Car air-conditioner frequency conversion control system and its method

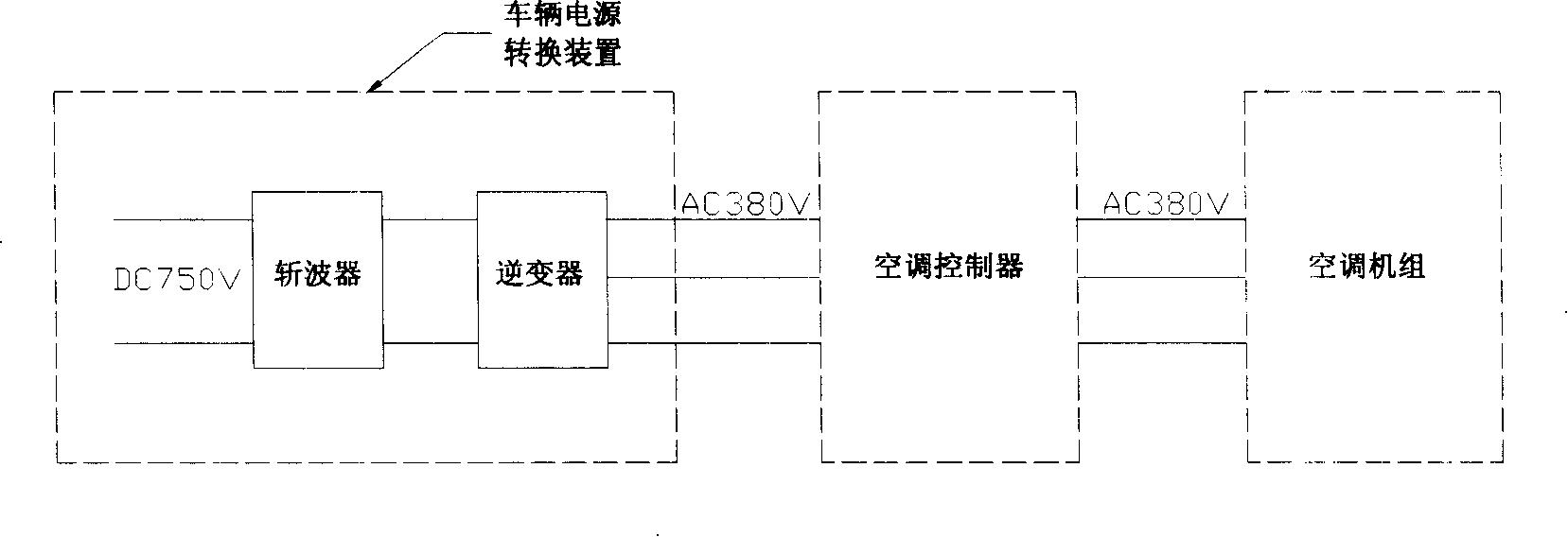

A frequency conversion control and vehicle air conditioning technology, applied in the field of frequency conversion compressors, can solve problems such as difficulty in adapting to a variety of rail vehicle climatic environments, difficulty in achieving precise temperature regulation, large energy loss, etc., to simplify the power conversion process and improve power efficiency. , the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

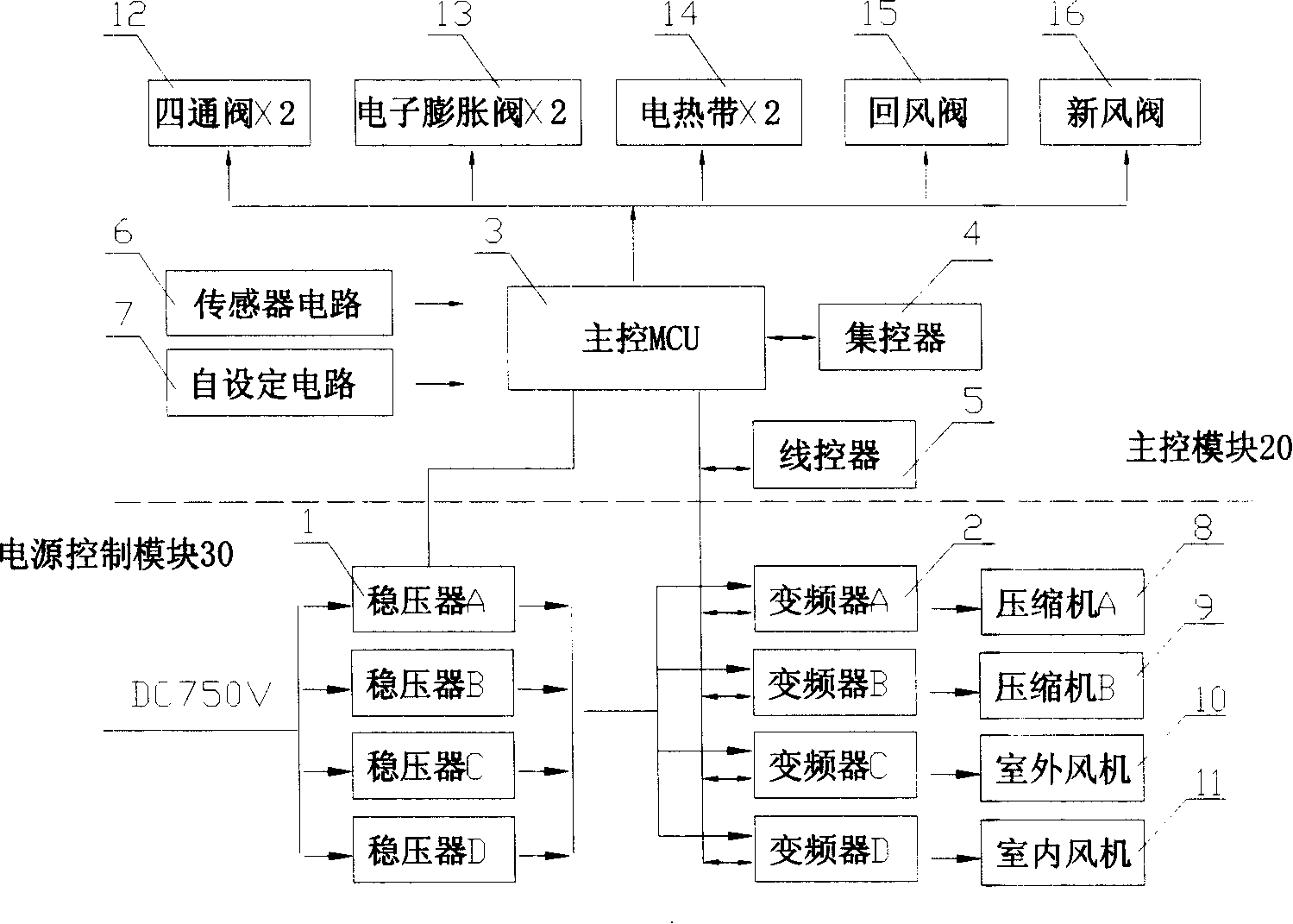

[0028] Example 1, such as Figure 2 to Figure 4 As shown, the vehicle air conditioner frequency conversion control system mainly includes a main control module 20 and a power control module 30 . in,

[0029] Main control module 20, including main control MCU3, centralized controller 4, wire controller 5, sensor circuit 6, self-setting circuit 7, two sets of four-way valve control 12, two sets of electronic expansion valve control 13, two sets of electric heating Belt 14, return air valve 15 and fresh air valve 16.

[0030] The main control MCU 3 of the main control module 20, one of its communication ports is connected with the centralized controller 4 and the vehicle communication bus through the RS485 circuit, and the other communication port is connected with the wire controller 5 and the frequency conversion device 2 through the asynchronous communication bus. connect.

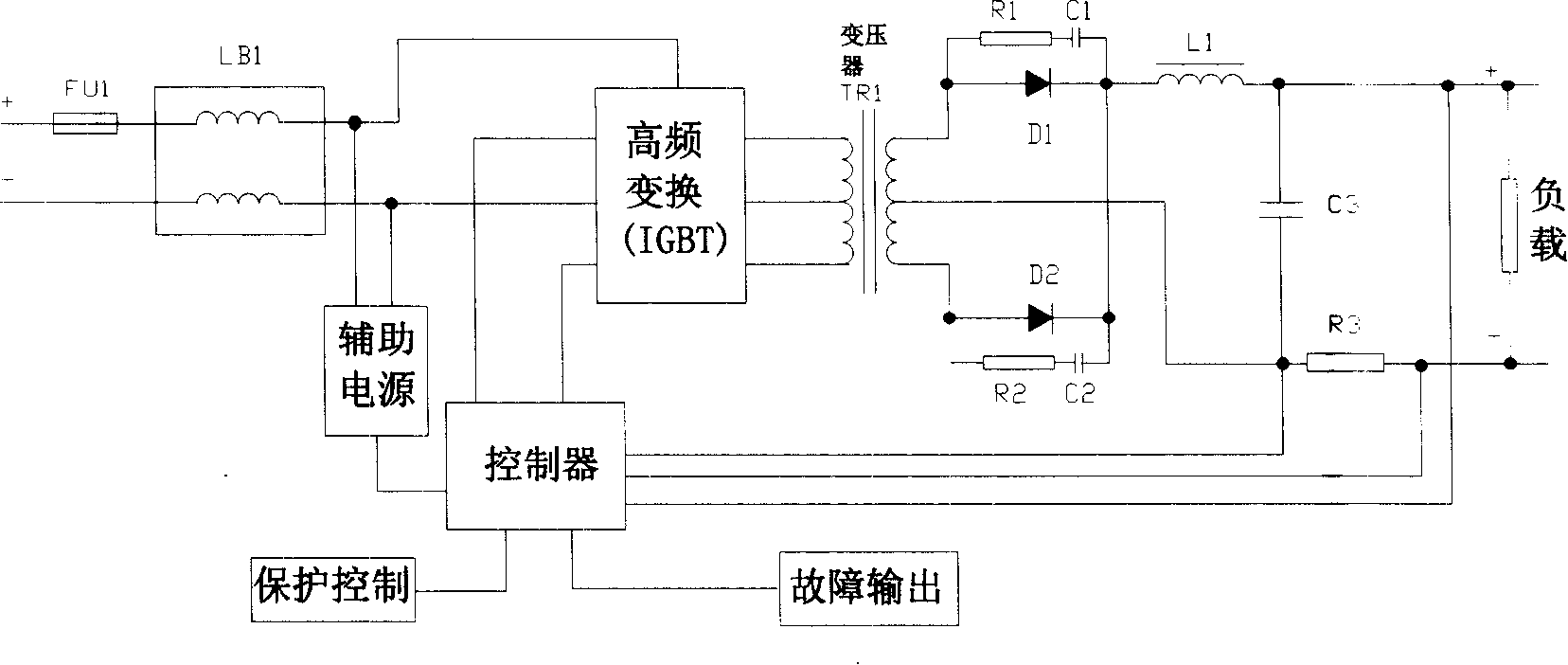

[0031] The power control module 30 includes a stabilized power supply 1 , a frequency conversion dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com