Leadless cadmium-free reinforced glass pigment flux

A technology for tempered glass and pigment, applied in the field of lead-free and cadmium-free tempered glass pigment flux, can solve the problems of human health hazards, environmental pollution, hazards, etc., and achieve the effects of pure color, wide adaptability and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

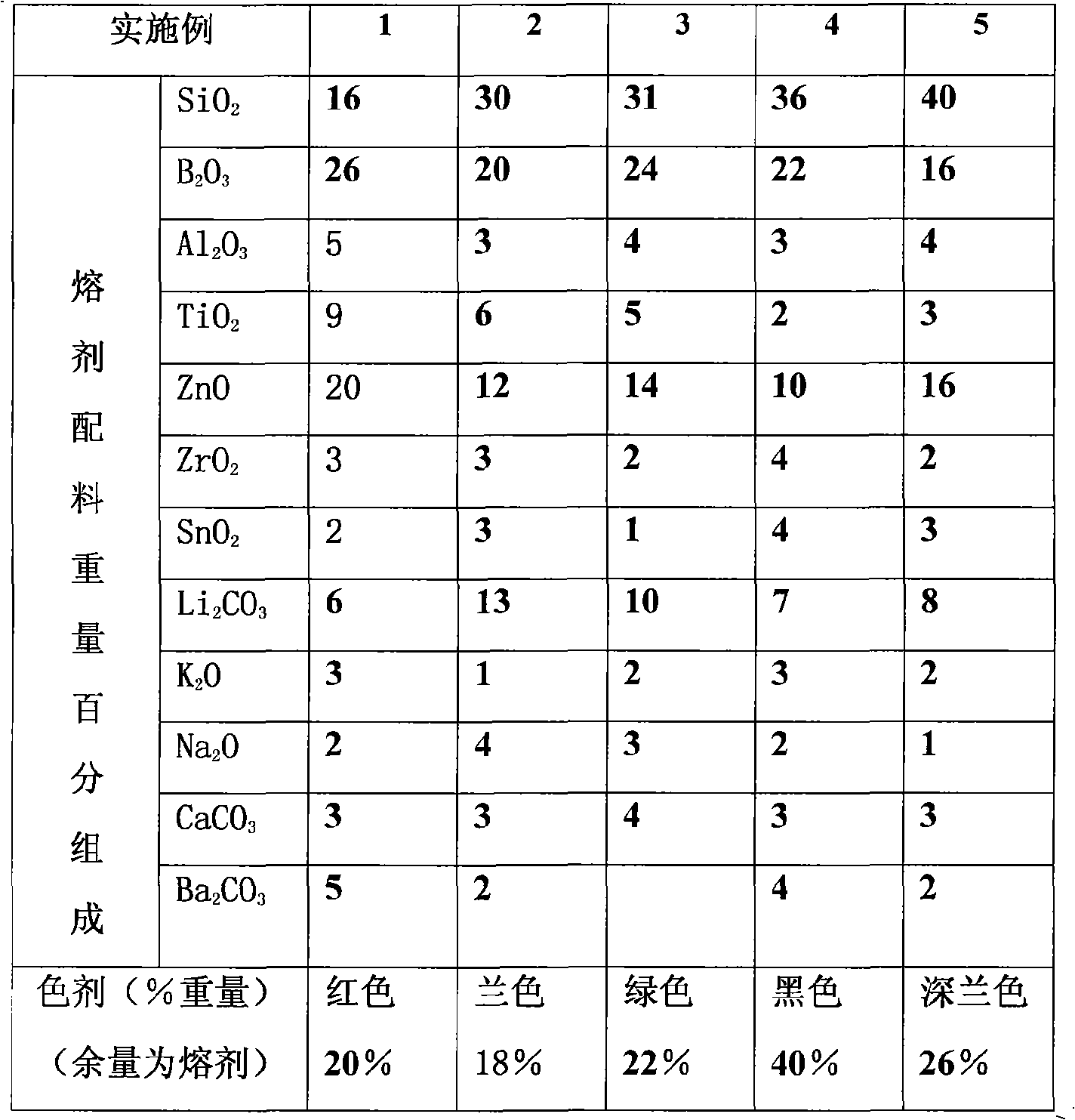

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment.

[0022] The preparation method of the tempered glass pigment in the embodiment is to prepare the flux first, and then prepare the pigment according to the composition ingredients, and the steps are as follows:

[0023] ①Preparation of flux: Mix the raw materials required for the solvent evenly in proportion, quench in molten water at a temperature of 1260±20°C, and dry for later use;

[0024] ②Ball milling: Put the flux and black agent or white agent in proportion to the ball mill until the particle size is less than 80 microns, and dry it for later use;

[0025] ③ Re-burning: the ball-milled mixture is re-fired and water-quenched at a temperature of 750±20°C;

[0026] ④Secondary grinding: put the water-quenched material after reburning into a ball mill for wet grinding until the particle size is less than 5 microns, after grinding, drying and crushing, the finished pigment can be ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com