Full-automatic double-station circumference welding machine

A circular welding, double-station technology, applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems that users are not easy to accept, difficult to repair by themselves, high production cost, etc., to reduce the number of purchases, ensure quality and work safety High reliability and high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

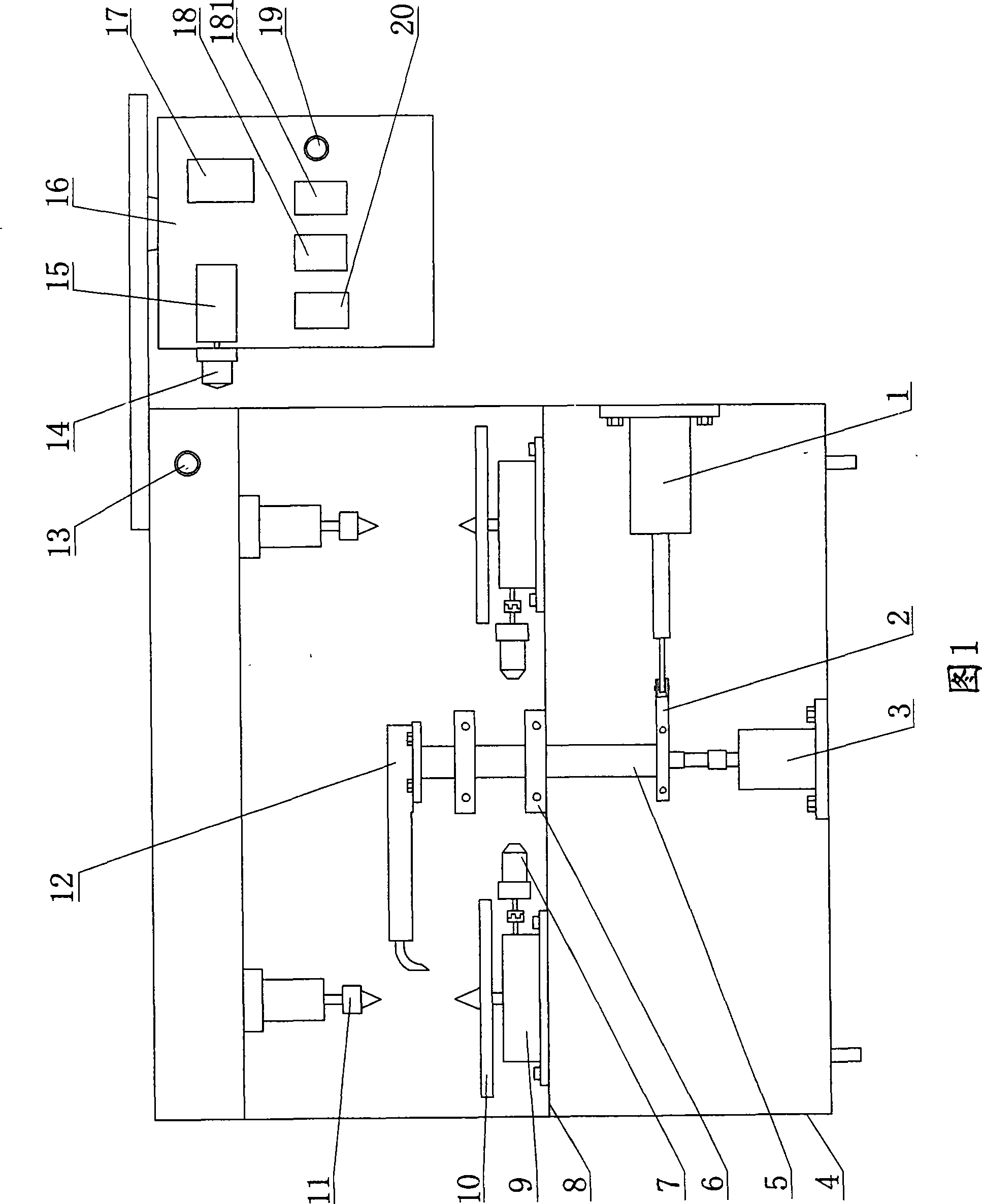

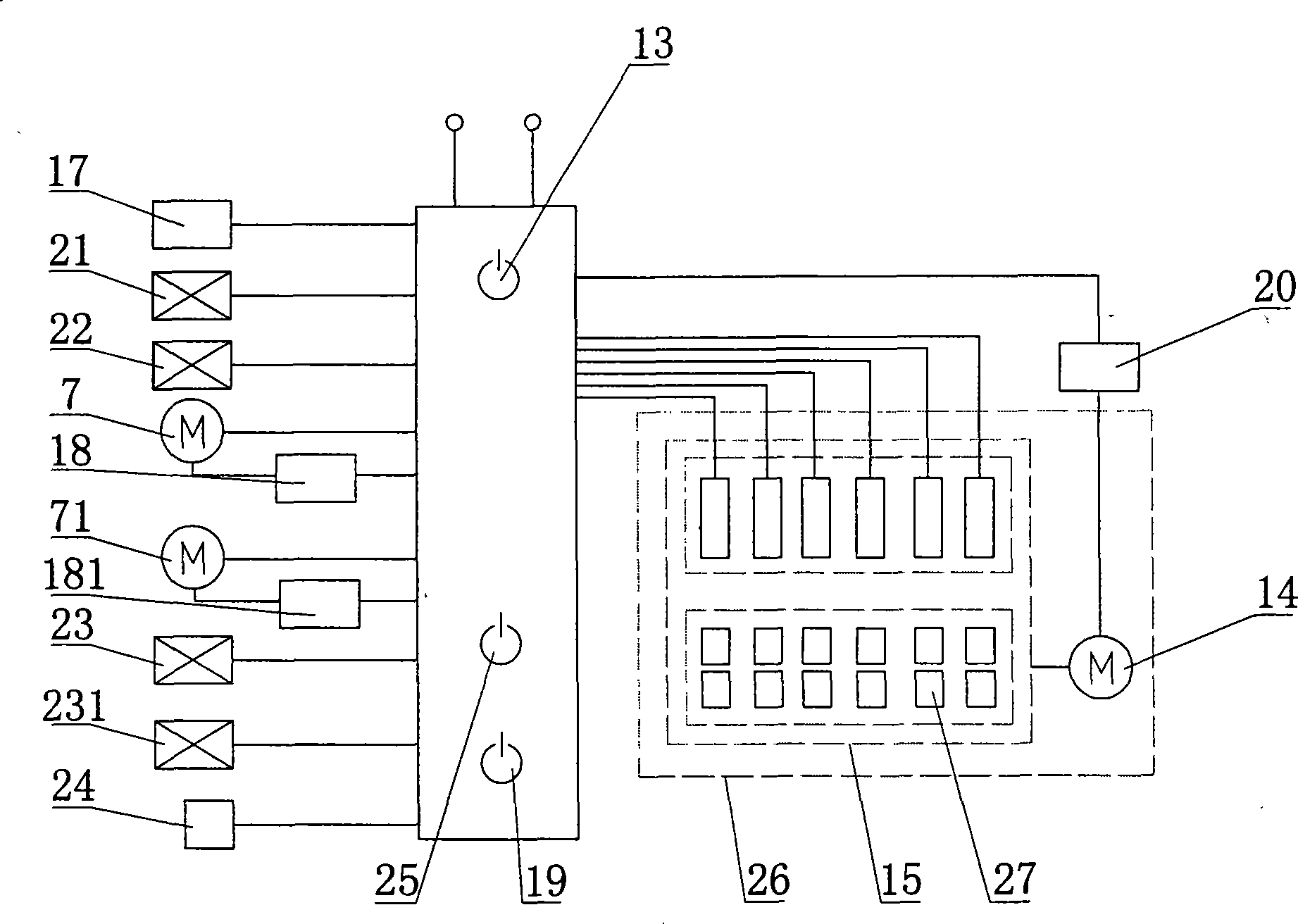

[0012] A kind of full-automatic double-station circumferential welding machine shown in Fig. 1 comprises power supply, frame 4, control box 16, and double-station welding group is installed on the workbench of frame, and described double-station welding group comprises worm gear Reducer 9, rotating tray 10 and speed-regulating motor 7, rotating tray 10 is installed on the worm gear reducer 9, speed-regulating motor 7 is connected with worm gear reducer 9; Cylinder ejector rod 11, slide bar 5 is installed in the middle of two groups of rotating trays 10, two slide bar positioning sleeves 6 are arranged on slide bar 5, the bottom end of slide bar 5 is connected with vertical cylinder 3, and slide bar 5 is pushed by vertical cylinder 3 to form In the state of moving up and down, the rocker arm 2 is installed at the bottom of the slide bar 5, and the rock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com