Low-temperature refrigeration method for recycling oil gas

A refrigeration method, oil and gas technology, applied in separation methods, chemical instruments and methods, steam/steam condensers, etc., can solve the problems of large volume, low operation efficiency, and large initial investment of recovery devices, and achieve simple system structure and improved efficiency. The effect of heat exchange efficiency and convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

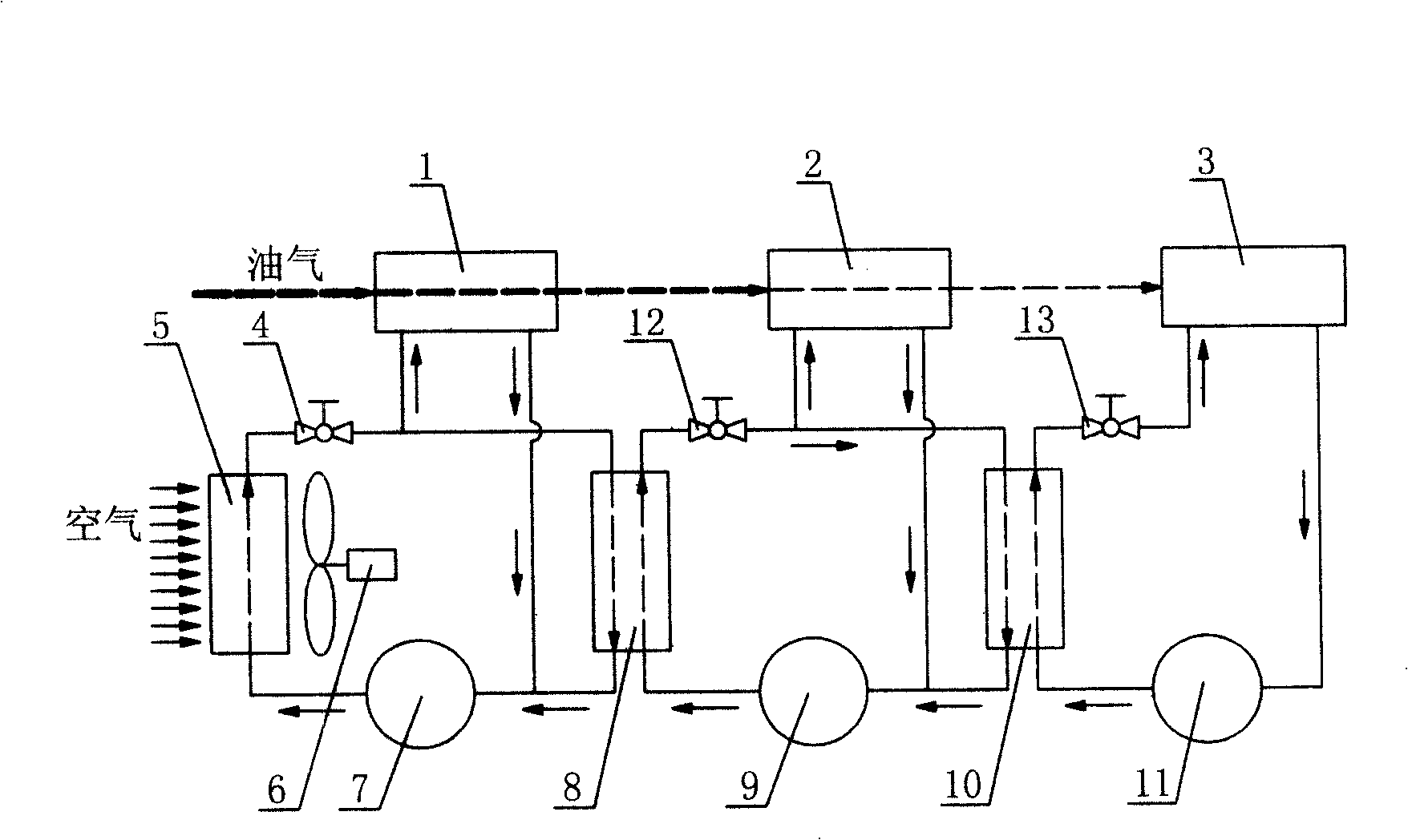

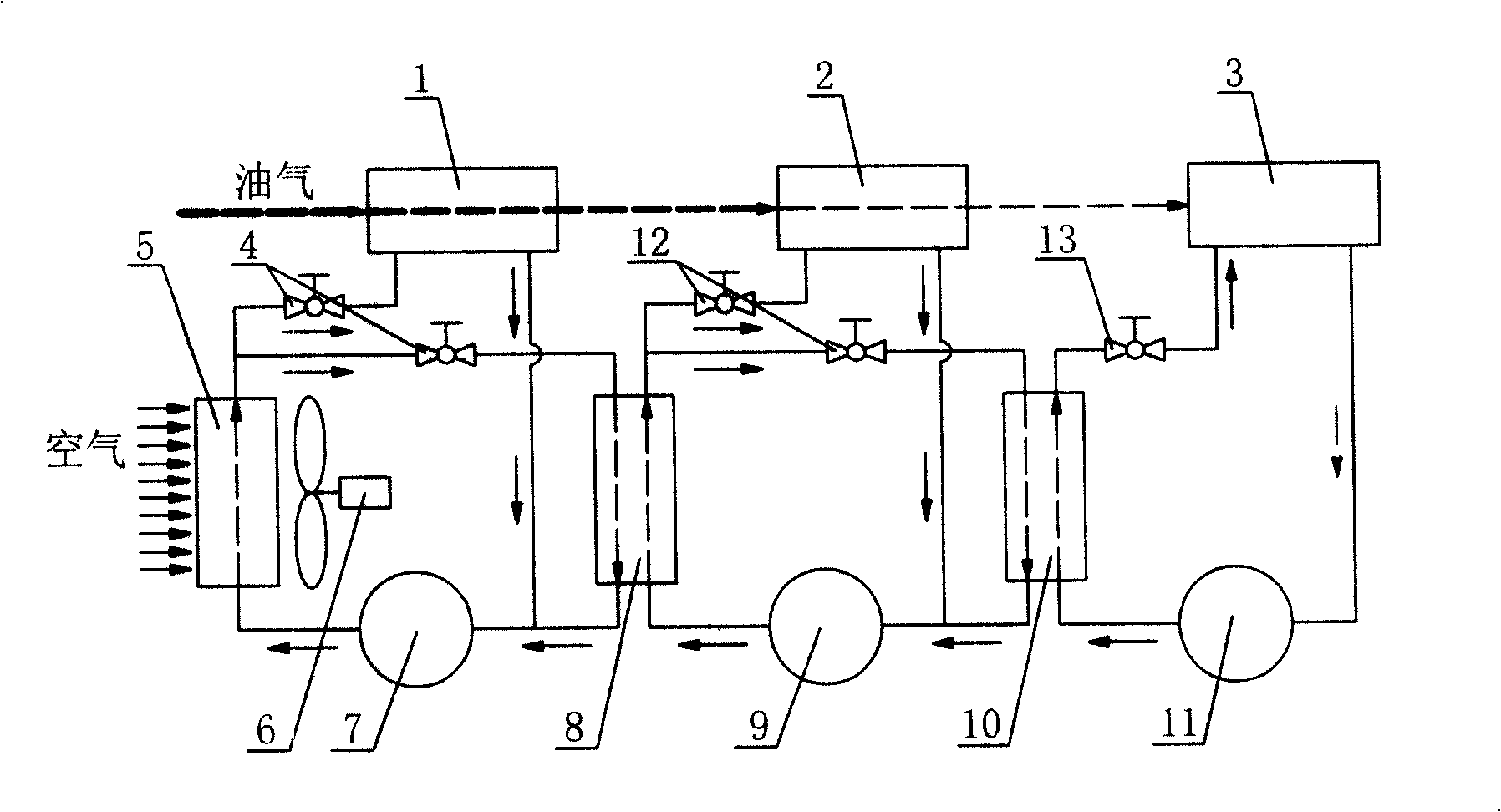

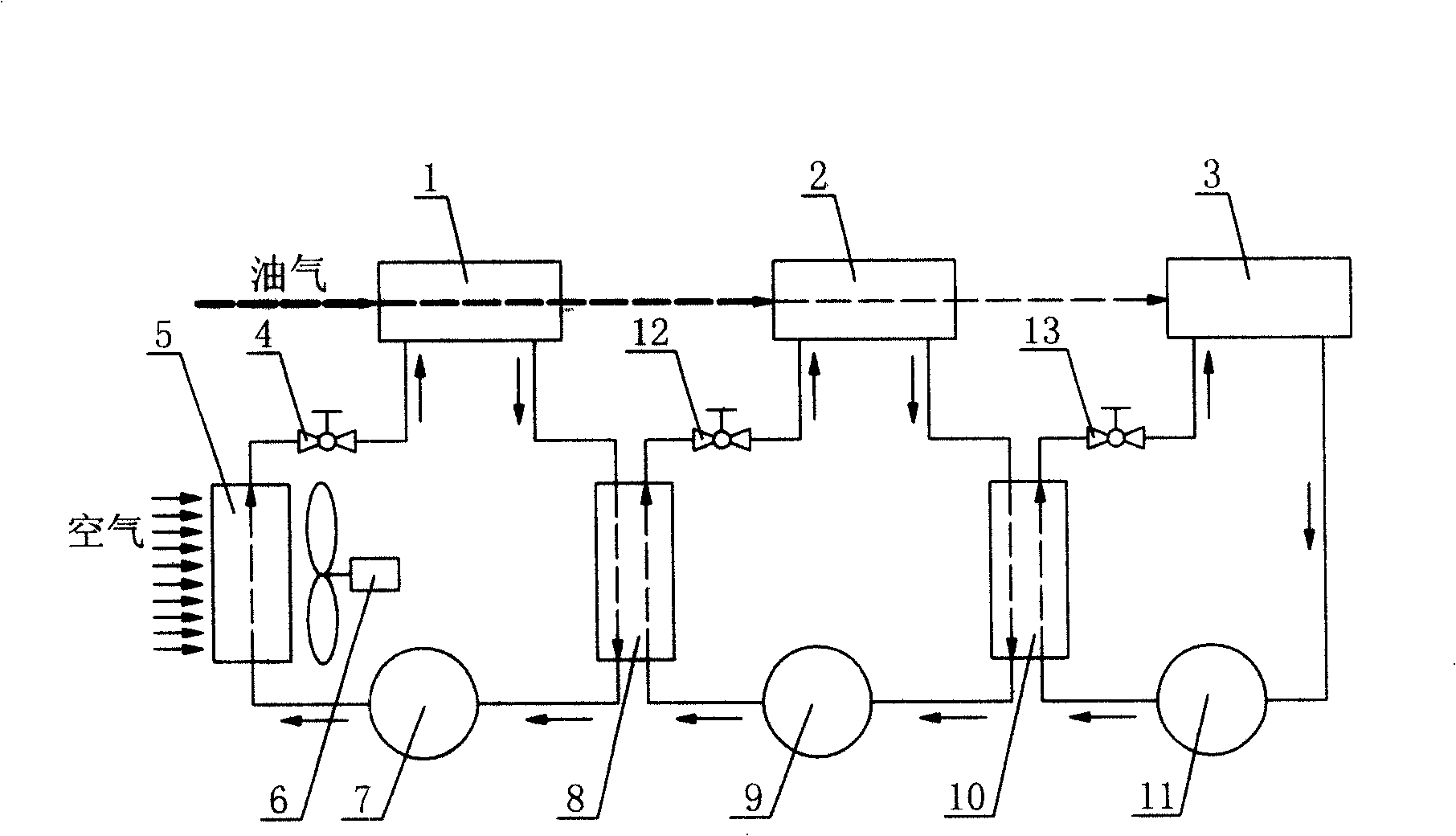

[0018] Such as figure 1 As shown, it is a common throttling parallel connection refrigeration system structure and operation principle diagram. The system includes three-stage refrigeration system. Each stage system has a compressor, a condenser, an expansion valve and an evaporator, and the oil and gas pass through in sequence. The I-level evaporator 1, the II-level evaporator 2 and the III-level evaporator 3 are respectively recovered in each level of evaporator. In the first-stage refrigeration system, the refrigerant enters the first-stage condenser 5 after coming out of the first-stage compressor 7, and exchanges heat with the air in the first-stage condenser 5, and the cooling fan can enhance the heat dissipation effect; the refrigerant is condensed from the first-stage After the device 5 comes out, it is throttled by the first-stage expansion valve 4 to obtain low-temperature and low-pressure refrigerant. The components with higher condensation points are recovered; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com