Metal ink

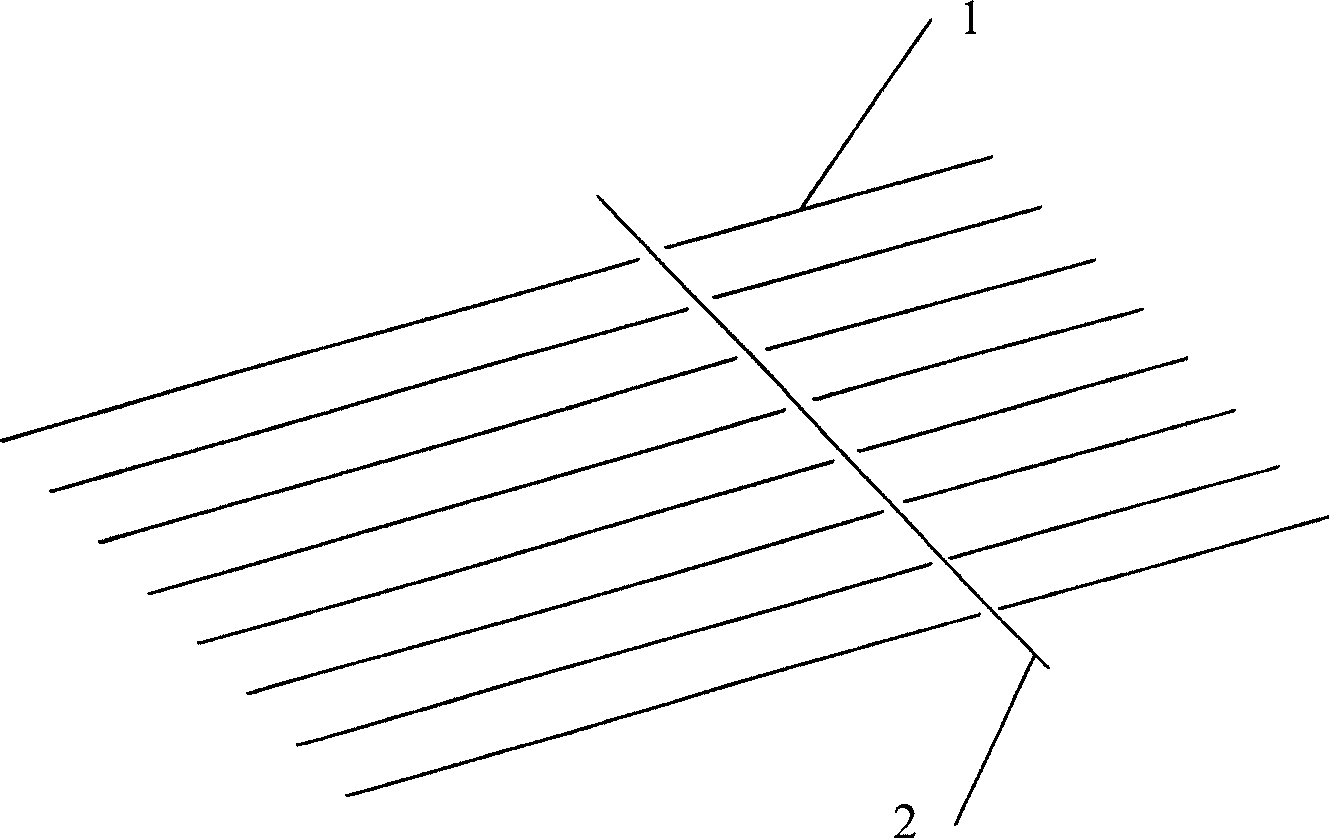

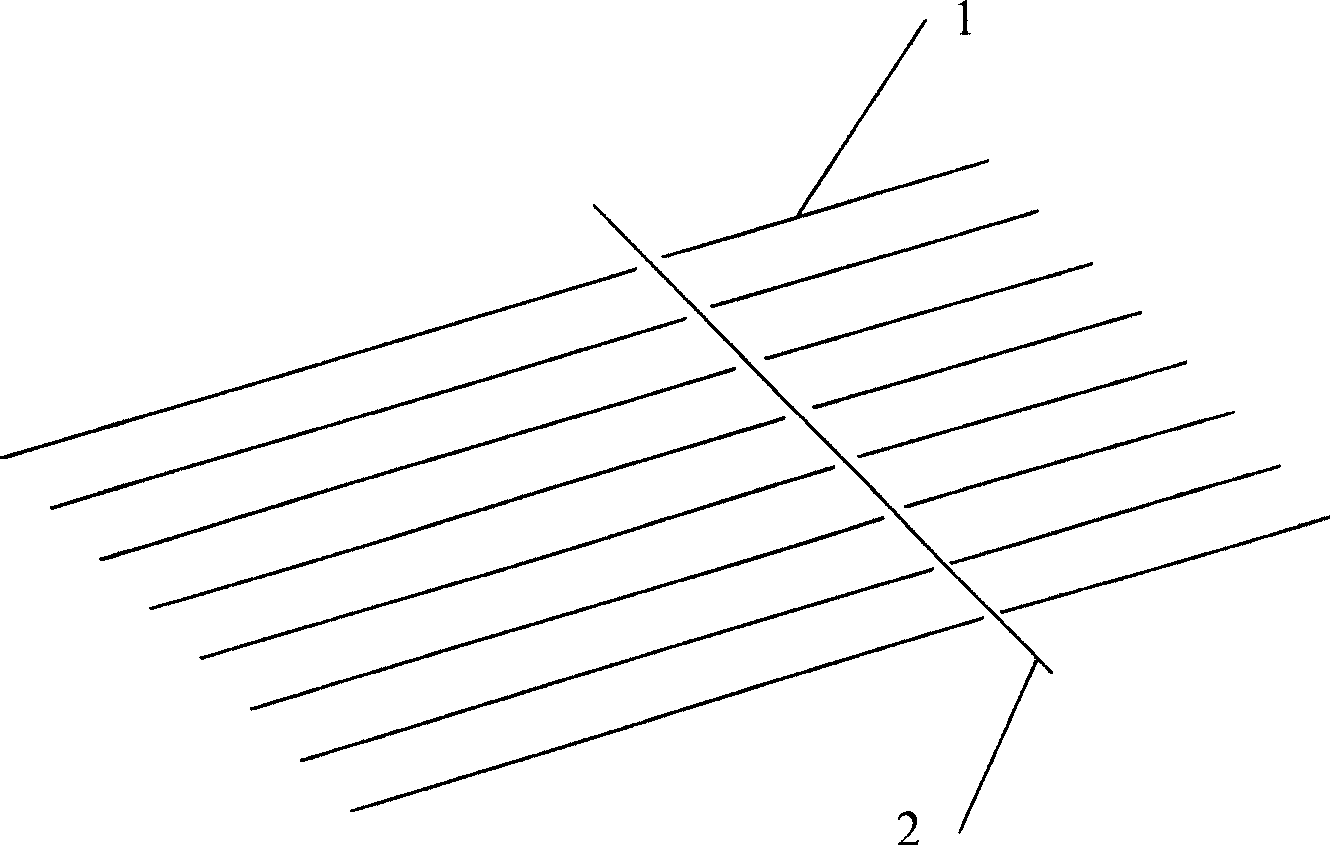

A metal ink and metal pigment technology, applied in the direction of ink, pigment slurry, fibrous filler, etc., can solve the problems of difficult perspective latent image, unrecognized pattern, high precision, and achieve strong anti-counterfeiting performance, improve aesthetics, Latent image printing easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: metallic ink comprises metal pigment, binder, filler, surfactant and polyethylene wax, and wherein binder is alkyd resin oil, high acid value phenolic resin oil, pure phenolic resin oil, and filler is vapor phase dioxide Silicon, transparent calcium carbonate.

[0030] The composition and weight percentage of metallic ink are as follows:

[0031] Flake silver powder 15%

[0032] Alkyd Oil 12%

[0033] High acid value phenolic resin oil 25%

[0034] Pure Phenolic Oil 8%

[0035] Fumed silica 3%

[0036] Transparent Calcium Carbonate 19%

[0037] Surfactant 5.5%

[0038] Polyethylene Wax 8%

[0039] Mineral oil 4%

[0040] Desiccant 0.5%

[0041] The production of metal ink is as follows:

[0042] 1. According to the above formula, weigh the alkyd resin oil, high acid value phenolic resin oil, pure phenolic resin oil, fumed silica, transparent calcium carbonate, surfactant and polyethylene wax accurately, mix them evenly and use three The ink roll...

Embodiment 2

[0045] Embodiment 2: The composition and percentage content of the metal ink used to print the lines of the see-through latent image and the base pattern on one side of the carrier are as follows:

[0046] Flake aluminum powder 20%

[0047] Alkyd Oil 15%

[0048] High acid value phenolic resin oil 20%

[0049] Pure Phenolic Oil 10%

[0050] Fumed silica 5%

[0051] Transparent Calcium Carbonate 15%

[0052] Surfactant 6.7%

[0053] Polyethylene wax 6%

[0054] Mineral oil 2%

[0055] Desiccant 0.3%

[0056] The method and structure of the metallic ink for making a single-sided see-through latent image printed with the metallic ink are as in Example 1.

Embodiment 3

[0057] Embodiment 3: The composition and percentage content of the metal ink used to print the lines of the see-through latent image and the base pattern on one side of the carrier are as follows:

[0058] Flake copper powder 24%

[0059] Alkyd Oil 10%

[0060] High acid value phenolic resin oil 24%

[0061] Pure Phenolic Oil 8%

[0062] Fumed silica 3%

[0063] Transparent Calcium Carbonate 16%

[0064] Surfactant 5.6%

[0065] Polyethylene wax 6%

[0066] Mineral oil 3%

[0067] Desiccant 0.4%

[0068] The method and structure of the metallic ink for making a single-sided see-through latent image printed with the metallic ink are as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com