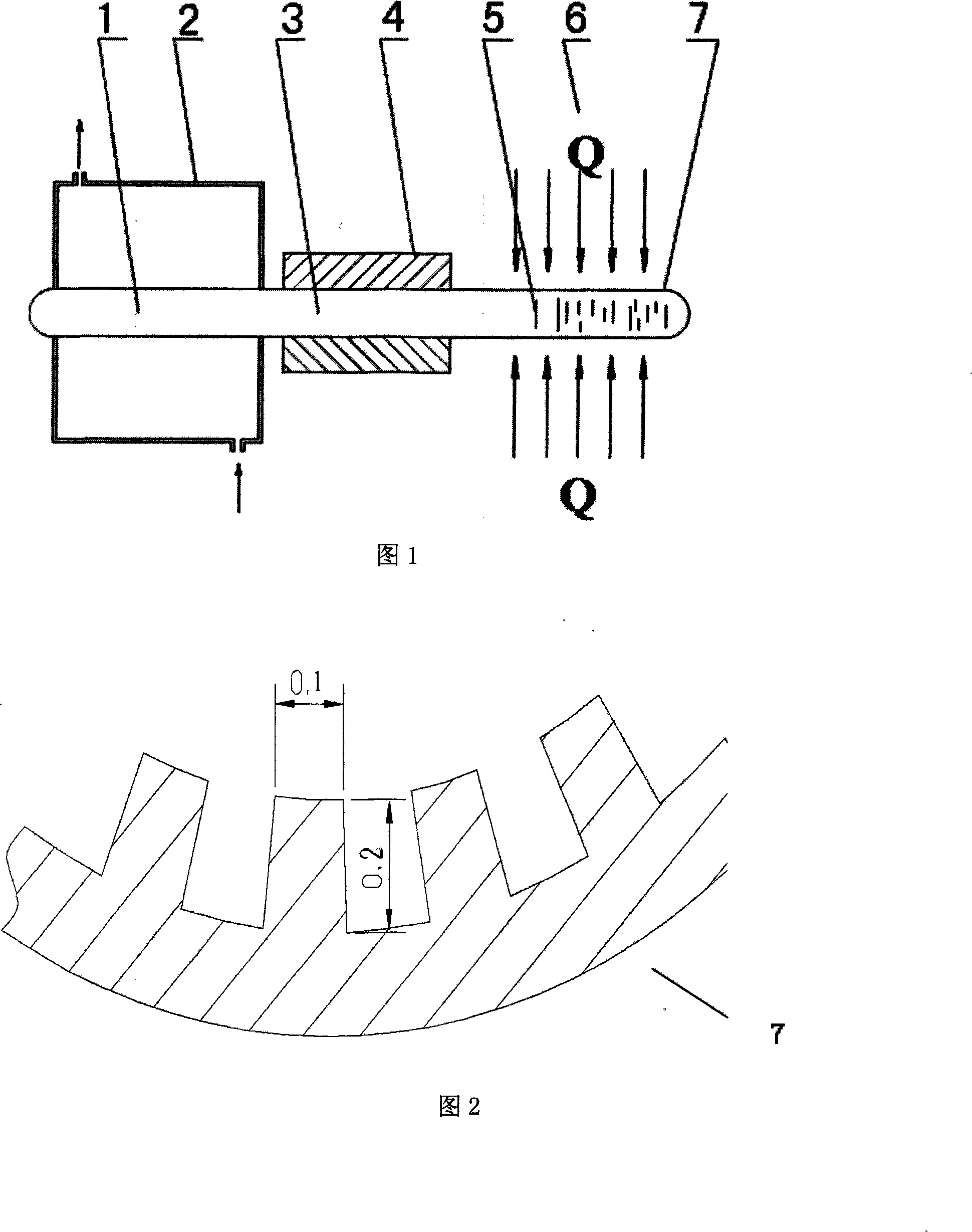

[0019] As shown in FIG. 1 , in this embodiment, the entire circular tube-type micro-groove heat pipe is formed by processing the condensation section 1 , the heat insulation section 3 , and the evaporation section 7 with copper tubes.

[0020] The outer diameter of the copper tube is 8mm, the wall thickness is 0.6mm, the channel width is 0.25mm, the rib width is 0.1mm, the channel depth is 0.2mm, the number of channels is 60, the total length is 350mm, the length of the heating section is 100mm, and the length of the insulation section is 100mm. The condensation secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com