Three-layer type sleeping cabin

A technology of sleeping cabin and bottom layer, which is applied in the direction of living cabins, sleeper appliances, transport passenger cars, etc. It can solve the problems of complex movements, high difficulty in moving the bed, and inability to provide comfortable sitting environment for passengers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

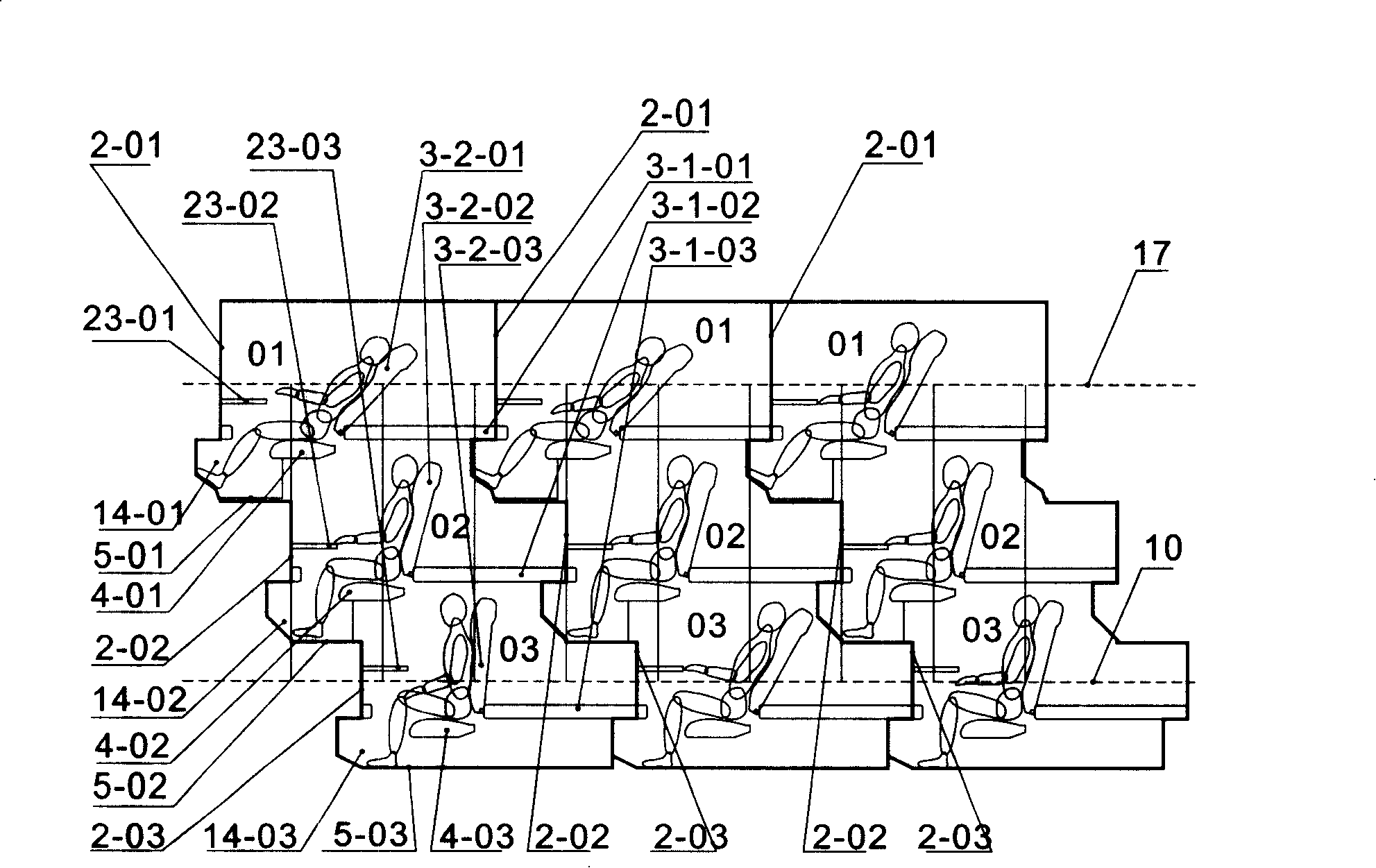

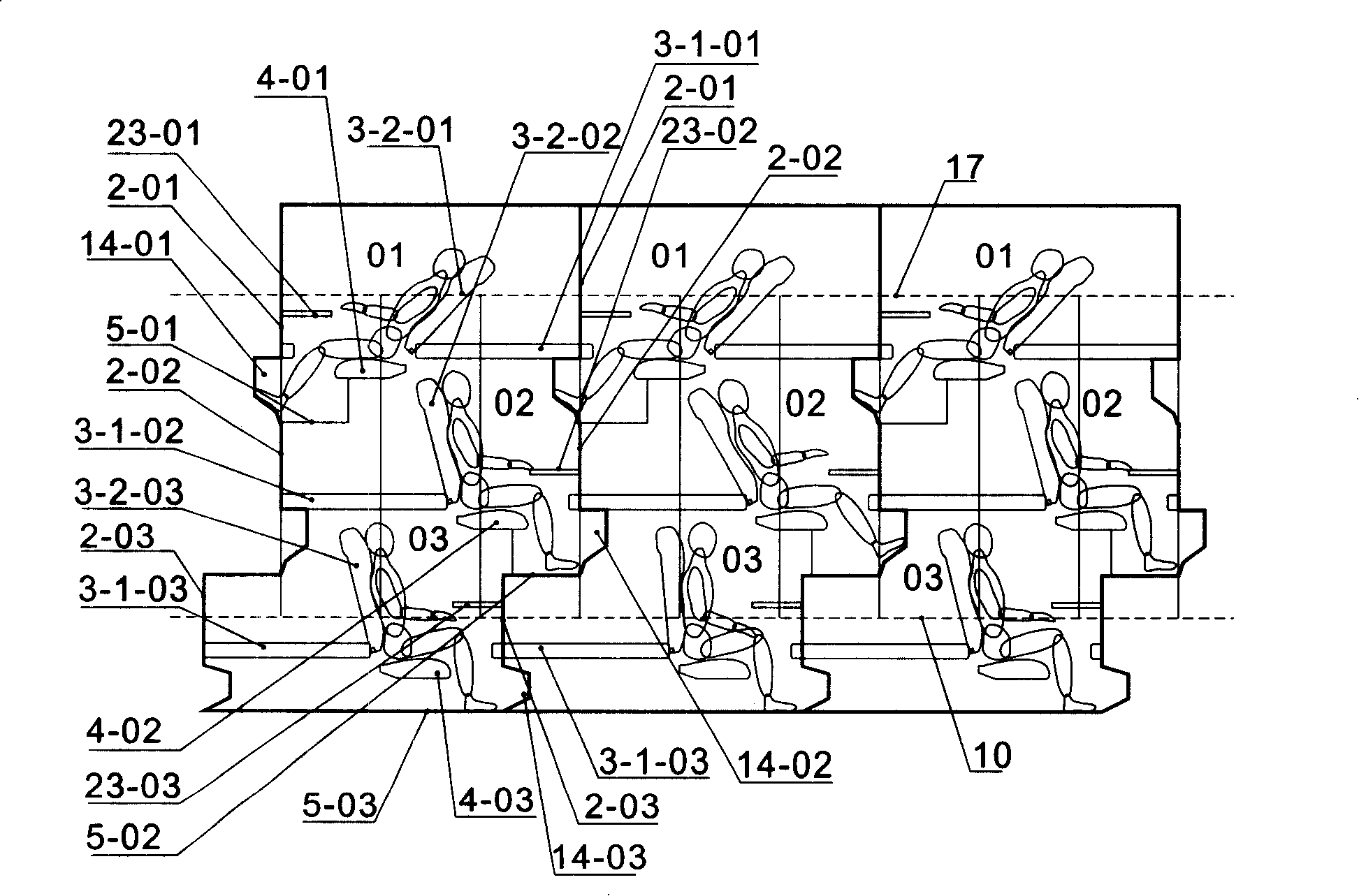

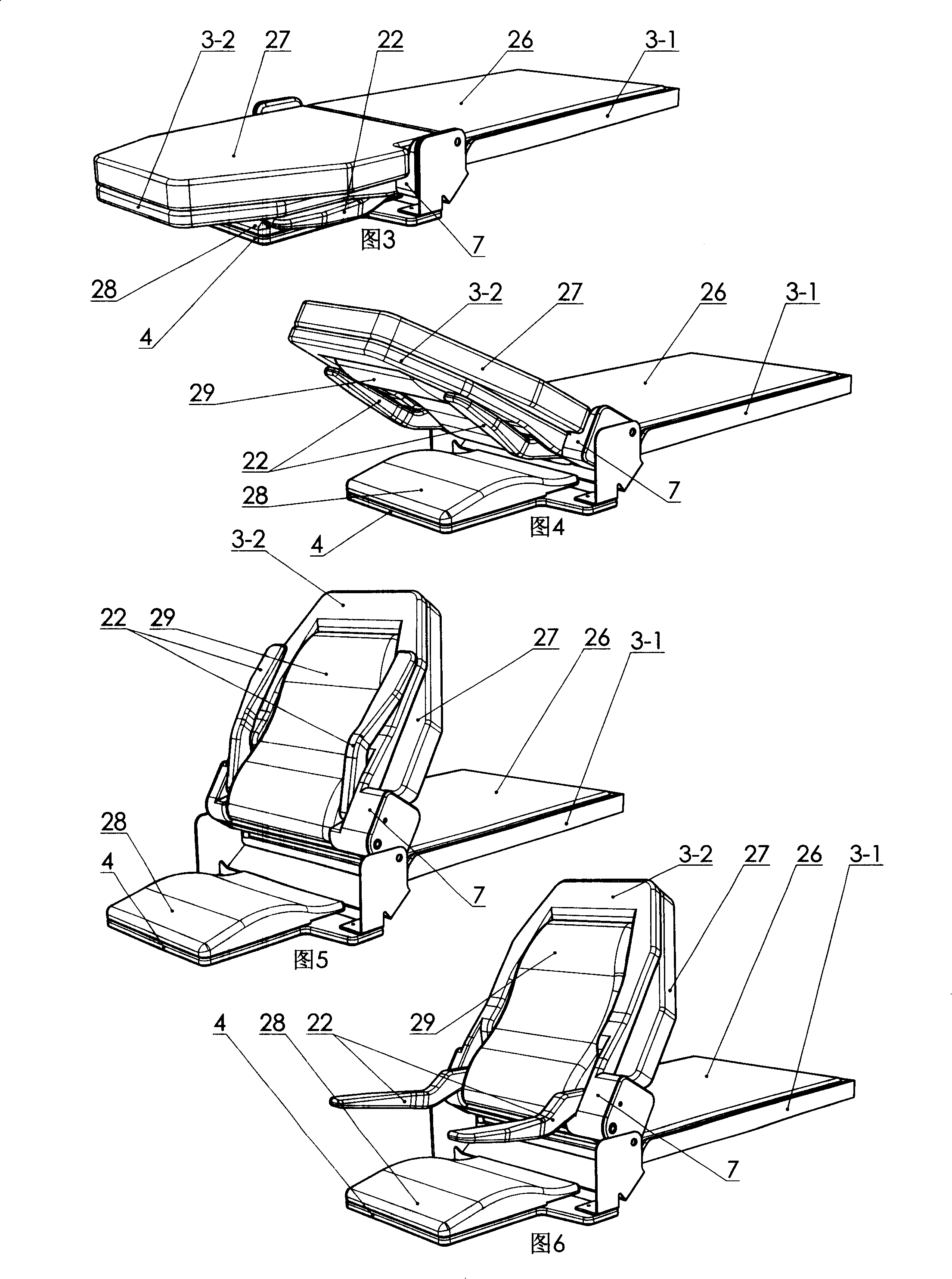

[0133] According to the basic features of the present invention, a bunk layout scheme of a three-layer sleeping cabin is as follows: figure 1 As shown, the head and tail of all the beds in this scheme have the same orientation, and the upper and lower floors are misaligned with each other, and the misalignment range is about a quarter of the length of a sleeping cabin, which is about 0.5 meters. Partition wall 2 is shared between adjacent sleeping cabins on the same floor. The foot hole 14-01 and the floor 5-01 in the top sleeping cabin 01 are just embedded in the upper space between the fixed bed board 3-1-02 of the middle sleeping cabin 02 below it and the partition wall 2-02 at the end of the bed. The space is partially occupied, which has the least impact on the lying activities of people living in the middle sleeping cabin. The foot hole 14-02 in the middle-level sleeping cabin 02 also just embeds the upper space between the fixed bed board 3-1-03 of the bottom sleeping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com