Method for extracting low methoxyl pectin from ficus pumila perianth

A technology of low-ester pectin and perianth, applied in the direction of pharmaceutical formulas, medical preparations containing active ingredients, plant raw materials, etc., can solve problems such as waste of resources, and achieve the effects of fewer production processes, high yields, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

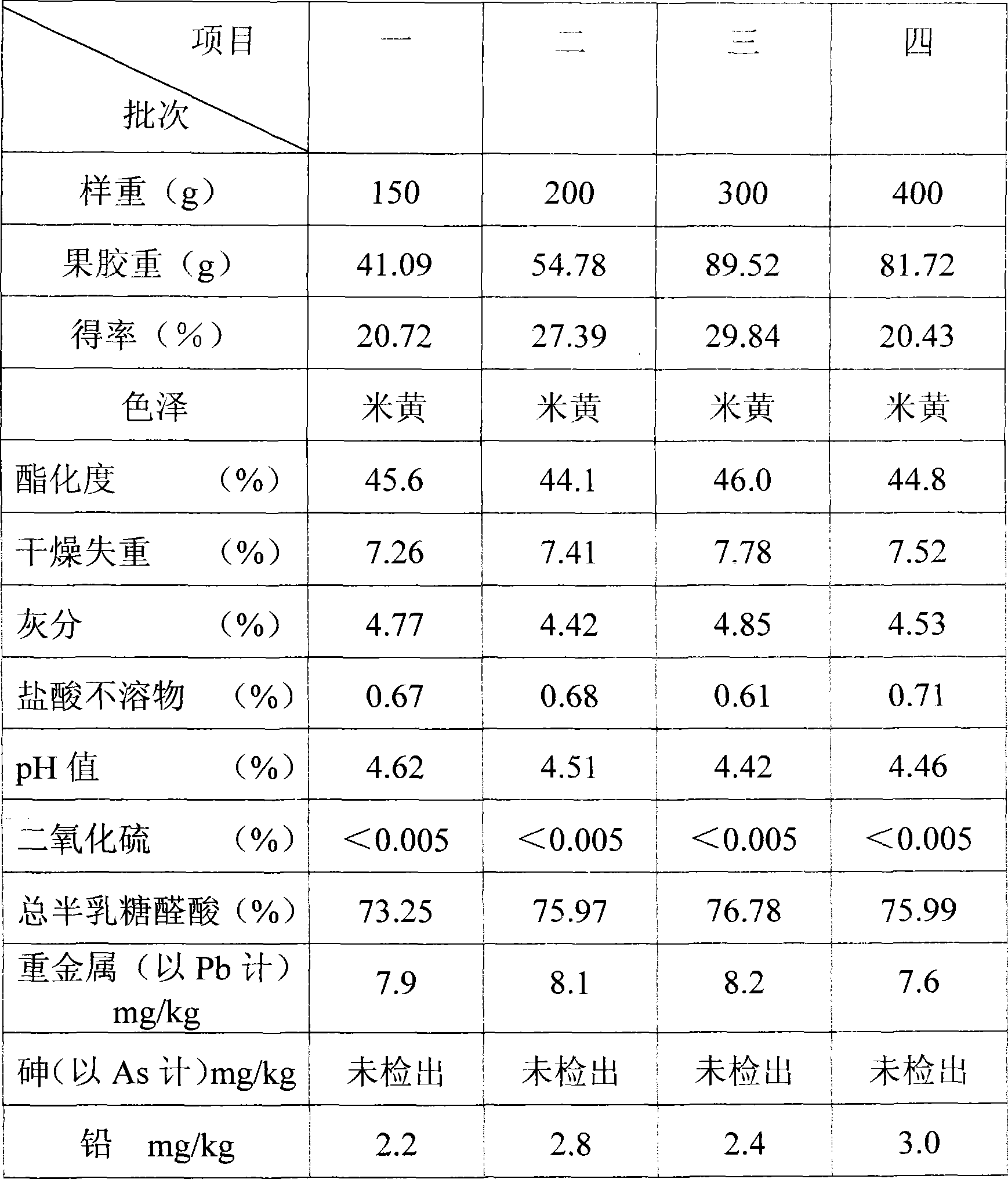

Embodiment 1

[0013] The Ficus pumila flower was crushed to 0.5cm pericarp, rinsed in water at 70℃ for 20min, filtered and dried in an oven at 70℃. Weigh 150g of dried Ficus pumila quilt, add 20 times the weight of water to mix, adjust pH to 1.0 with acid, heat to 85°C, fully stir for 80min, filter through plate and frame filter press to obtain filtrate. 0.3% (w / v) activated carbon was added to the filtrate, stirred at 65°C for 20 minutes, and filtered to remove the activated carbon after decolorization. Add 1.5 to 2.0 times the volume of 95% edible ethanol to the decolorized pectin extract for precipitation, centrifuge (rotation speed is 4800r / min), the filter residue obtained after centrifugation is washed with dilute alcohol, and vacuum dried at 48°C for 4 hours , Then take out the pectin product which is crushed and sieved, and the filtrate is processed for ethanol recovery.

Embodiment 2

[0015] The Ficus pumila flower was crushed to 0.5cm pericarp, rinsed in water at 70℃ for 20min, filtered and dried in an oven at 70℃. Weigh 200g of dried Ficus pumila quilt, add 25 times the weight of water to mix, adjust pH to 1.0 with acid, heat to 85°C, fully stir for 80min, filter by plate and frame filter press to obtain filtrate. 0.3% (w / v) activated carbon was added to the filtrate, stirred at 65°C for 20 minutes, and filtered to remove the activated carbon after decolorization. Add 1.5 to 2.0 times the volume of 95% edible ethanol to the decolorized pectin extract for precipitation, centrifuge (rotation speed is 5000r / min), the filter residue obtained after centrifugation is washed with dilute alcohol, and vacuum dried at 50℃ for 4.5h , Then take out the pectin product which is crushed and sieved, and the filtrate is processed for ethanol recovery.

Embodiment 3

[0017] The Ficus pumila flower was crushed to 0.35cm pericarp, rinsed in 70℃ water for 20min, filtered and dried in an oven at 70℃. Weigh 300 g of dried Ficus pumila quilt, add 15 times the weight of water and mix, adjust the pH to 1.0 with acid, heat to 90°C, fully stir for 100 min, filter through a plate and frame filter press to obtain the filtrate. 0.35% (w / v) activated carbon was added to the filtrate, stirred at 60°C for 25 minutes, and filtered to remove the activated carbon after decolorization. Add 1.5-2.0 times the volume of 95% edible ethanol to the decolorized pectin extract for precipitation, centrifugation (rotating speed 5500r / min), the filter residue after centrifugation is washed with dilute alcohol, and vacuum dried at 55°C for 5h. Then the pectin product is obtained by pulverizing and sieving, and the filtrate is subjected to ethanol recovery treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of esterification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com