Method and device for on-line producing carbonic anhydride ion water

A carbon dioxide, ionized water technology, applied in the direction of adding substances to water/sewage treatment, etc., can solve the problems of reducing the gas-liquid contact area, ion concentration fluctuation of ionized water, affecting the flow of the filter, etc., to increase the gas-liquid contact area, fluid The effect of shortening the time and speeding up the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

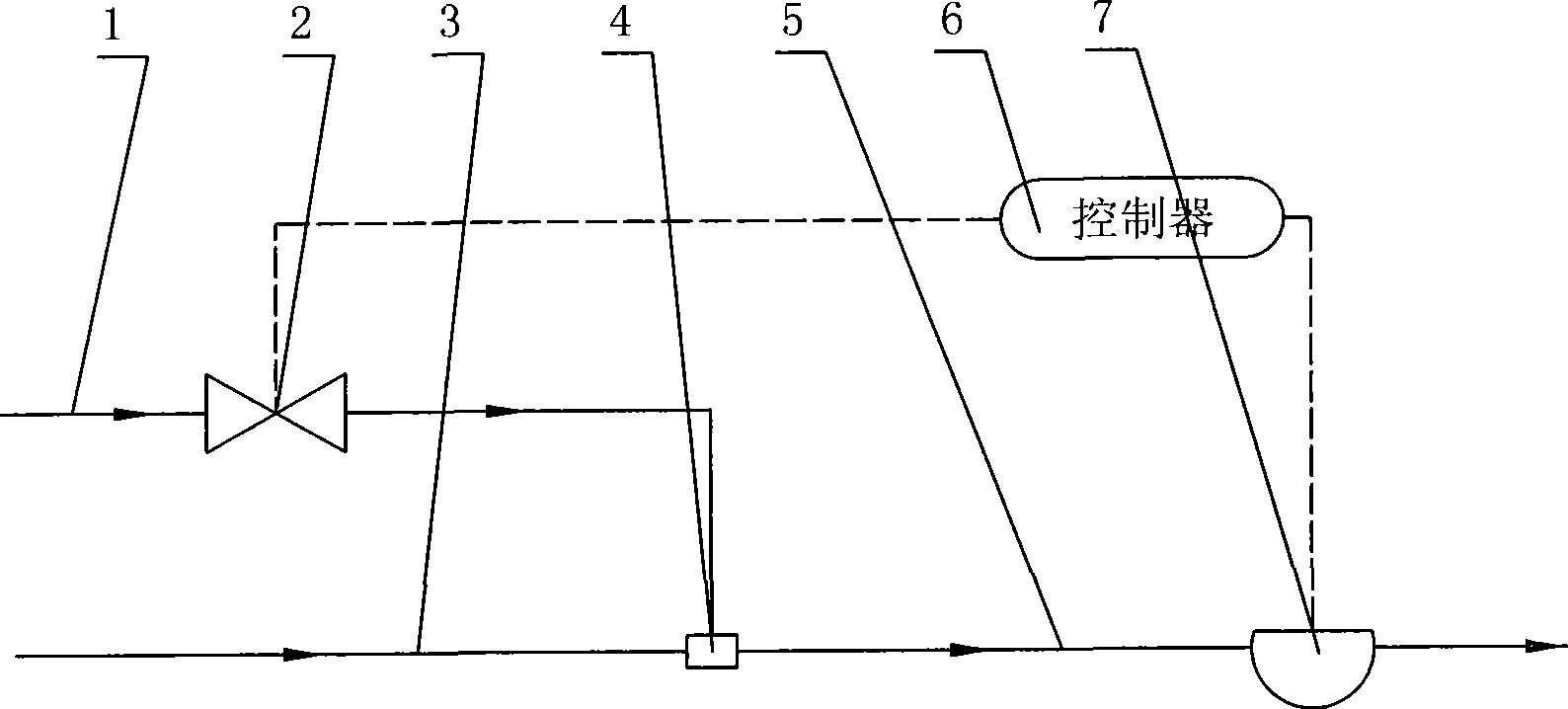

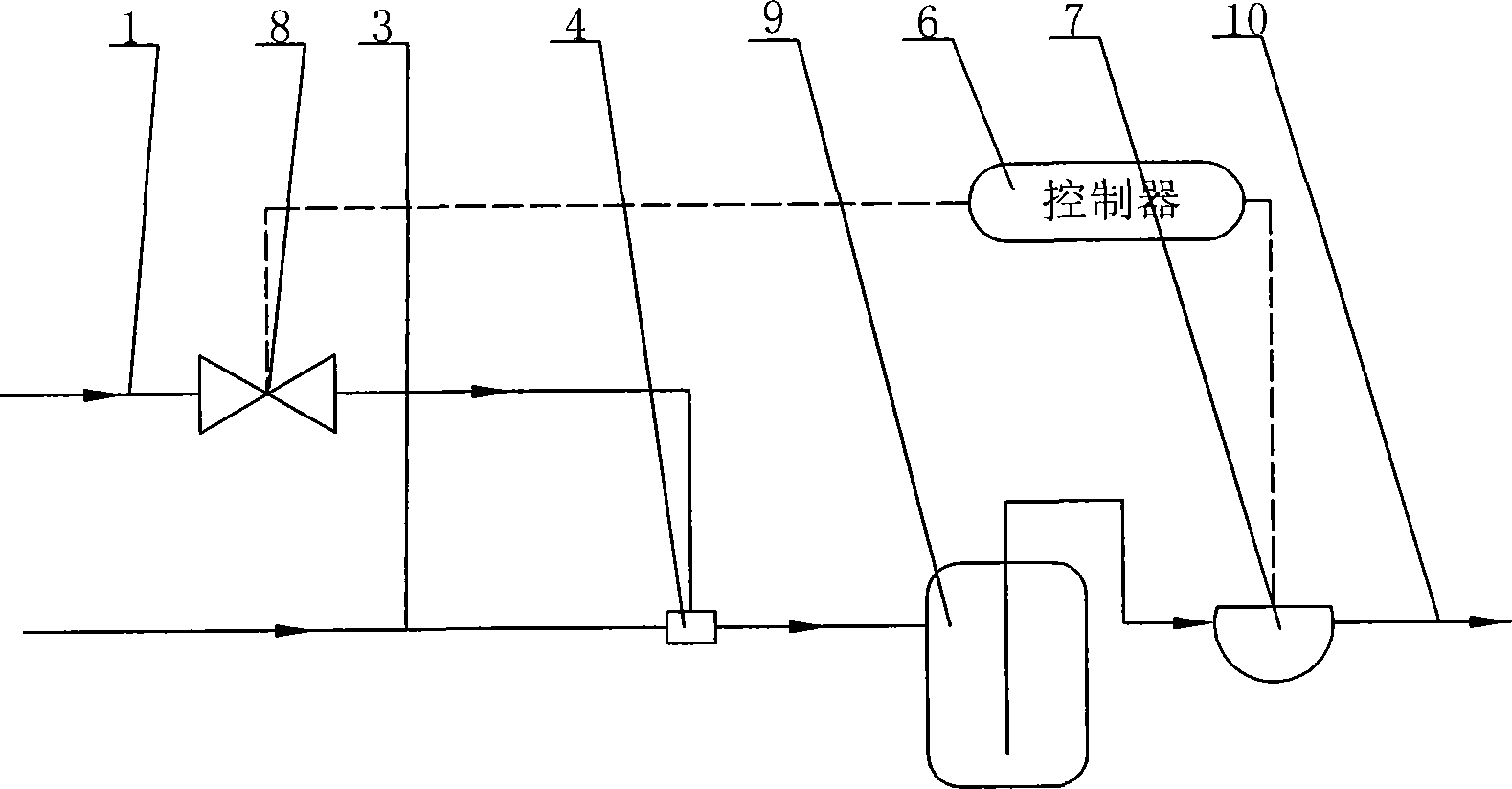

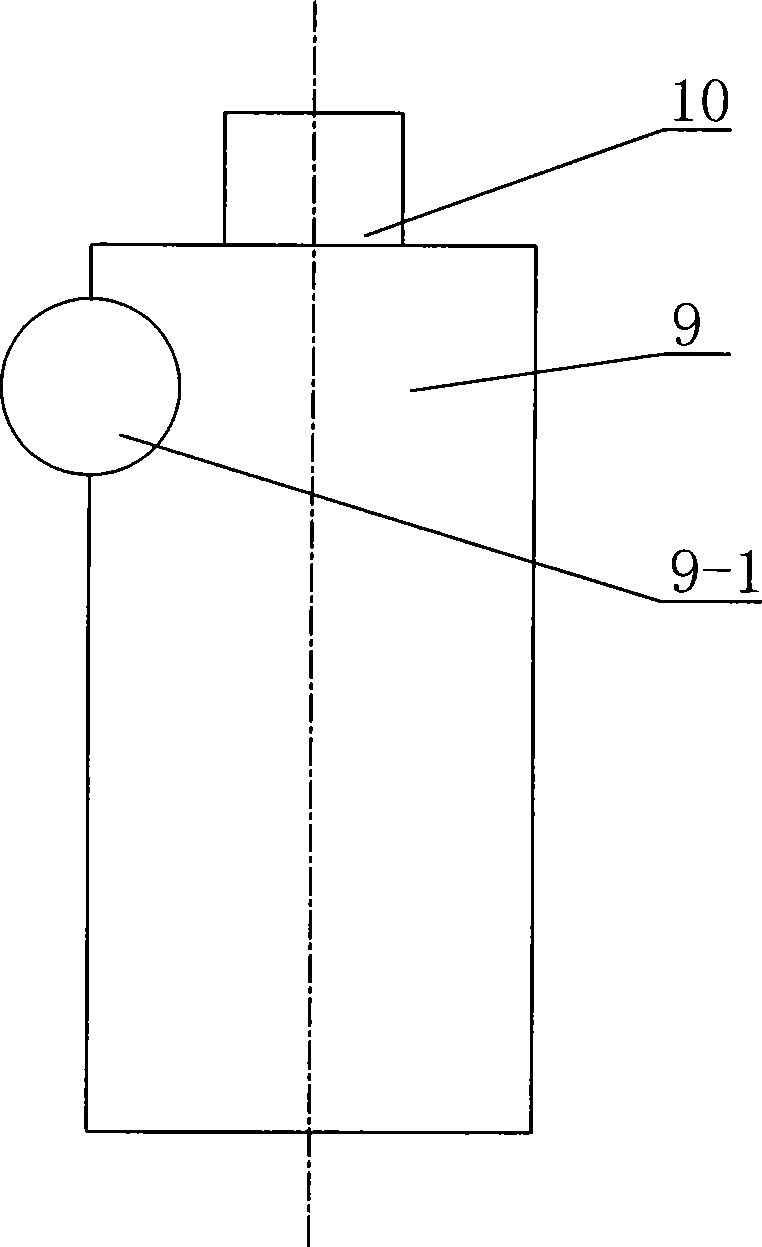

[0021] On-line preparation method of carbon dioxide ionized water of the present invention, see figure 2 As shown, carbon dioxide gas is first mixed with deionized water in the tee pipe after passing through the pressure regulating valve, and then the mixture enters the mixing cylinder tangentially at a speed greater than 15ml / s, and the mixture forms a spiral vortex in the mixing chamber of the mixing cylinder , the bubbles in the mixture are broken up under the action of centrifugal force, and the carbon dioxide gas is dissolved into the deionized water to form ionized water, which is sent out to the designated point through the outlet pipe, and the conductivity probe detects the conductivity of the ionized water, and the The data is input into the controller and compared with the set conductivity, the controller outputs an adjustment signal according to the difference between the two conductivity, adjusts the opening of the pressure regulating valve, adjusts the inflow pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com