Insulation explosion-proof bolt

A technology of explosion-proof bolts and bolts, applied in the directions of screws, threaded fasteners, pressure vessels, etc., can solve the problems of unfixable position, complicated construction, explosion of pressure vessels, etc., to shorten construction and downtime, avoid explosion accidents, and easily effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

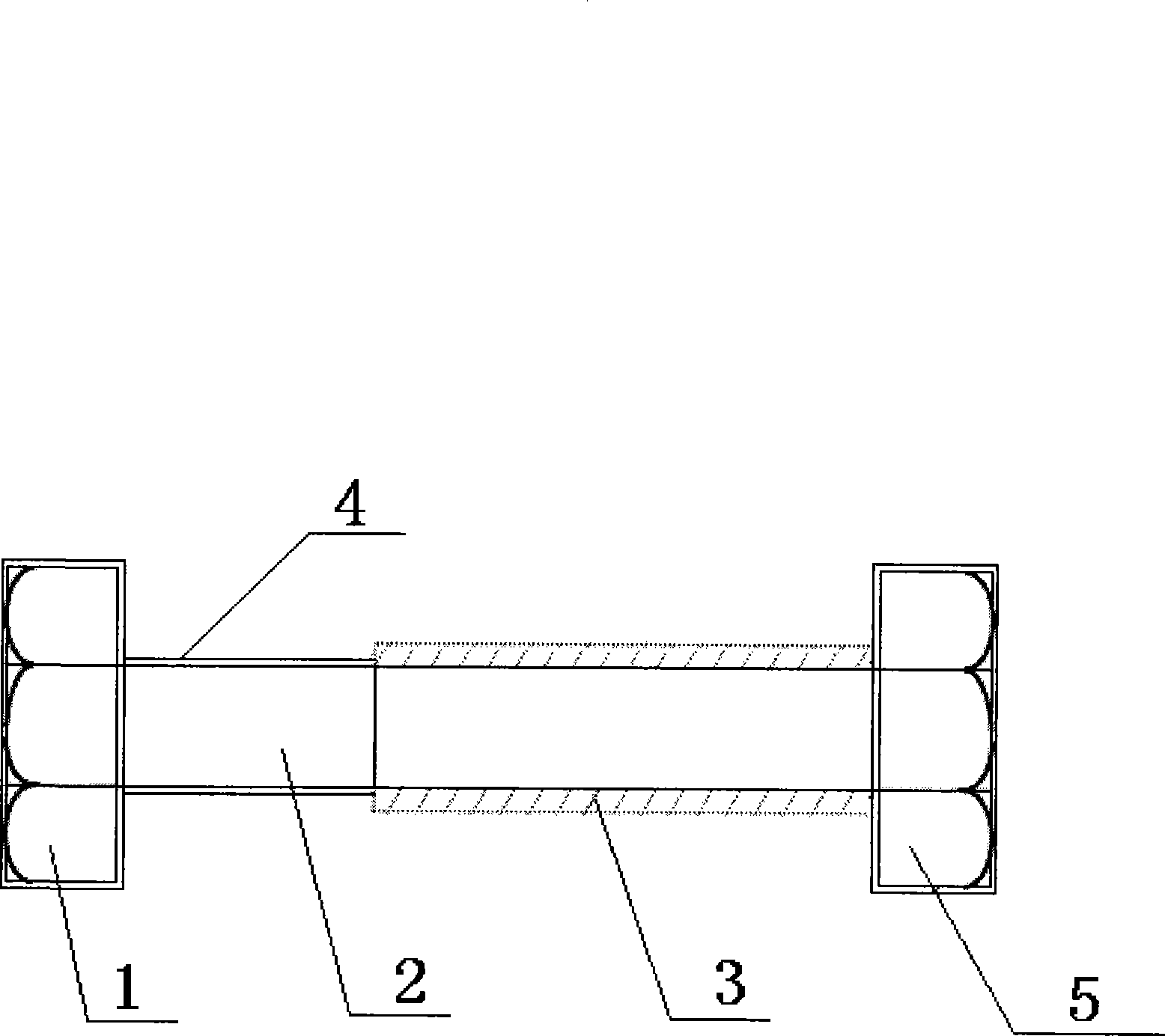

[0008] combined with figure 1 , to further describe the present invention, its technical solution is: the shape refers to the existing metal bolts, including bolt 2, fixed nut 1, movable nut 5 and thread 3, described bolt 2, fixed nut 1, movable nut 5 and The outer layer of the thread 3 is provided with an insulating layer 4, in order to enhance its bearing capacity, the thread 3 is made into a trapezoidal thread, wherein the insulating layer 4 is a hard plastic layer. Certainly, the present invention also can adopt hard plastic to make directly.

[0009] The method of use is: replace the original metal bolts with the present invention before using electric welding, use gas to dry the liquid on the insulating explosion-proof bolts, and keep them dry, because the material is plastic, the insulation performance is high, and the flanges are sealed, the pressure Static sparks will not be generated in the container, and the construction position is also fixed,

[0010] The specif...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap