Atomizing corona plasma flue gas purifying equipment

A plasma and flue gas purification technology, used in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unable to prevent secondary pollution of sewage, unable to work stably for a long time, and increase maintenance-free time, Low maintenance cost and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention is not limited to the embodiments set forth herein. Rather, these embodiments are disclosed so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

[0026] The purpose of the following examples is suitable for illustrating the present invention, and the instruments used, detection methods, etc. are not intended to limit the scope of the present invention.

[0027] The atomization corona plasma flue gas purification technology is to maintain the electric atomization wet state with a small amount of water in the discharge electrode, and the atomized water droplets impact the collecting plate and form a thin and uniform water film on the surface of the plate. After the dripping water is separated from the oily dirt, the pump returns the electrodes for recycling.

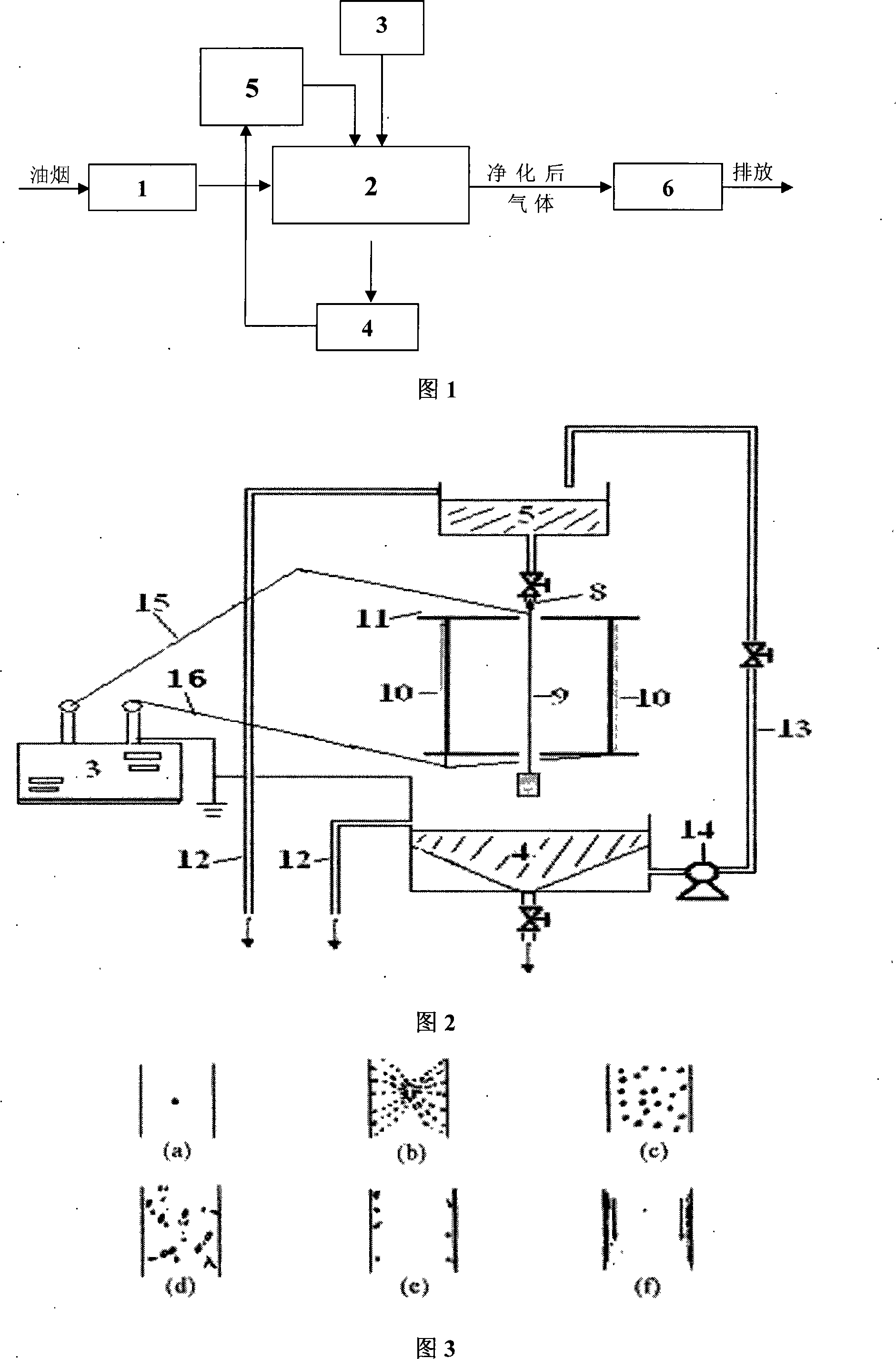

[0028] In accompanying drawing 1, when work starts, high voltage power supply 3, induced draft fan 6 are opened. Form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com