Method for producing green gasoline without corn grain

A food and green technology, applied in the field of industrial fuel ethanol, can solve the problems of indirect negative impact and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

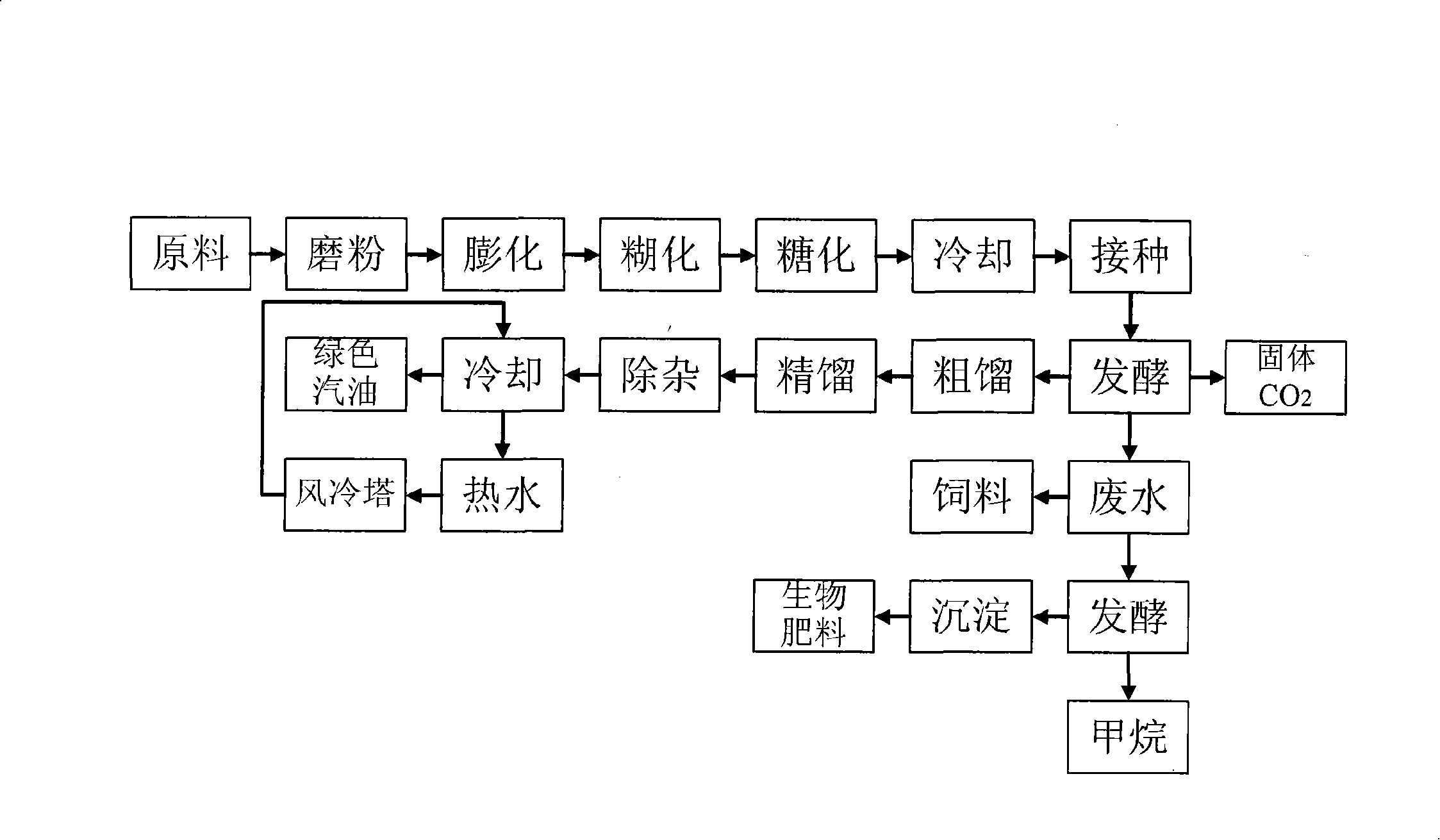

Image

Examples

Embodiment 1

[0021] Pueraria puerariae is dried and pulverized, and the obtained powder is sieved, and then the powder is expanded in a general-purpose extruder, and the expansion temperature is controlled at 200°C.

[0022] After preheating the puffed product at a temperature of 60°C for 30 minutes, at a temperature of 125°C and a pressure of 0.9kg / cm 2 Under the conditions of steaming for 50 minutes, the puffed product is gelatinized.

[0023] Afterwards, under the condition of controlling the temperature at 55°C, add glucoamylase at a weight ratio of 80 units / g of raw materials, stir evenly and keep warm for 20 minutes. This process is commonly known as saccharification.

[0024] Cool the saccharified product to 25°C, put it into a closed container and add distiller's yeast to ferment at a weight ratio of 20 units / g (this process is commonly known as inoculation). The fermented product undergoes crude distillation to remove impurities and rectification to extract liquid ethanol with a ...

Embodiment 2

[0027] Dried corn (scientific name: cassava) is ground into powder, and the obtained powder is sieved, and then the powder is expanded in a general-purpose extruder, and the expansion temperature is controlled at 210°C.

[0028] After preheating the puffed product at a temperature of 70°C for 50 minutes, at a temperature of 128°C and a pressure of 1kg / cm 2 Under the condition of cooking for 100 minutes, the puffed product is gelatinized.

[0029] Afterwards, under the condition of controlling the temperature at 60°C, add glucoamylase at a weight ratio of 100 units / g of raw materials, stir evenly and keep warm for 25 minutes. This process is commonly known as saccharification.

[0030] Cool the saccharified product to 30°C, put it into a closed container and add distiller's koji to fermentation (this process is commonly known as inoculation) at a weight ratio of 100 units / g. The carbon dioxide gas produced is made into solid carbon dioxide by cooling down, that is, dry ice, an...

Embodiment 3

[0033] Dried sweet potato slices are dried and ground into powder, and the obtained powder is sieved, and then the powder is expanded in a general-purpose extruder, and the expansion temperature is controlled at 230°C.

[0034] After preheating the puffed product at a temperature of 75°C for 60 minutes, at a temperature of 126°C and a pressure of 1.1kg / cm 2 Under the condition of cooking for 120 minutes, the puffed product is gelatinized.

[0035] Afterwards, under the condition of controlling the temperature at 65°C, add glucoamylase at a weight ratio of 200 units per gram of raw material, stir evenly and keep warm for 30 minutes. This process is commonly known as saccharification.

[0036] Cool the saccharified product to 35°C, put it into a closed container and add the koji to ferment the raw material at a weight ratio of 300 units / g (this process is commonly known as inoculation). Crude distillation to remove impurities and rectification to extract liquid ethanol with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com