Integrated performance test method for vaporization cooling in various heat exchange models and modes

A technology of evaporative cooling and testing method, applied in the field of integrated testing, can solve problems such as poor versatility, and achieve the effects of ingenious structure, high sensitivity and strong comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawings and examples.

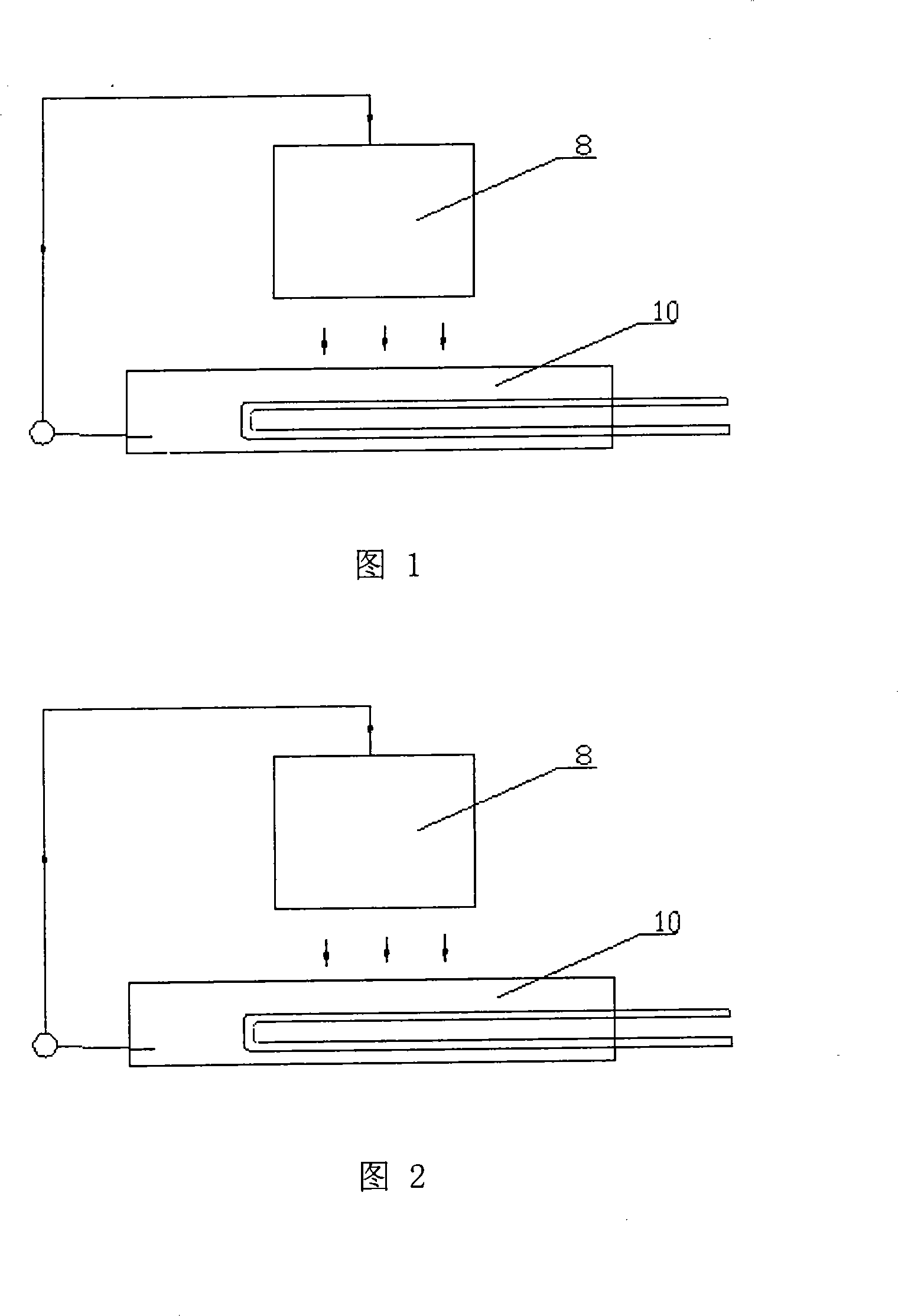

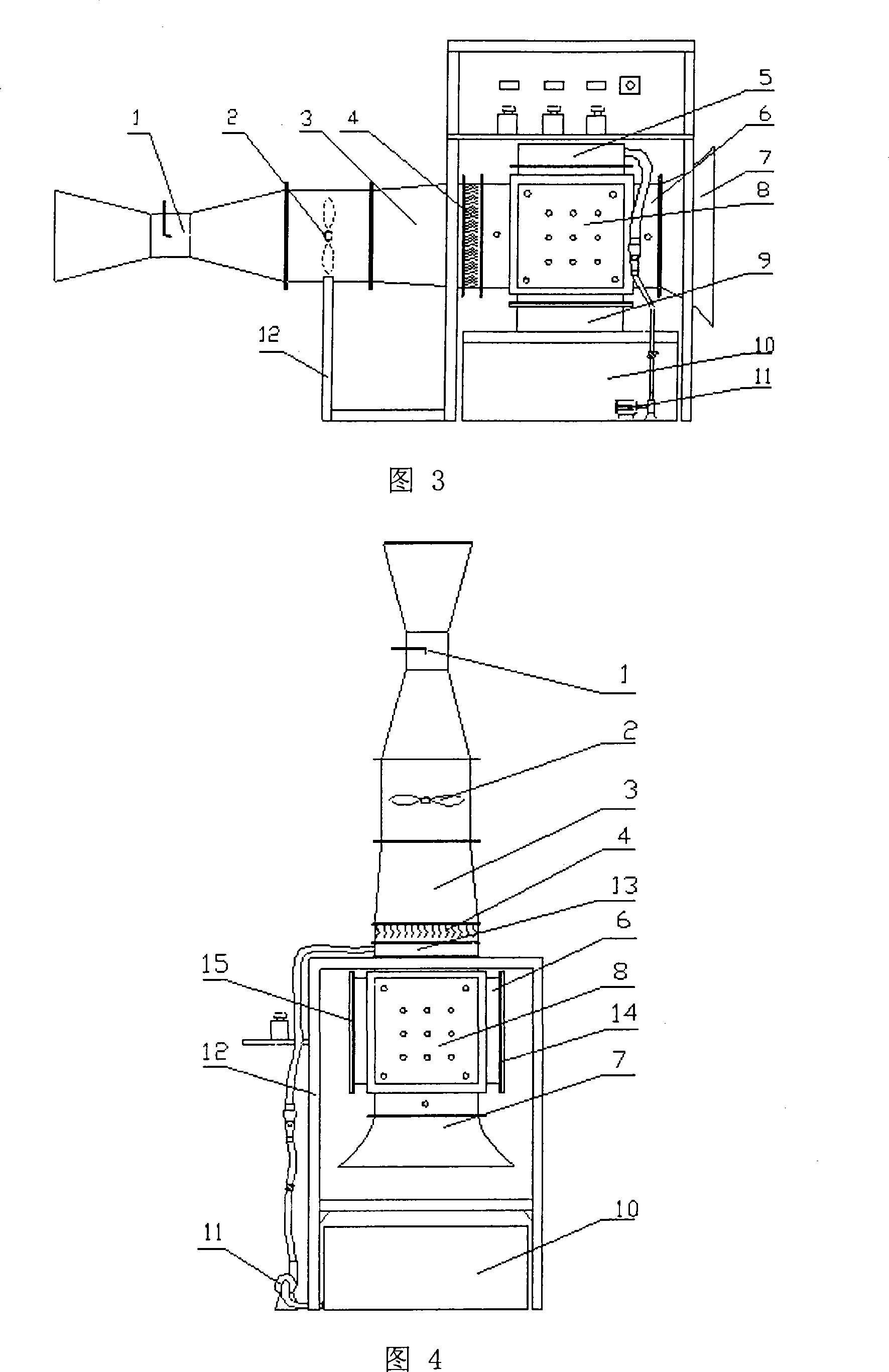

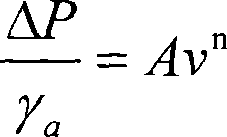

[0038]The integrated performance test method for evaporative cooling in different heat transfer models and modes of the present invention is based on a multifunctional test bench for performance testing of evaporative cooling heat transfer modules. The test bench includes a wind system, a water system and a test system, mainly composed of a water collection tank 10, a water collection tank cover 9, a water pump 11, an air volume test 1, a fan 2, a circular transition section 3, a water receiver section 4, and a water spraying pipe network Section 13, tested heat exchange module section 6, tested heat exchange module 8, air inlet section 7, water distribution pool 5, side covers 14, 15 of two tested heat exchange module sections and bracket 12. The dry and wet bulb temperature of the air is tested by a mechanical ventilation dry and wet bulb thermometer; the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com