Leadless piezoelectric ceramics/polymer 1-3 structure composite material and method for processing same

A composite material and piezoelectric ceramic technology, applied in the field of lead-free piezoelectric ceramic/polymer 1-3 structure composite material and its processing, can solve the problems of high brittleness of piezoelectric ceramics and difficult mechanical micro-processing, and achieve brittleness Large, strong and tough, easy to prepare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

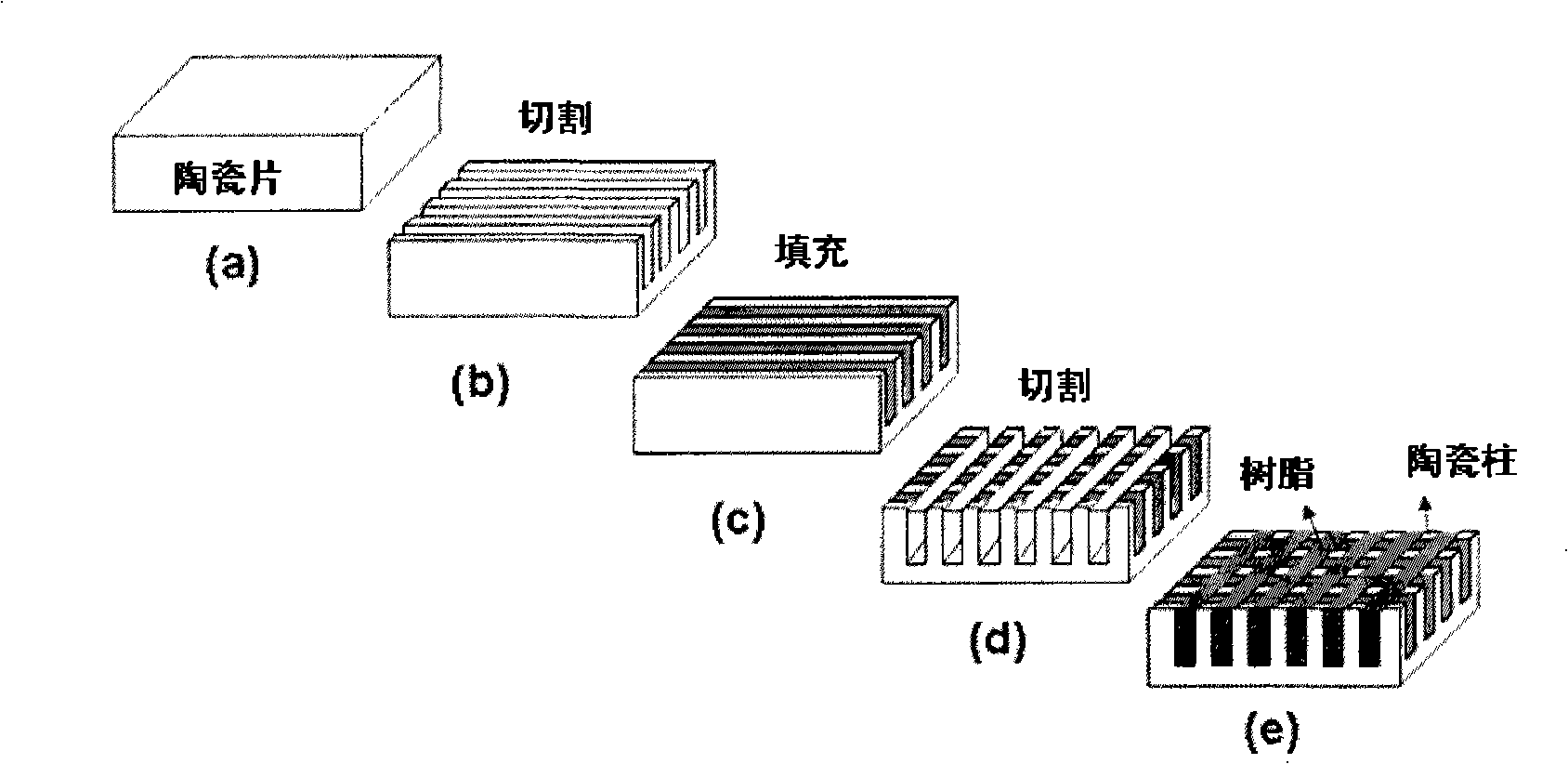

Embodiment 1

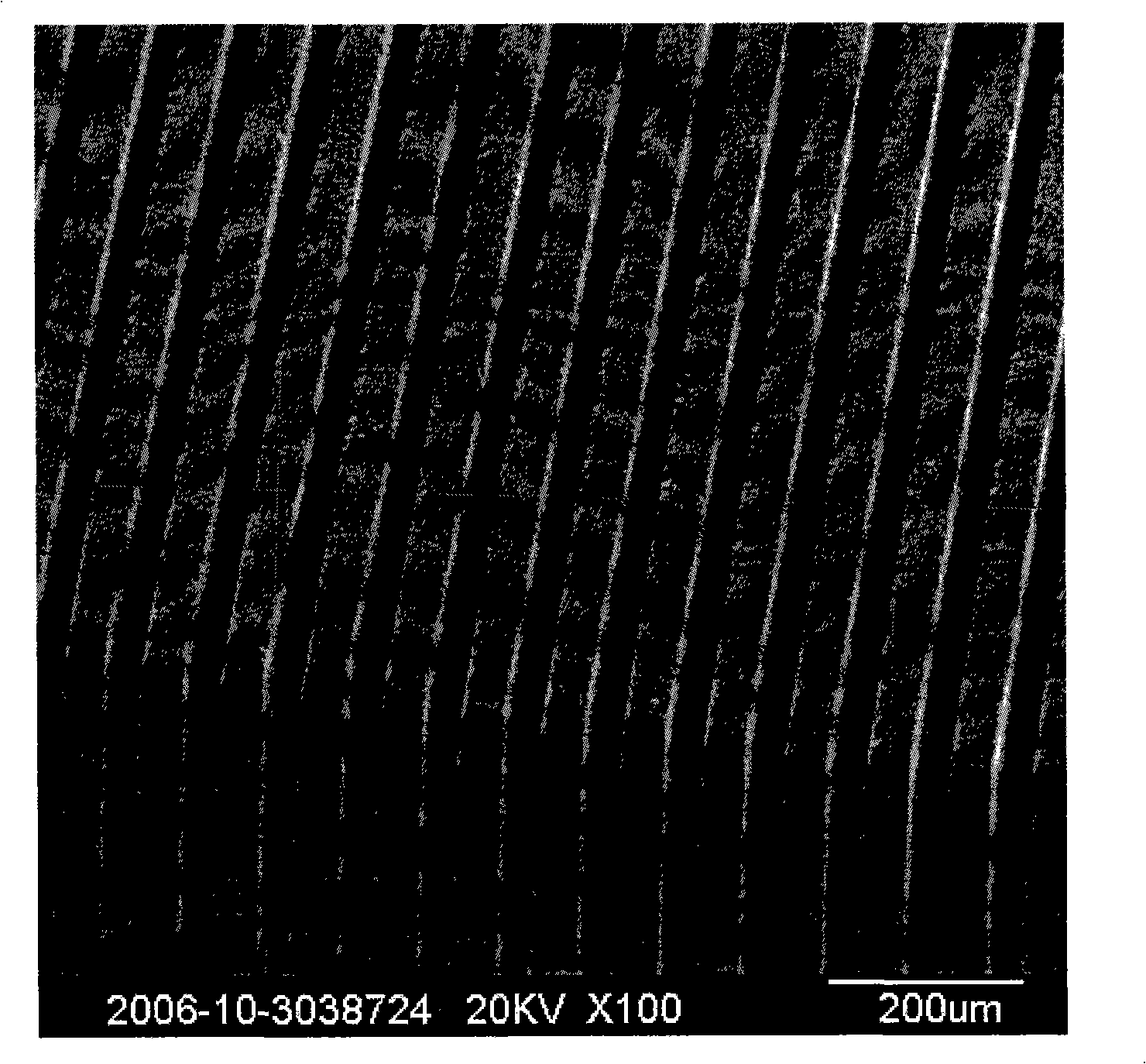

[0030] According to (Li 0.04 K 0.44 Na 0.52 )(Nb 0.85 Ta 0.15 )O 3 Proportioning of raw materials, using normal pressure sintering process at 1100 degrees for 2 hours to obtain ceramic samples, the size of which is: diameter 10mm, thickness 3mm. Use 800# corundum sandpaper to smooth both sides and fix it on the sample stage of a diamond automatic scribing machine (developed by Shenyang Academy of Instrumentation, model ZSH-3), and then use a diamond blade with a thickness of 32um to cut at a rate of 1mm / s Cutting at a high speed, the cutting depth is about 0.2mm. figure 2 This is the photo of the sample obtained after parallel cutting, and the intact thin slice array sample is obtained. The width of the cut is about 40um, slightly wider than the thickness of the blade due to slight vibration and wear.

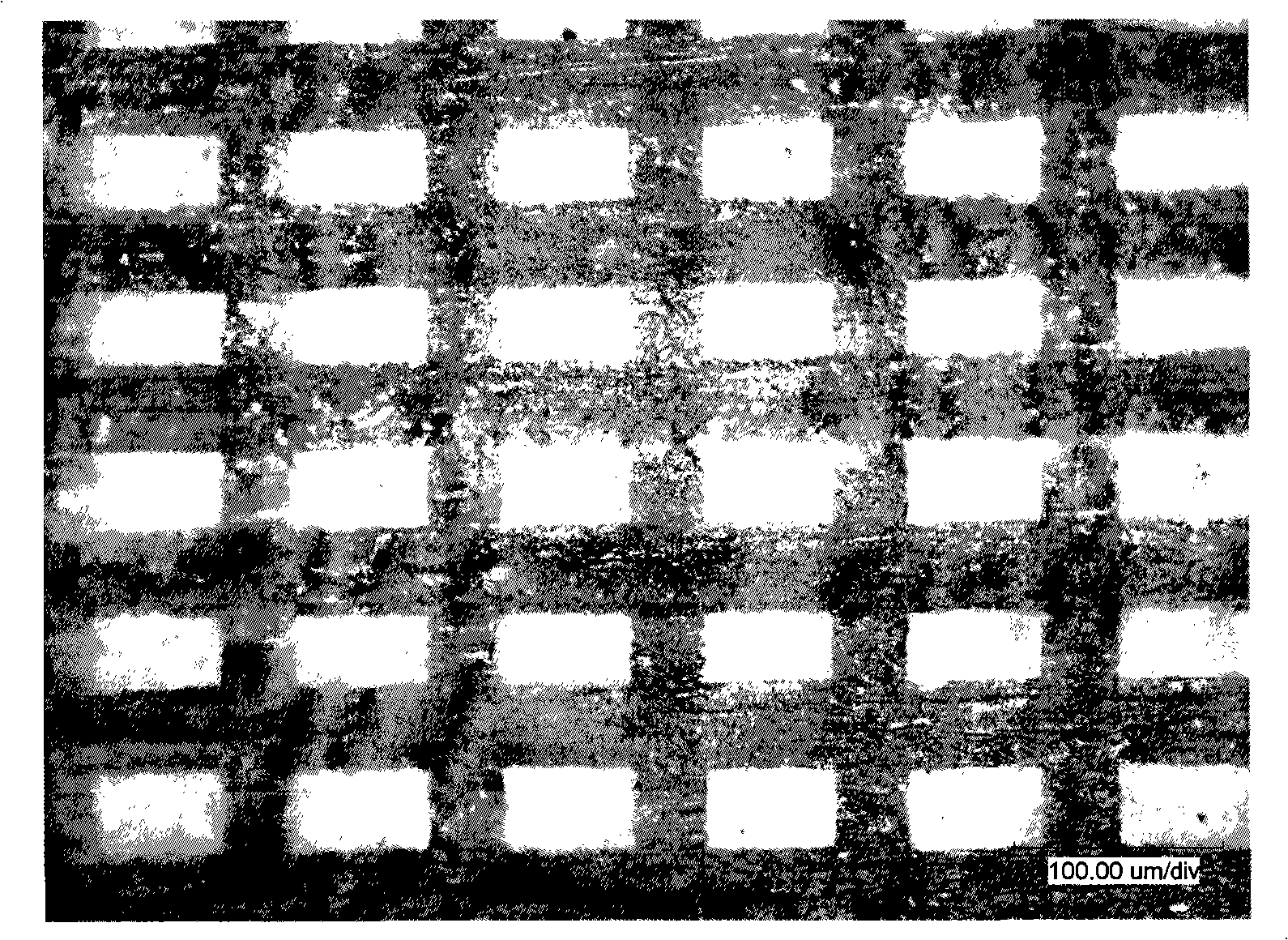

[0031] Then, epoxy resin (manufactured by Bushler, USA, mass ratio of resin / curing agent: 100:36) was coated on the surface of the incision sample, so that the resin wa...

Embodiment 2

[0033] Using the ceramic sample obtained in Example 1 and a diamond automatic scribing machine, cut under the same conditions. According to the conventional cutting method (the prior art), after the first parallel cutting, the sample is not filled with resin, and the sample is directly rotated by 90 degrees before the second parallel cutting is performed. Since the ceramic pillars are not supported by the resin, they almost completely collapse, and the ceramic pillar array structure cannot be obtained.

Embodiment 3

[0035] Using the ceramic sample obtained in Example 1 and a diamond automatic scribing machine, cut under the same conditions. Since the ceramic blades used in Example 2 were too thin and the ceramic columns were too thin, attempts were made to widen the spacing of the ceramic columns and the size of the ceramic columns. Use a diamond blade with a thickness of 50um and a ceramic column spacing of 60um. After parallel cutting, there is no resin filling, and the second parallel cutting is directly performed. Figure 6 It is a photo of the processed sample, although the processing fineness is much lower than that of Example 1, there is still the collapse of microcolumns in the sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com