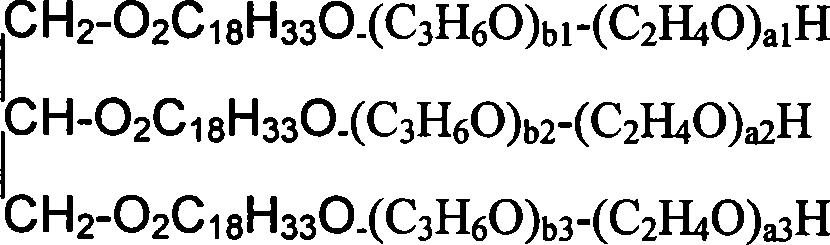

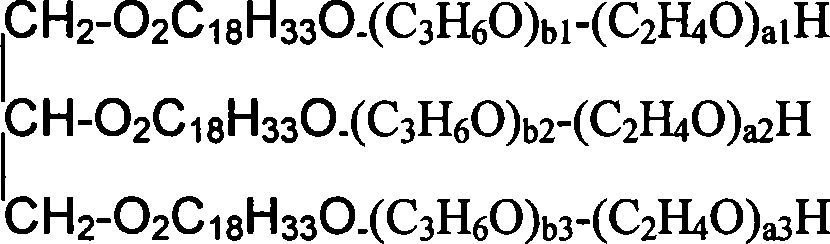

Epoxy propane/epoxy ethane block copolyether and its preparation method and use

A technology of ethylene oxide block and propylene oxide, which is applied in the fields of application, transportation and packaging, chemical instruments and methods, etc., can solve the problems of non-systematic research on additives, restricting the development of water formulations, etc., and achieve good emulsification and stability High performance and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Put 700g of castor oil and 1.5g of catalyst KOH into a 1L reactor, replace the reactor with nitrogen, vacuumize and dehydrate, raise the temperature to 110°C, and then vacuum strip gas for 2 hours, then feed 280g of PO (propylene oxide) to control The reaction temperature is 100-150°C, the pressure is 0.1-0.6MPa, after the PO is fed, the reaction is aged for 1.5hr, after neutralization, adsorption, dehydration, degassing, and filtering with a leaf filter to obtain castor oil polymer with an average molecular weight of 1300. Oxypropylene ether ether (EL-1).

[0020] Put 260g of castor oil polyoxypropylene ether ether (EL-1) and 0.05g of bimetallic catalyst DMC into a 1L reactor, replace the reactor with nitrogen, vacuumize and dehydrate, raise the temperature to 110°C, and vacuum strip the gas for 2 hours. Then 540g of PO (propylene oxide) was introduced, the reaction temperature was controlled at 120-170°C, and the pressure was 0.1-0.6MPa. Pass into 200 grams of EO (et...

Embodiment 2

[0023] Put 700g of castor oil and 1.5g of catalyst KOH into a 1L reactor, replace the reactor with nitrogen, vacuumize and dehydrate, raise the temperature to 110°C, and then vacuum strip gas for 2 hours, then feed 280g of PO (propylene oxide) to control The reaction temperature is 100-150°C, the pressure is 0.1-0.6MPa, after the PO is fed, the reaction is aged for 1.5hr, after neutralization, adsorption, dehydration, degassing, and filtering with a leaf filter to obtain castor oil polymer with an average molecular weight of 1300. Oxypropylene ether ether (EL-1).

[0024] Put 260g of castor oil polyoxypropylene ether ether (EL-1) and 0.04g of bimetallic catalyst DMC into a 1L reactor, replace the reactor with nitrogen, vacuumize and dehydrate, raise the temperature to 110°C, and vacuum strip the gas for 2 hours. Then 560g of PO (propylene oxide) was introduced, the reaction temperature was controlled at 120-170°C, and the pressure was 0.1-0.6MPa. Pass into 200 grams of EO (et...

Embodiment 3

[0026] Put 700g of castor oil and 1.5g of catalyst KOH into a 1L reactor, replace the reactor with nitrogen, vacuumize and dehydrate, raise the temperature to 110°C, and then vacuum strip gas for 2 hours, then feed 280g of PO (propylene oxide) to control The reaction temperature is 100-150°C, the pressure is 0.1-0.6MPa, after the PO is fed, the reaction is aged for 1.5hr, after neutralization, adsorption, dehydration, degassing, and filtering with a leaf filter to obtain castor oil polymer with an average molecular weight of 1300. Oxypropylene ether ether (EL-1).

[0027] Put 260g of castor oil polyoxypropylene ether ether (EL-1) and 0.06g of bimetallic catalyst DMC into a 1L reactor, replace the reactor with nitrogen, vacuumize and dehydrate, raise the temperature to 110°C, and vacuum strip the gas for 2 hours. Then 560g of PO (propylene oxide) was introduced, the reaction temperature was controlled at 120-170°C, and the pressure was 0.1-0.6MPa. Pass into 220 grams of EO (et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com