Method for synthesizing polyurethane/polyacrylate ionomer emuldion

A technology of polyacrylate and synthesis method, applied in the field of synthesis of ionomer emulsion, can solve the problems such as failure to obtain stable emulsion, and achieve the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment one: the following is the example of polyurethane / polyacrylate ionomer emulsion prepared by the present invention, which has the following process and steps:

[0016] (1) Synthesis of cationic polyurethane PU

[0017] Quantitative polyisopropylene glycol (PPG) and toluene diisocyanate (TDI) were stirred at 60° C. for 3 hours (adding catalyst dibutyltin dilaurate and solvent acetone) to form a prepolymer. A measured amount of N-methyldiethanolamine (MDEA) was added, the temperature was still at 60° C., and the reaction was continued for 3 hours. The molar ratio of each reactant in the reaction is: polyisopropylene glycol (PPG): toluene diisocyanate (TDI): N-methyldiethanolamine (MDEA)=1:2:1. Specific dosage: Polyisopropylene glycol (PPG) 0.1mol, toluene diisocyanate (TDI) 0.2mol, N-methyldiethanolamine (MDEA) 0.1mol

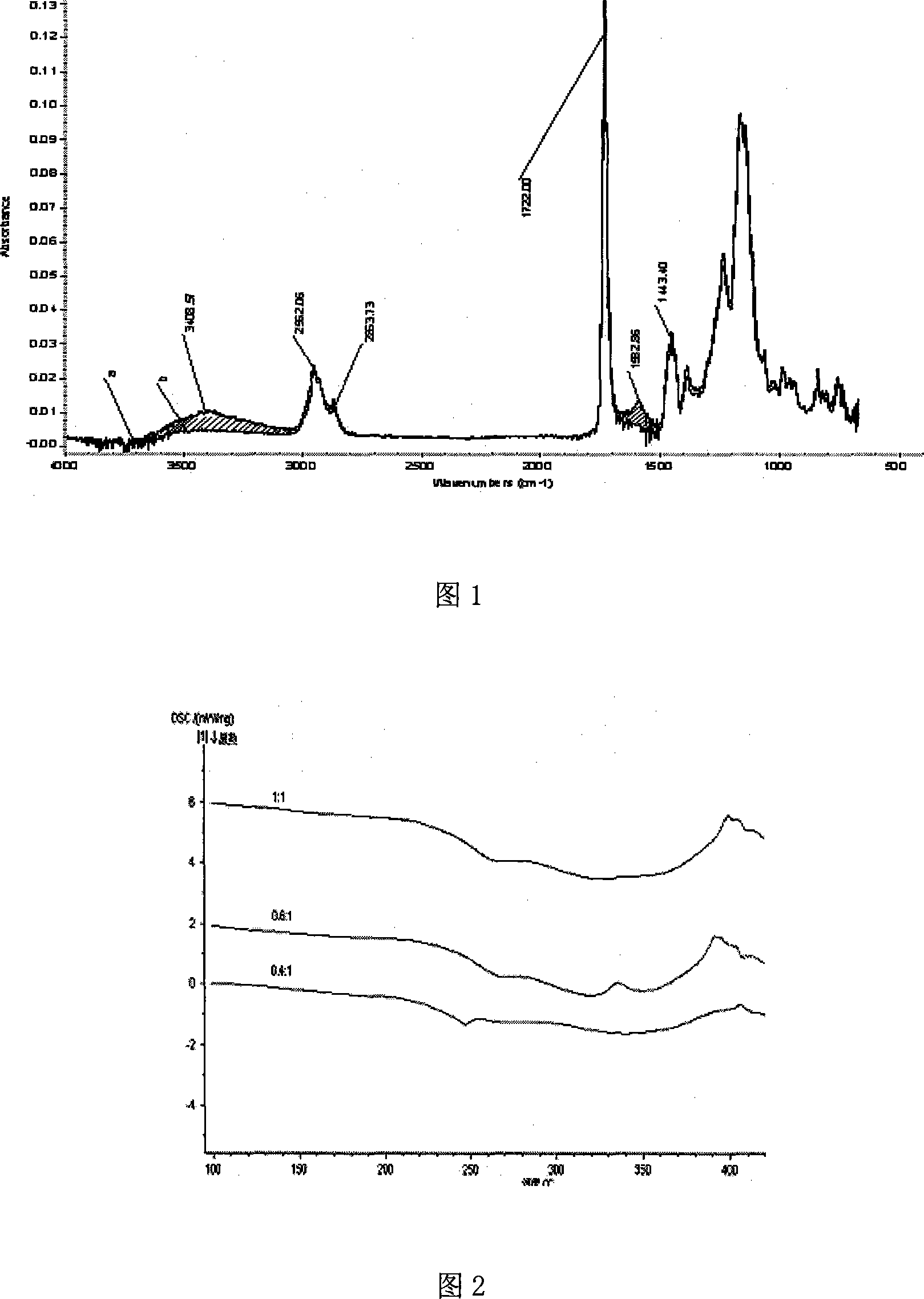

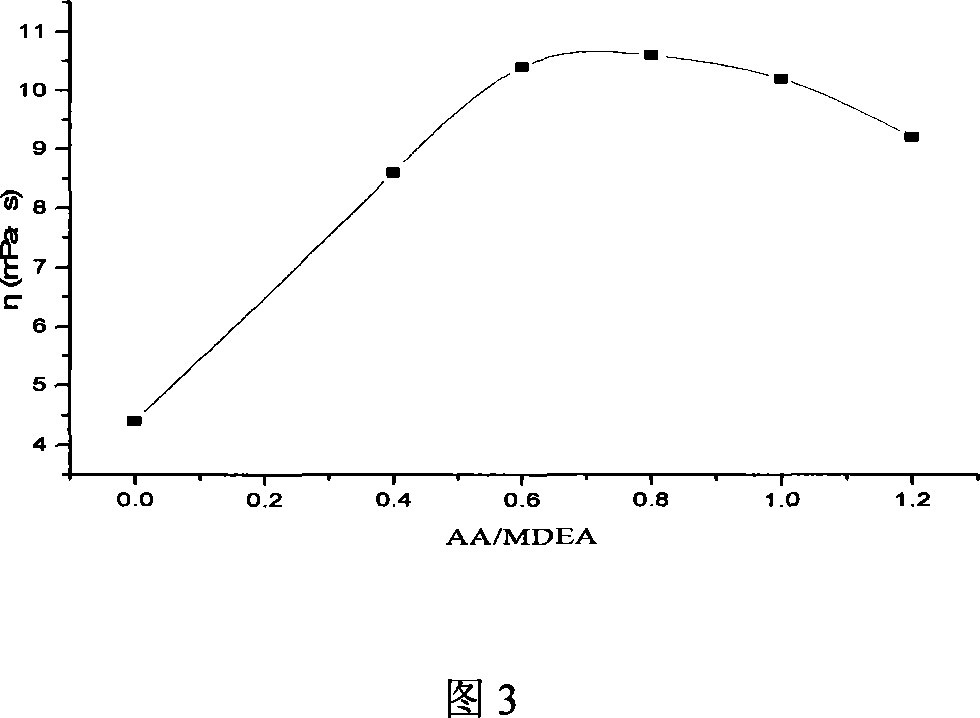

[0018] (2) Synthesis of polyurethane / polyacrylate PUA

[0019] Adjust the pH value of polyurethane PU to 6 with acid, then pour it into water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com