Solid base catalyst and applications for preparing biological diesel oil

A technology of solid base catalyst and biodiesel, which is applied in molecular sieve catalysts, physical/chemical process catalysts, biofuels, etc., can solve the problems of time and energy consumption, waste of raw materials, etc., and achieve no environmental pollution, less energy consumption, and high productivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Preparation of the 1st step solid base catalyst

[0017] Put 6g of potassium acetate and 10g of alumina in a mortar, grind at room temperature for about 1 hour, and then roast in a muffle furnace at 500°C for 5 hours to obtain the product.

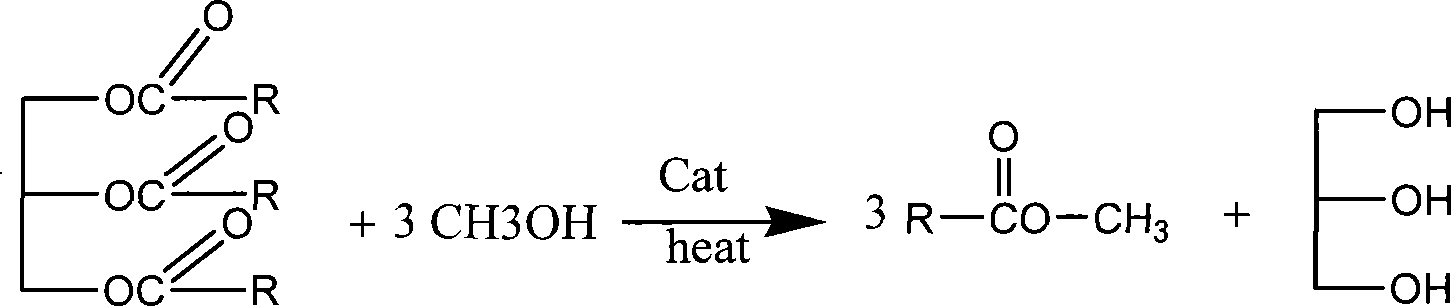

[0018] Step 2 transesterification reaction

[0019] Add 5g of rapeseed oil, 1.5g of methanol, and 0.1g of the above-mentioned solid base catalyst into a 100mL three-necked flask equipped with electromagnetic stirring, a thermometer, and a reflux condenser, heat under reflux and stir for 2 hours, and heat to 90°C.

[0020] Step 3 Separation of catalyst and purification of product

[0021] Filter the reacted material in the three-necked bottle, the filtered catalyst can be directly used for the next reaction, the filtrate is separated to separate the lower layer of glycerin, and the upper layer product is added with 6% NaHCO 3 Solution 70ml washes to neutrality, to remove unreacted free fatty acid, separates the upper layer organic ...

Embodiment 2-6

[0023] Except following difference, all the other are identical with embodiment 1, and in the process of preparing catalyst, methyl acetate is by the consumption of table 1.

[0024] Table 1

[0025]

Embodiment 7-15

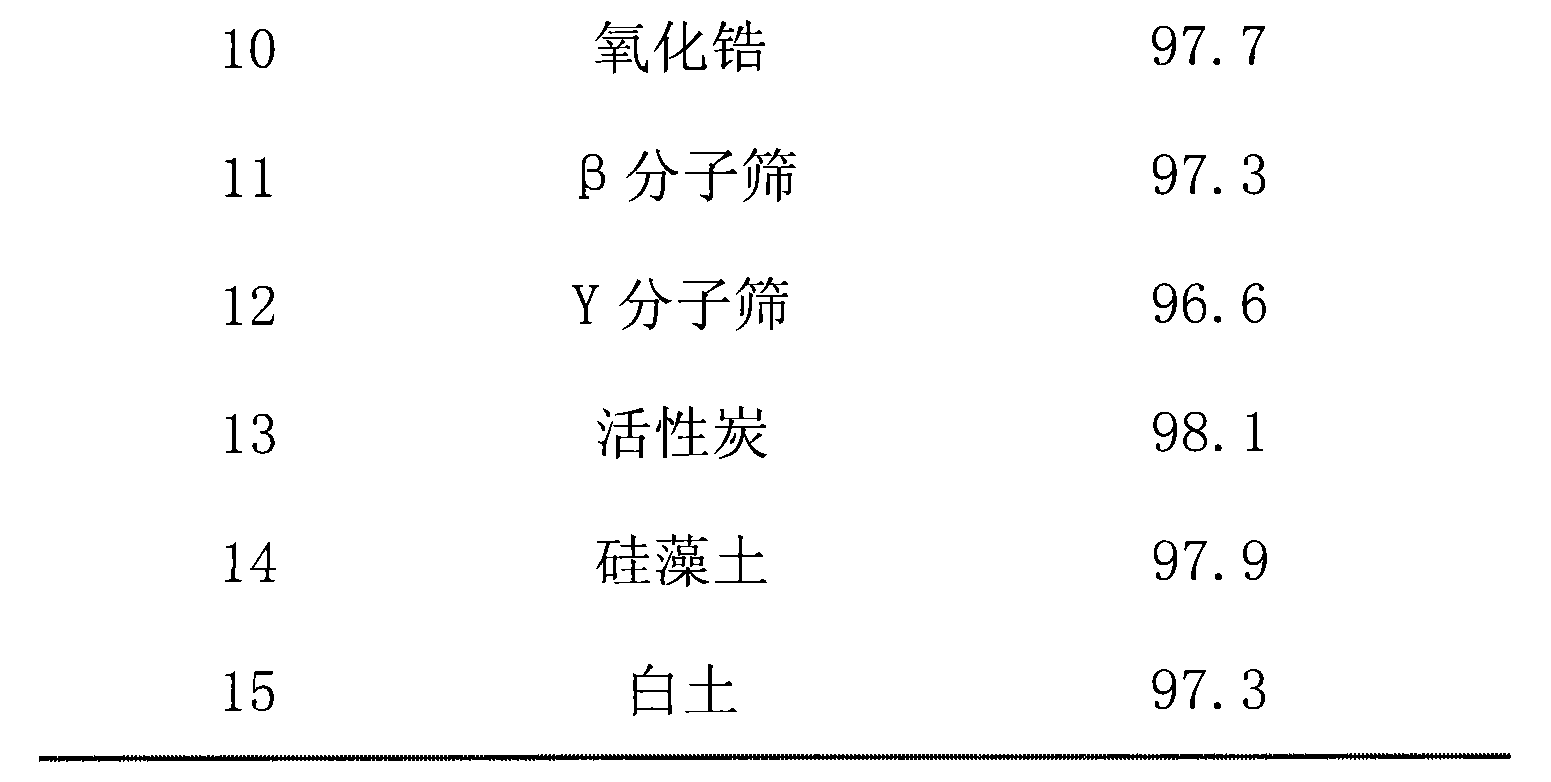

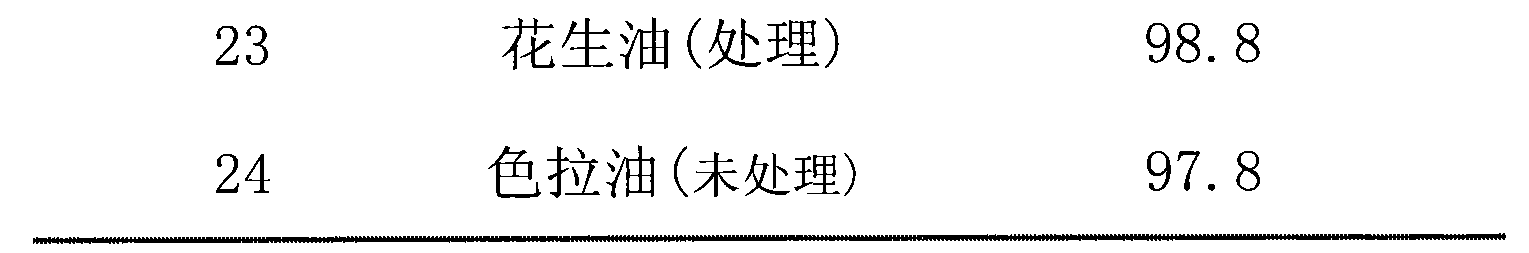

[0027] Except for the following differences, the others are the same as in Example 1, and the carriers shown in Table 2 are used respectively.

[0028] Table 2

[0029]

[0030]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap