Side-hanging taper disc type self-adaption two-gear automatic speed changing hub

An automatic variable speed and self-adaptive technology, which is applied in the direction of vehicle gearboxes, wheel transmissions, motion deposition, etc., can solve the problems of small installation space, short continuation distance, motor stalling, etc., and achieves simple and compact structure, The effect of smooth load change and saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

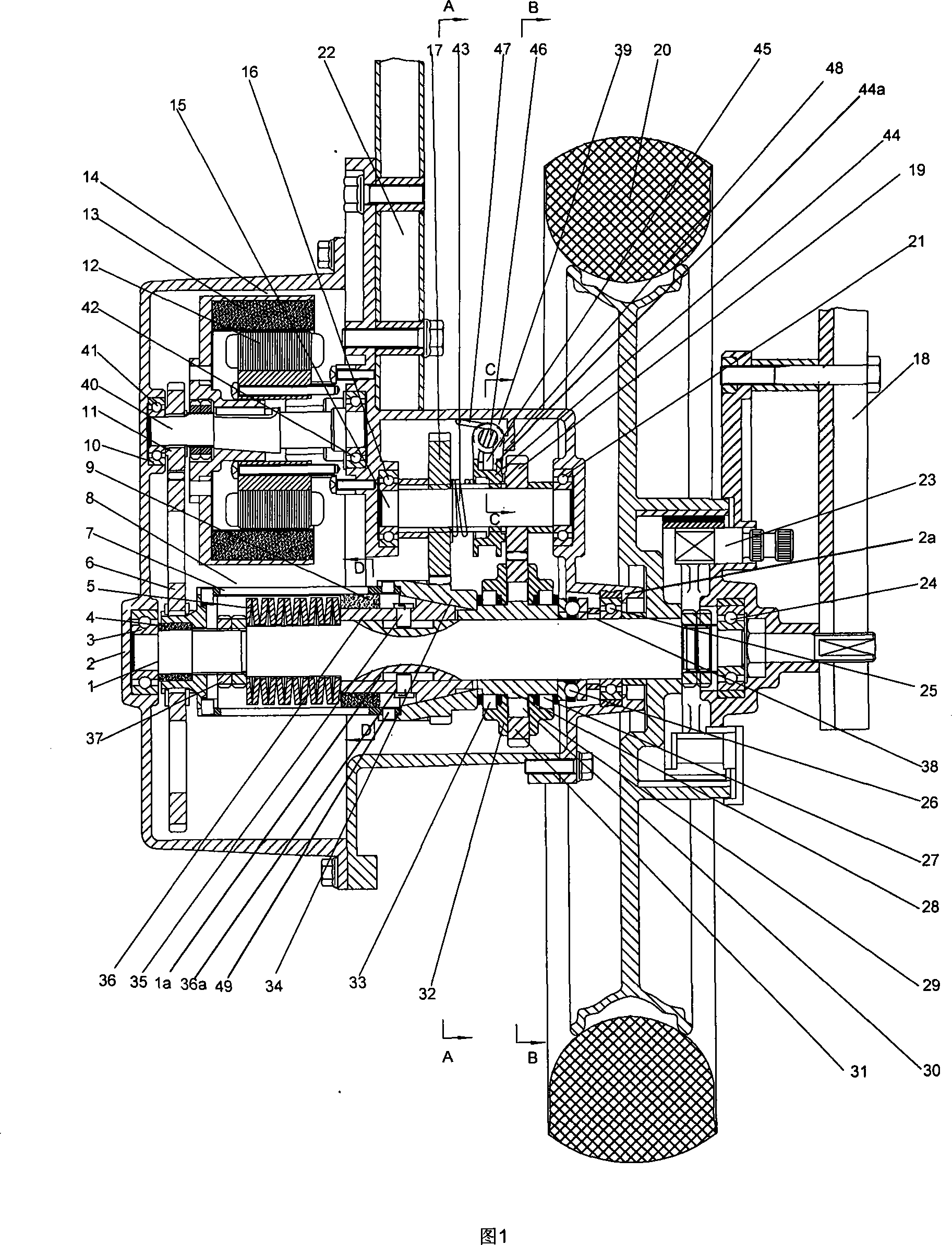

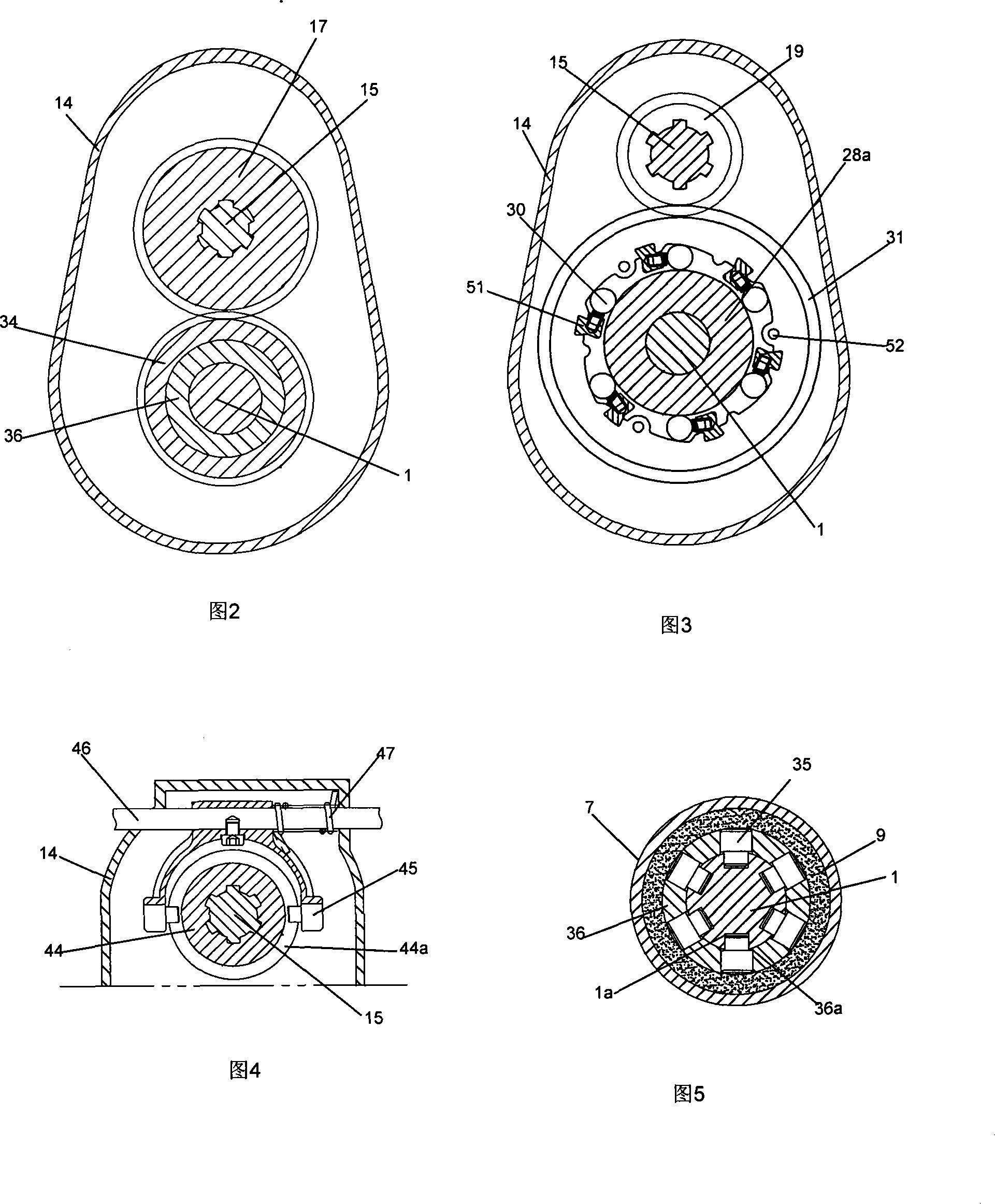

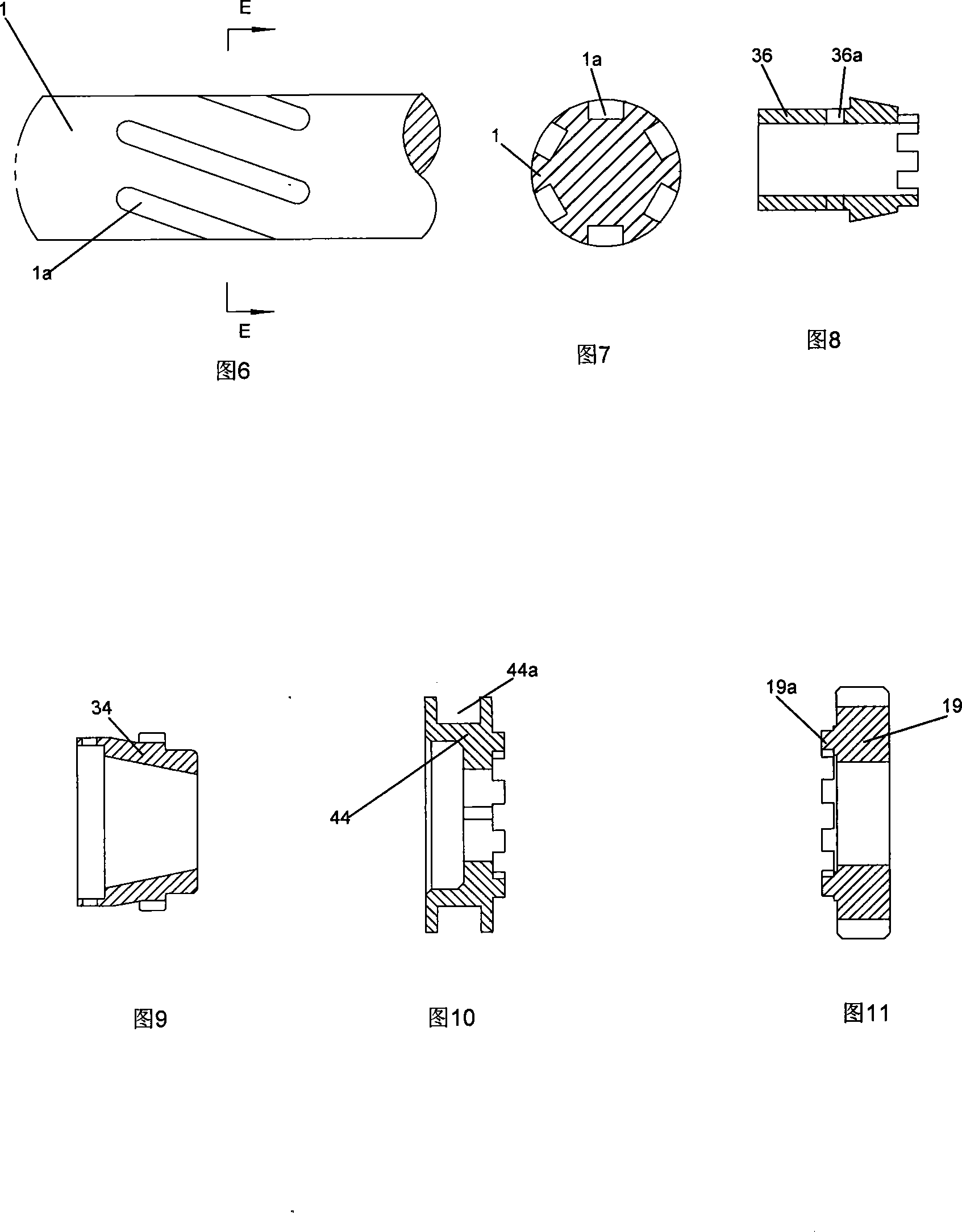

[0040] Fig. 1 is a schematic diagram of the axial section structure of the present invention, as shown in the figure: the transmission shaft 1 of this embodiment rotates counterclockwise from left to right when it is in operation, and the motor is an outer rotor motor.

[0041] The side-mounted cone-disc type self-adaptive two-speed automatic transmission hub includes a left hub frame 22, a right hub frame 18, a box body 14, a motor, a drive shaft 1, a wheel 20 and a brake device 23 arranged on the drive shaft, and the inside of the wheel 20 is The ring and the outer circle of the camshaft 1 are fixedly matched by splines, and the left hub frame 22 and the right hub frame 18 are fixedly connected with the box body 14 through fixing bolts; the box body 14 is fixedly connected with the left hub frame 22, and the brake device 23 is provided with Outer bracket, the outer bracket is fixedly connected with the right wheel hub frame 18 through a spline, the part of the camshaft 1 prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com