Hydrogen storing container hydrogen environment fatigue test system

A technology for hydrogen storage containers and fatigue testing, which is applied in the testing of machine/structural components, instruments, and the application of stable tension/pressure to test the strength of materials. It can solve problems such as low efficiency and shorten the service life of the system. Reliability and safety, ensuring safety, reducing the effect of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

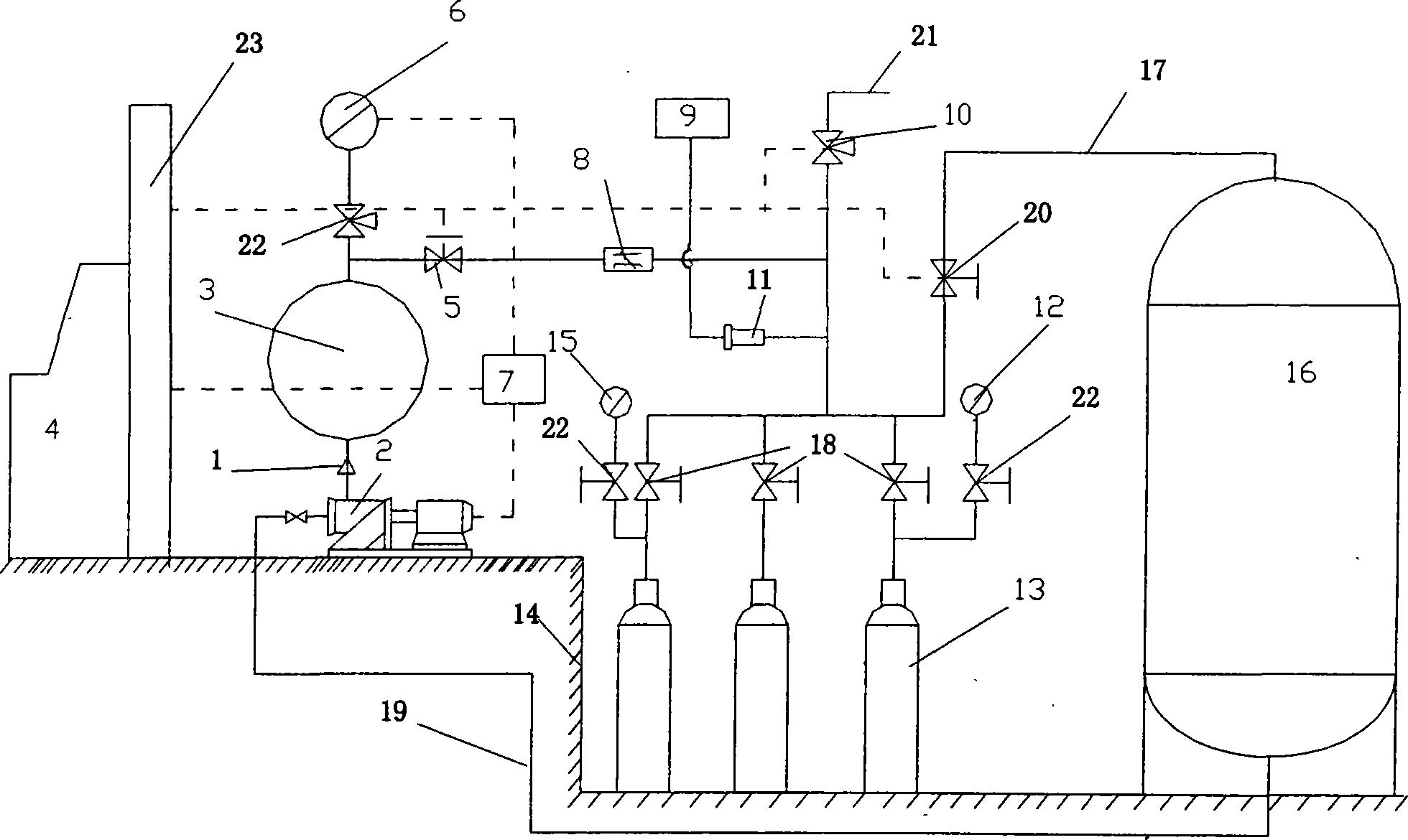

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] As shown in the accompanying drawings, the present invention includes a high-pressure hydrogen storage container 3 and a low-pressure hydrogen storage container 16. One end of the high-pressure hydrogen storage container 3 passes through the explosion-proof pressure reducing valve 5, the regulating flow control valve 8, the first normally open stop valve 18, and the test The container pressure relief valve 20 is respectively connected with a plurality of parallel test containers 13 and low-pressure hydrogen storage containers 16 through a high-pressure resistant pipeline 17; The other end of the high-pressure hydrogen storage container 3 is connected to form a circulation loop; on the high-pressure pipeline between the first normally open stop valve 18 and the vent valve 10, a pressure sensor 11 and a circulation recording device 9 are installed; A second normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com