Biological diesel oil and method of manufacturing the same

A technology of biodiesel and raw oil, applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, biofuels, etc., can solve problems such as environmental pollution, and achieve the effect of reducing emissions and reducing carcinogenic rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The acidified rapeseed oil of 1000 kilograms of edible oil production plants is heated to 70 ℃ and then adds the aluminum sulfate of 1% by weight of raw material oil ester weight and is 30% aluminum sulfate, stirs 30 minutes, static precipitation 24 hours, collects supernatant liquid, and deposit can For biological fertilizer, the supernatant is filtered to remove impurities to obtain relatively pure raw materials.

[0019] Put the above-mentioned 1000 kilograms of pretreated raw oil esters, 150 kilograms of methanol and 10 kilograms of sodium formate into the heating kettle, stir and react, the stirring speed is 30 revolutions / min, the reaction temperature is 65 ° C, reflux for 1 hour, and then Stand still for 1 hour to separate layers, discharge acid water, reclaim methanol, wash with water, and obtain crude methyl ester with a weight of 95%;

[0020] Then add 1 kg of boric acid, stir evenly, pump into the distillation kettle to heat up to 220°C, and the vacuum degree...

Embodiment 2

[0024] Put 800 kg of roast duck oil, 120 kg of methanol and 4 kg of sodium formate into the esterification kettle, heat it to 70°C under normal pressure, reflux for 2 hours, and recover excess methanol by steaming. After the reaction, stand still for 1.5 After 1 hour, discharge the acidic water, then wash with water to obtain 760kg of crude methyl ester, then add 0.8kg of boric acid, stir evenly, pump it into the distillation kettle and heat it to 220 ° C ~ 280 ° C, and distill it under the condition of a vacuum of 0.09 MPa to obtain 684 kg of biodiesel.

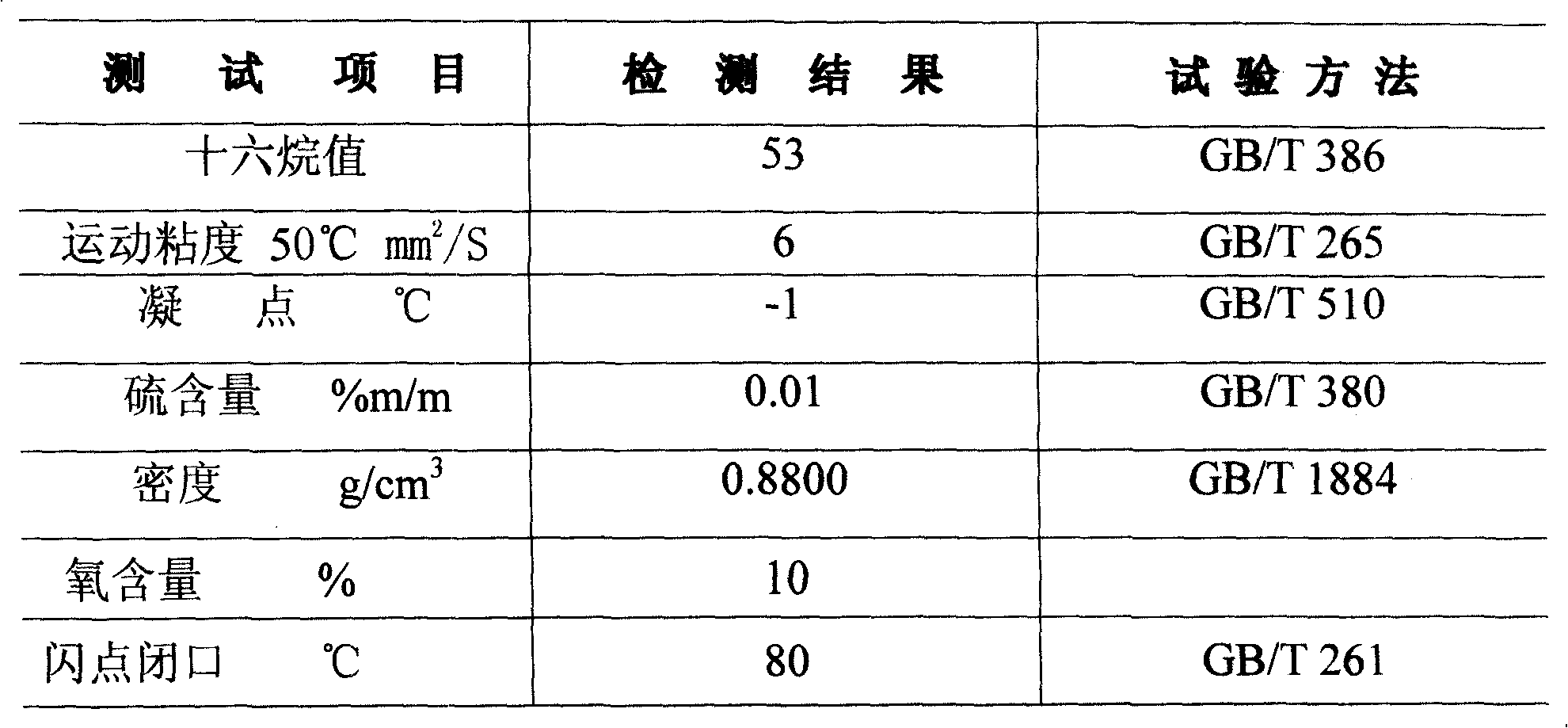

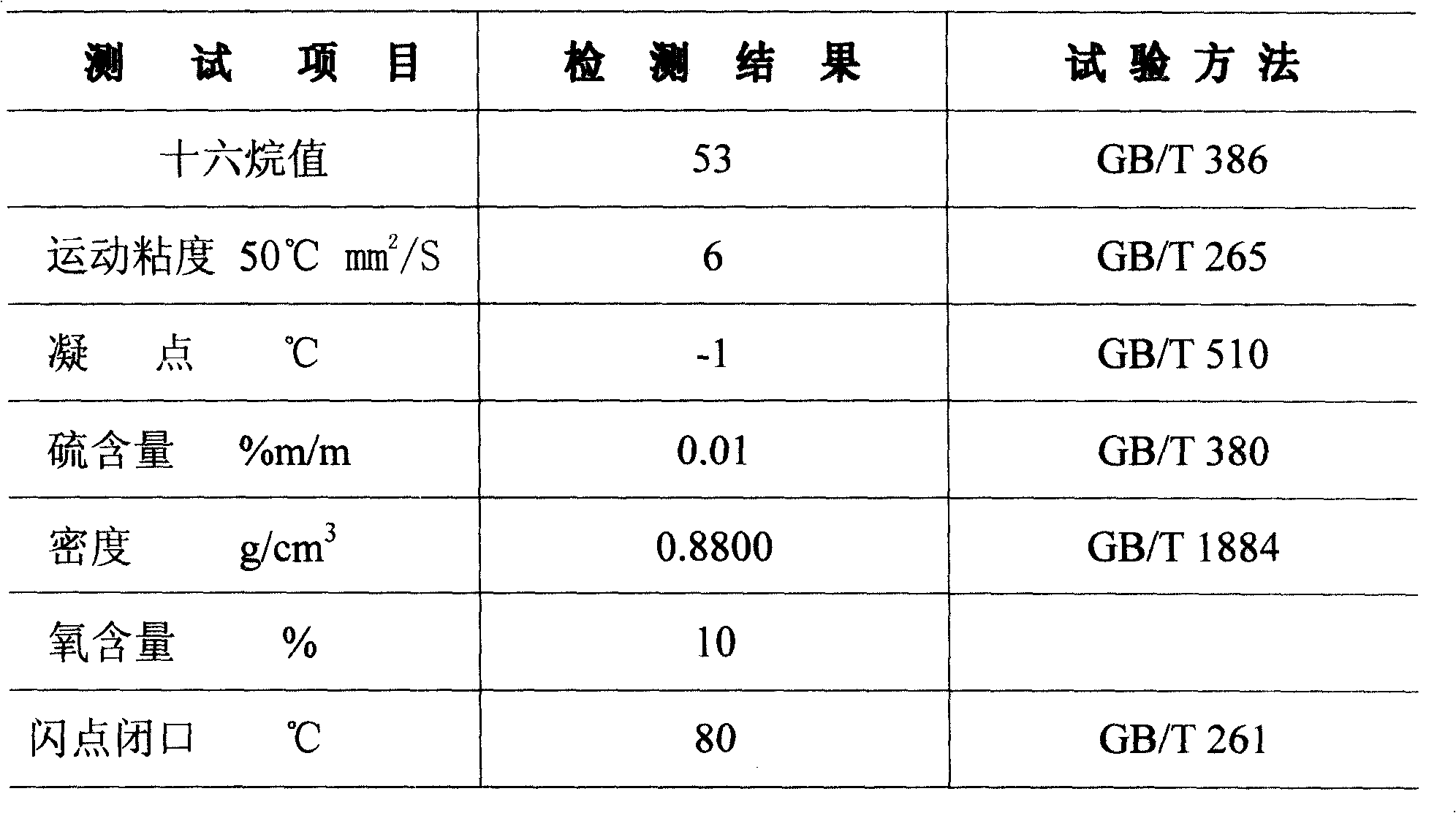

[0025] Refer to GB / T17411~1998, ISO 8217:1996 standard for detection and testing, the test results are as follows:

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com