Electric heavy type traction special-purpose automobile

An electric, heavy-duty technology, applied in electric vehicles, electric traction, vehicle energy storage, etc., can solve the problems of inability to work continuously, long charging time, difficult to adapt to heavy load conditions, etc., and achieve the effect of improving the working environment and reducing noise pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

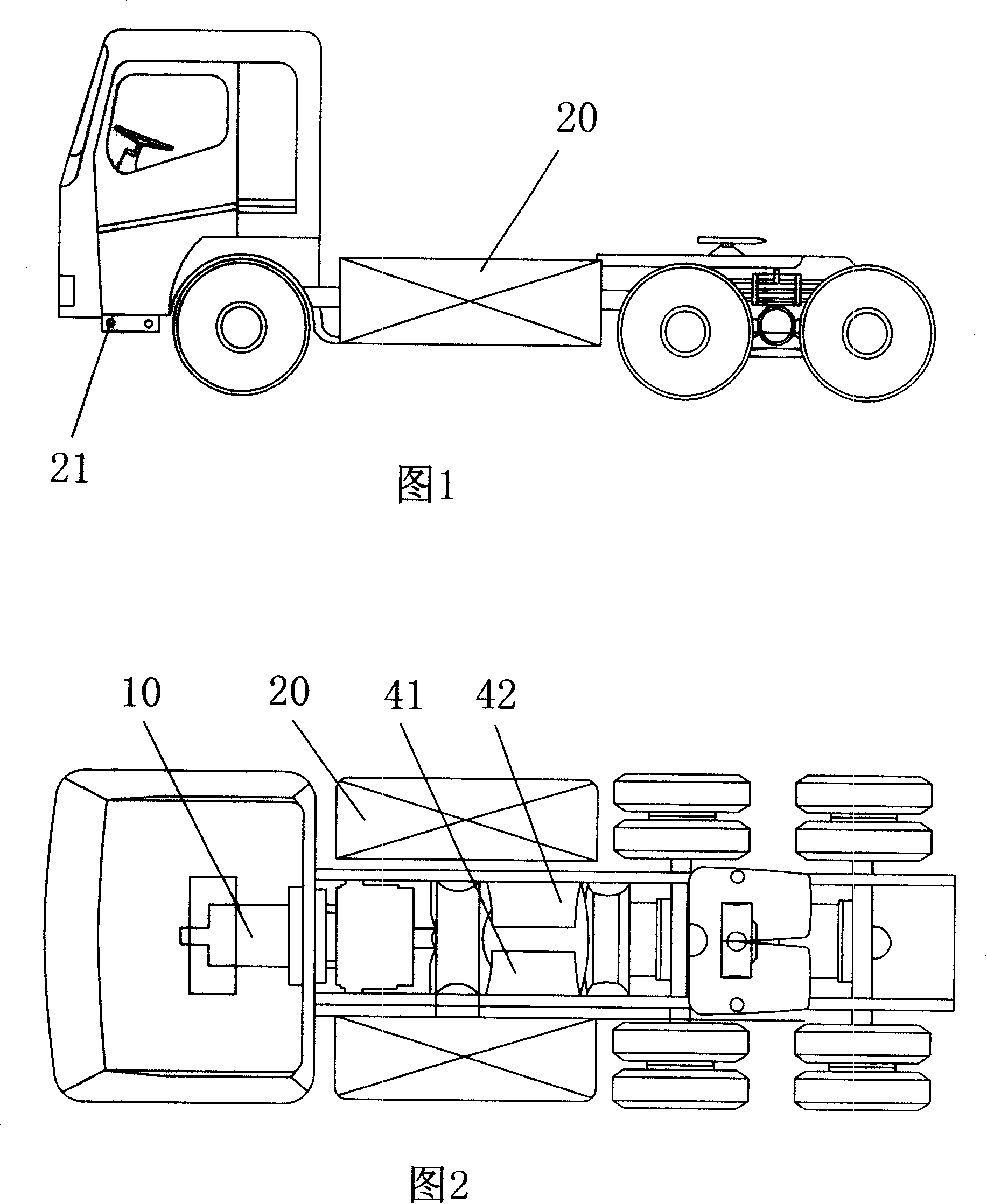

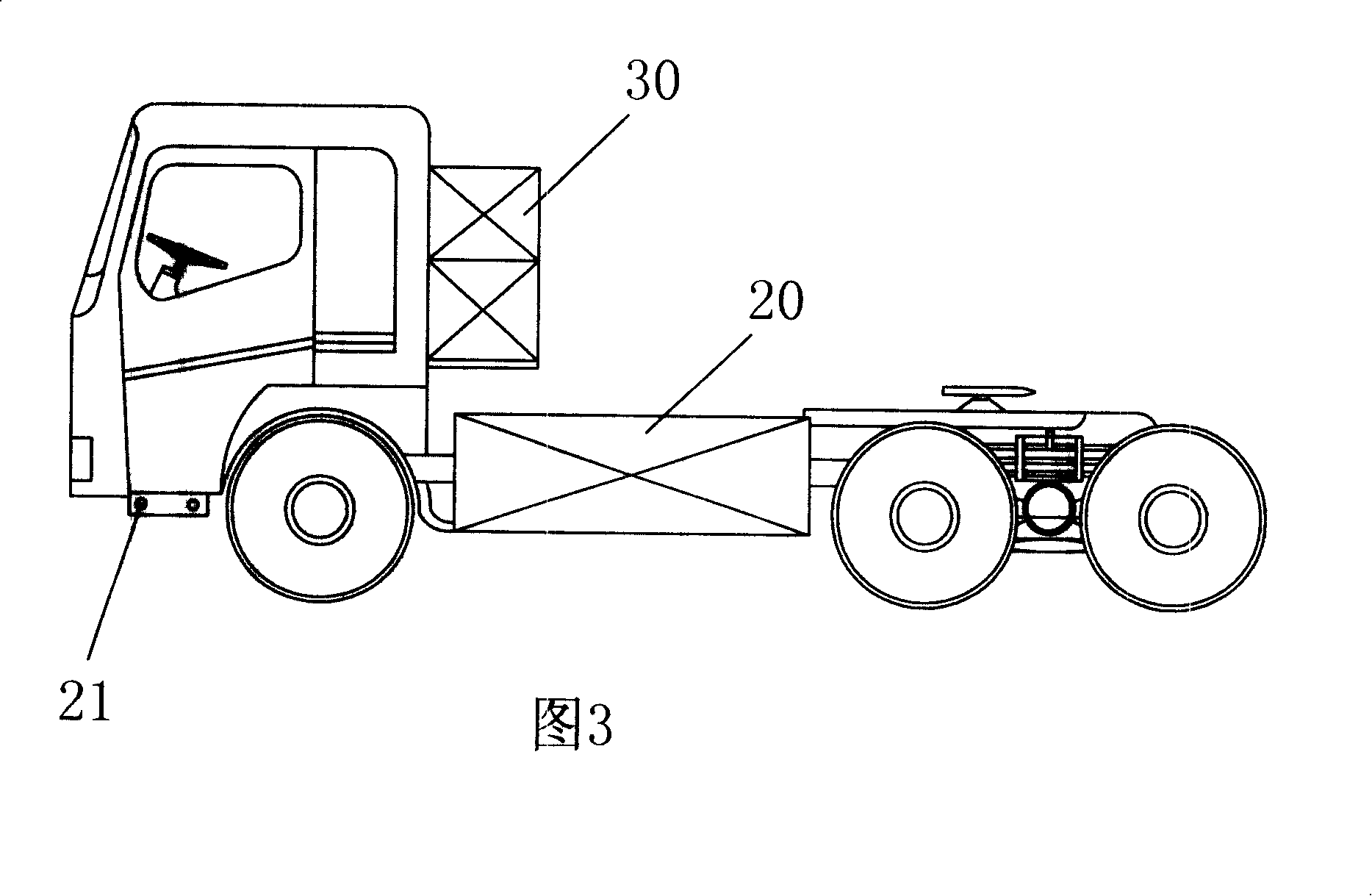

[0024] The electric heavy-duty traction special vehicle provided by the invention is refitted on the basis of the existing domestic tractor. As shown in Figure 1, the modification steps include:

[0025] 1. Remove the diesel engine, water tank, fuel tank, intake and exhaust pipes of the original car, and replace them with the electric motor 10 and the controller;

[0026] 2. Keep the original car gearbox and clutch, the output shaft of the motor 10 is connected to the clutch; and a clutch housing is configured, the front end of the clutch housing is connected to the motor housing, and the rear end is connected to the gearbox housing;

[0027] 3. A special power supply 20 is installed between the front and rear wheels and on the outside of the frame, and the two special power supplies 20 are arranged symmetrically;

[0028] 4. Install the electric brake air pump 41 and the power steering pump 42 .

[0029] Of course, in order to meet the needs of special working conditions, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com