Thermal isolation micro-bridge structure and processing method thereof

A technology of micro-bridge structure and thermal insulation is applied in the field of micro-bridge structure with enhanced thermal insulation and its processing, and in the field of sensors using thermal-insulation micro-bridge structure, which can solve the problems of decreased filling factor and complicated process, and improve thermal insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

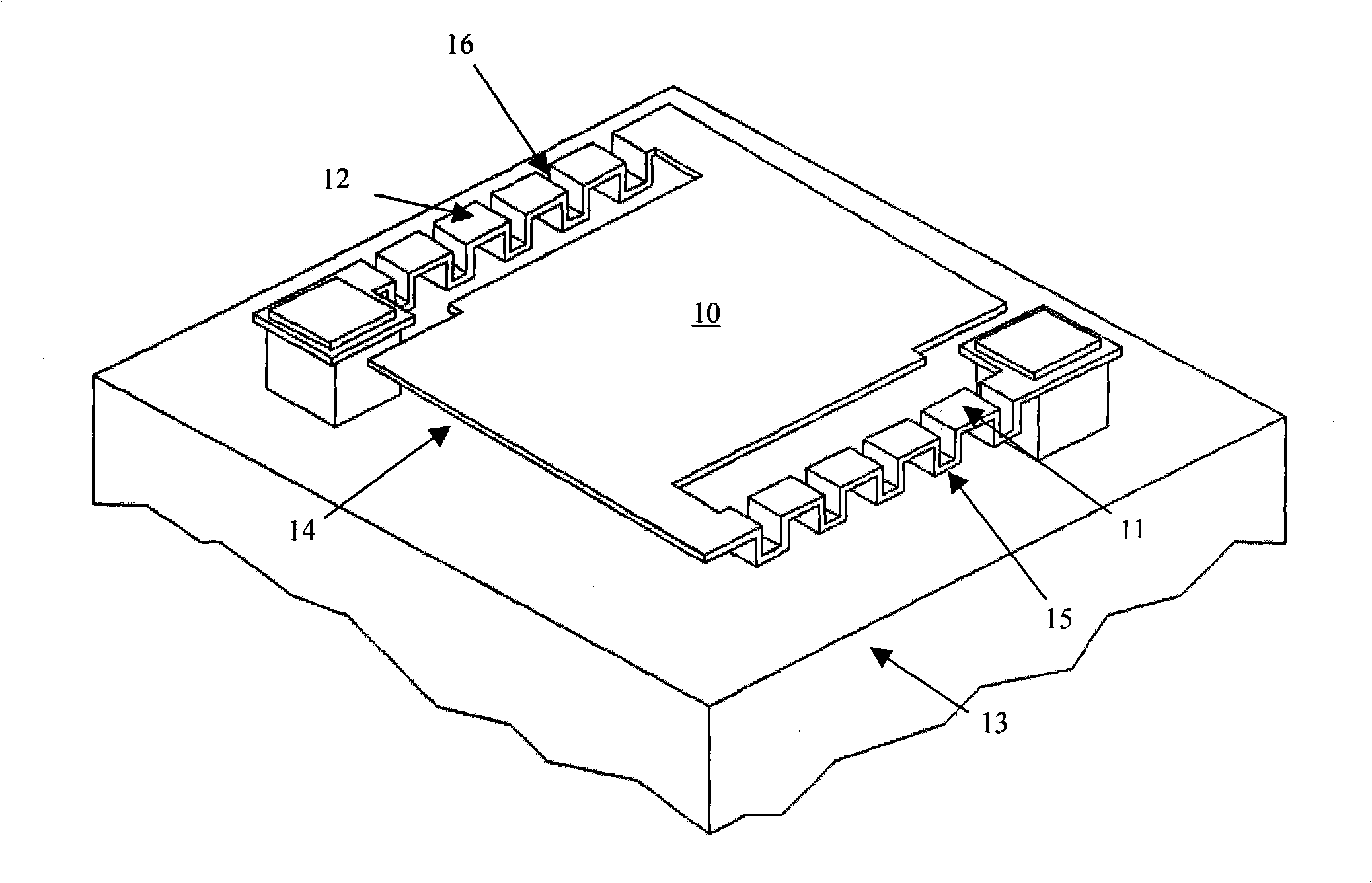

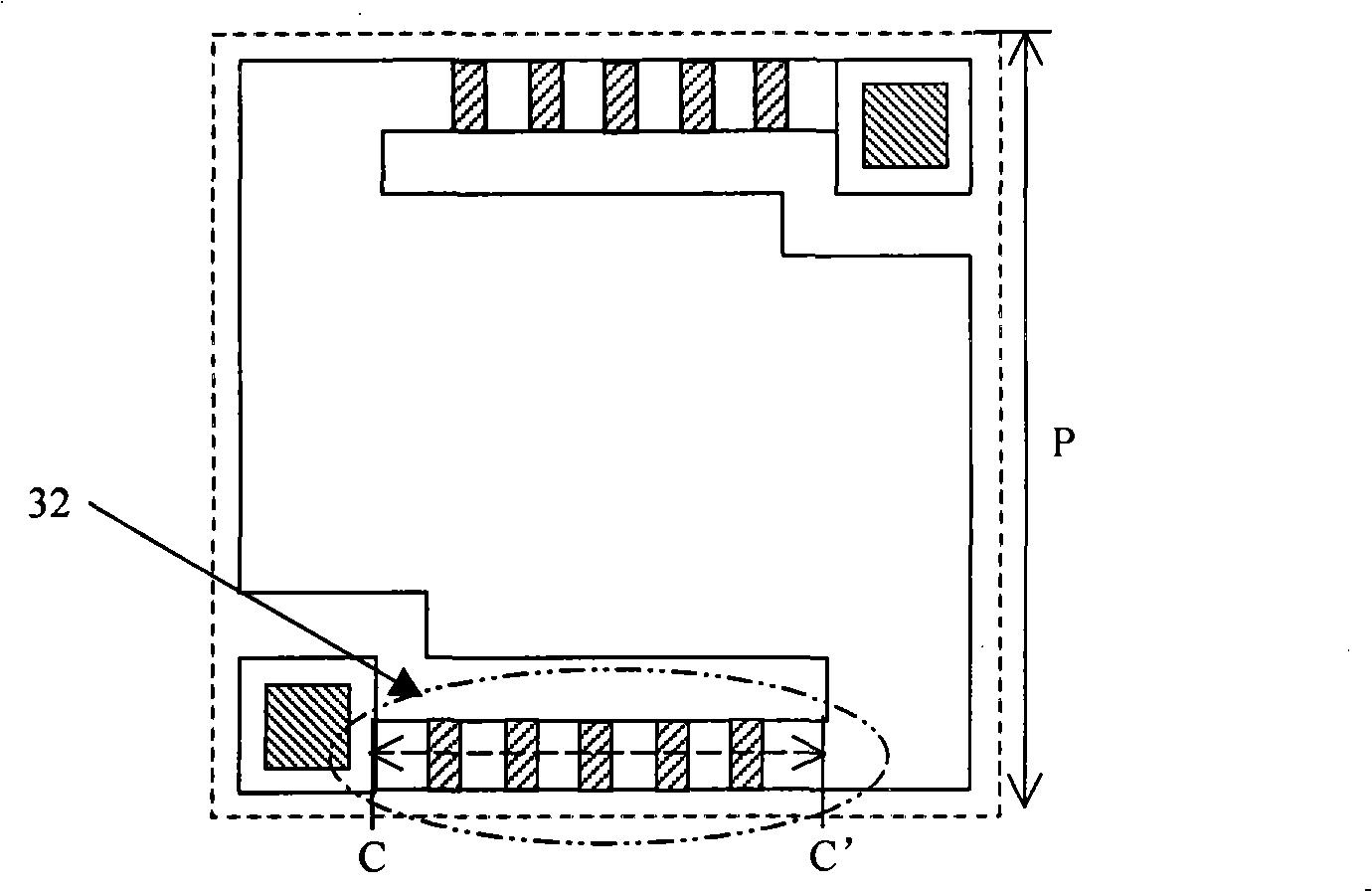

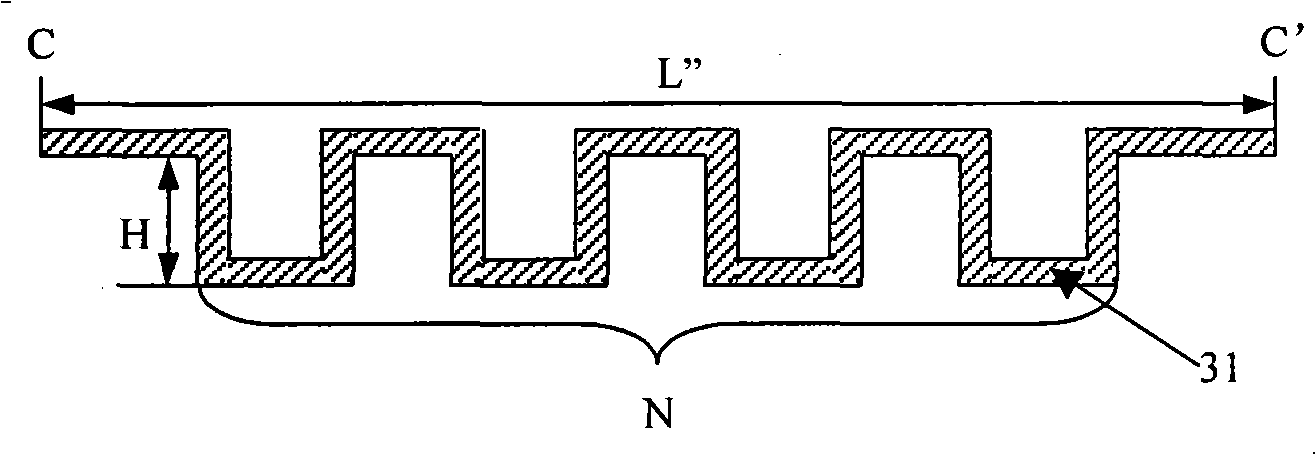

[0052] Such as Figure 4 shown. In an uncooled infrared detector, a typical application example of a microbridge structure, in order to absorb radiation energy to the greatest extent, the distance between the microbridge and the substrate surface is usually required to meet a quarter of the wavelength of the incident radiation. Under this condition, the radiation reflected from the substrate surface coherently interferes with the incident radiation and facilitates the absorption of the incident radiation by the microbridges. The distance between the microbridge and the substrate surface is determined by the thickness of the sacrificial layer of the micromachining process. Typically, uncooled infrared detectors detect infrared radiation around 10 microns. The distance between the corresponding microbridge and the substrate surface is required to be about 2 microns. Therefore, the sidewall height (H) of the corrugated structure cannot exceed the thickness of the sacrificial l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com