Method for preparing polythene glass fibre resin-immersing composite pipe

A technology of glass fiber and production method, which is applied in the production field of polyethylene composite pipe, can solve the problems of affecting the use and poor pressure bearing capacity of large and medium-diameter pipes, and achieve the effects of reducing overall cost, optimizing performance and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Manufacture a polyethylene plastic pipe with a certain diameter and a certain length first, and install it on the winding machine through a clamp, so that the polyethylene plastic pipe rotates at a constant speed and at the same time makes a uniform axial movement, and presses 5 strands of glass fiber into the resin tank through the roller. After dipping in fat, it is evenly wound on the pipe wall of the polyethylene plastic pipe. The thickness and number of layers of the winding are determined by the pressure resistance of the pipe; after 8 hours of curing and curing at a temperature of about 70 degrees, the higher the temperature, the curing The shorter the time, the polyethylene fiberglass resin-impregnated composite pipe is done.

Embodiment 2

[0013] Manufacture polyethylene plastic pipes with a certain diameter and length first, and install them on the winding machine through clamps, so that the polyethylene plastic pipes rotate at a constant speed and at the same time make uniform axial movements, and press 20 strands of glass fibers into the resin tank through rollers After dipping in fat, it is evenly wound on the pipe wall of the polyethylene plastic pipe. The thickness and number of layers of the winding are determined by the pressure resistance of the pipe; after curing and curing for 5 hours at a temperature of about 90 degrees, the higher the temperature, the better The shorter the time, the polyethylene fiberglass resin-impregnated composite pipe is done.

Embodiment 3

[0015] Manufacture a polyethylene plastic pipe with a certain diameter and a certain length, install it on the winding machine through a clamp, make the polyethylene plastic pipe rotate at a constant speed and at the same time make a uniform axial movement, and press 8 strands of glass fiber into the resin tank through the roller After dipping in fat, it is evenly wound on the pipe wall of the polyethylene plastic pipe. The thickness and number of layers of the winding are determined by the pressure resistance of the pipe; after 5-8 hours of curing and curing at a temperature of about 80 degrees, the higher the temperature , the shorter the curing time, the more complete the polyethylene fiberglass resin-impregnated composite pipe.

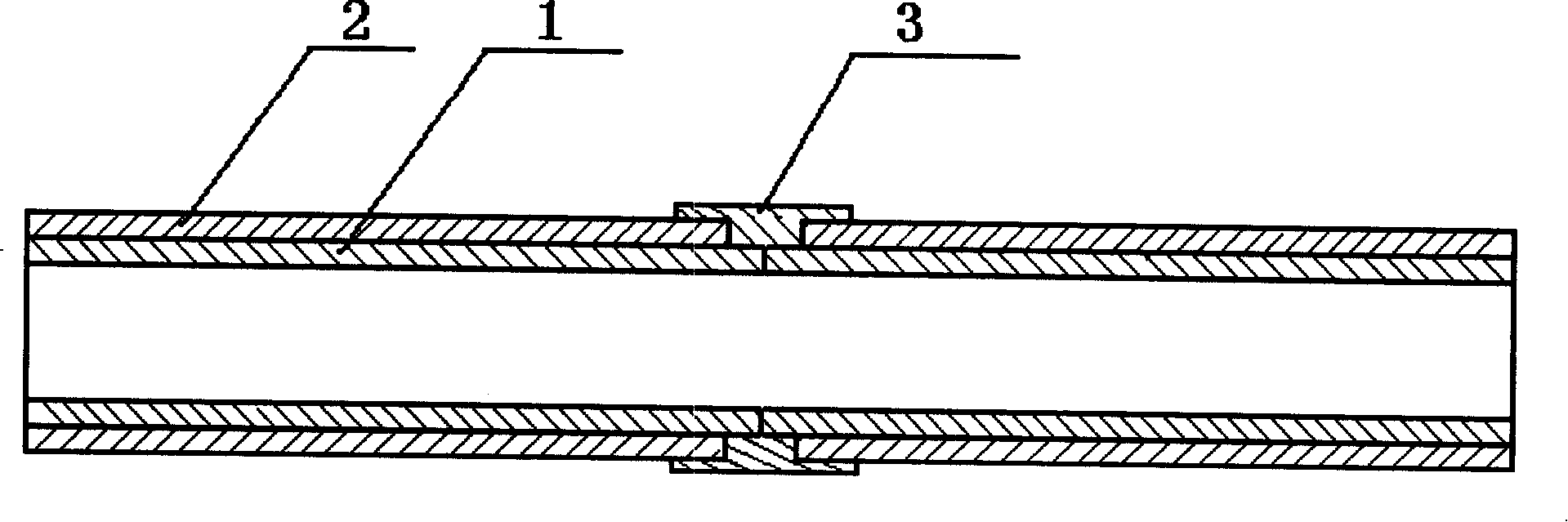

[0016] Refer to attached figure 1 , the produced product is composed of polyethylene pipe 1 and glass fiber layer 2, and the outer layer of polyethylene pipe 1 is provided with resin-impregnated glass fiber layer 2; wherein, when multiple pipes ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com