Window material for silicon based thin film solar battery and preparing method thereof

A silicon-based thin film, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., to achieve the effect of easy process transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0032] The present invention is aimed at microcrystalline silicon or nano-silicon-based thin-film solar cells where sunlight is incident from the N direction of the solar cell, and proposes key N-type window materials in the structure of silicon-based thin-film cells and its preparation method. The specific implementation methods are as follows:

[0033] Prepare silicon-based thin-film solar cells on substrates by using plasma-enhanced chemical vapor deposition (PECVD), hot-wire chemical vapor deposition (HW-CVD), very high-frequency plasma-enhanced chemical vapor deposition (VHF-PECVD) and other deposition methods .

Embodiment

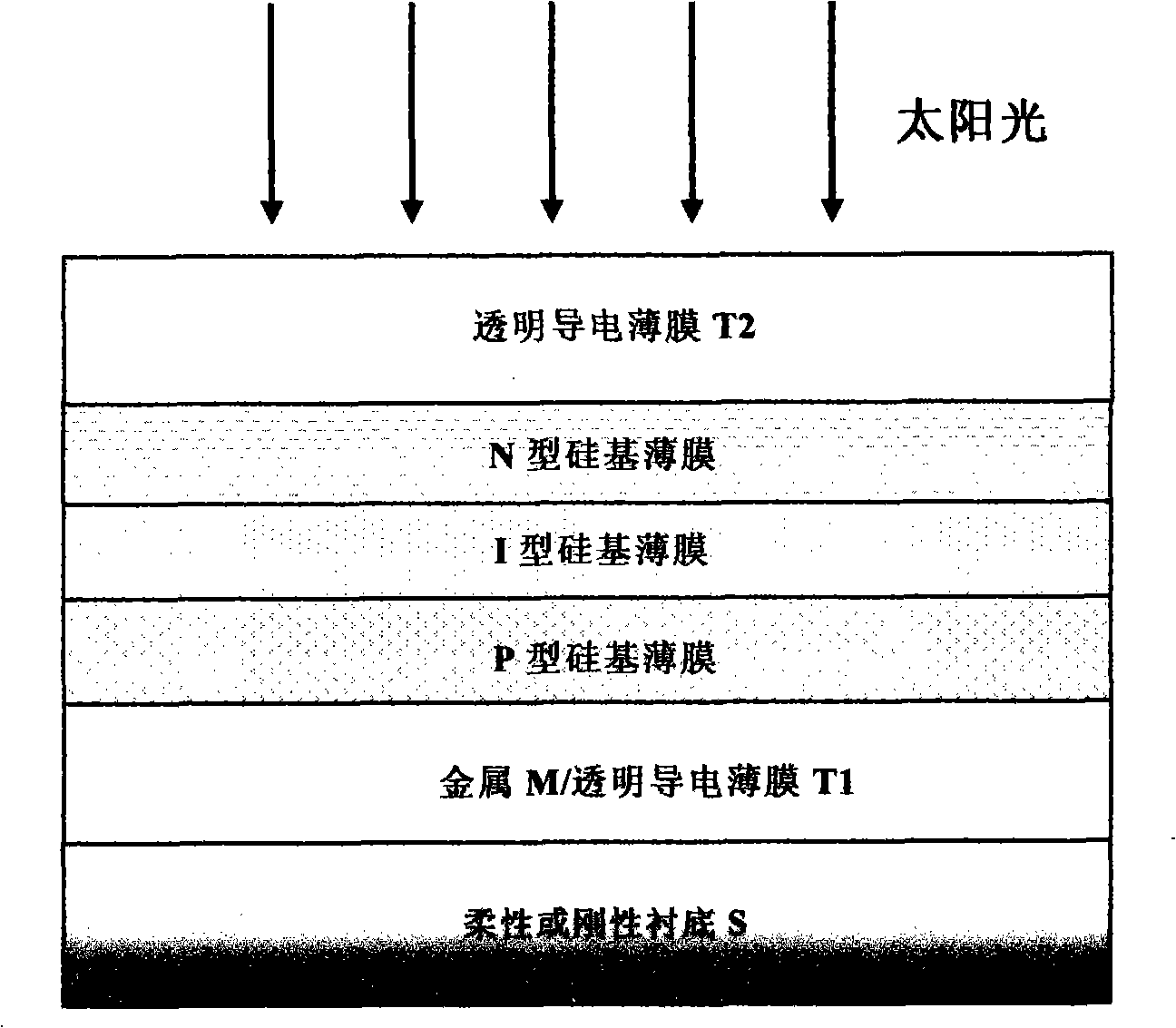

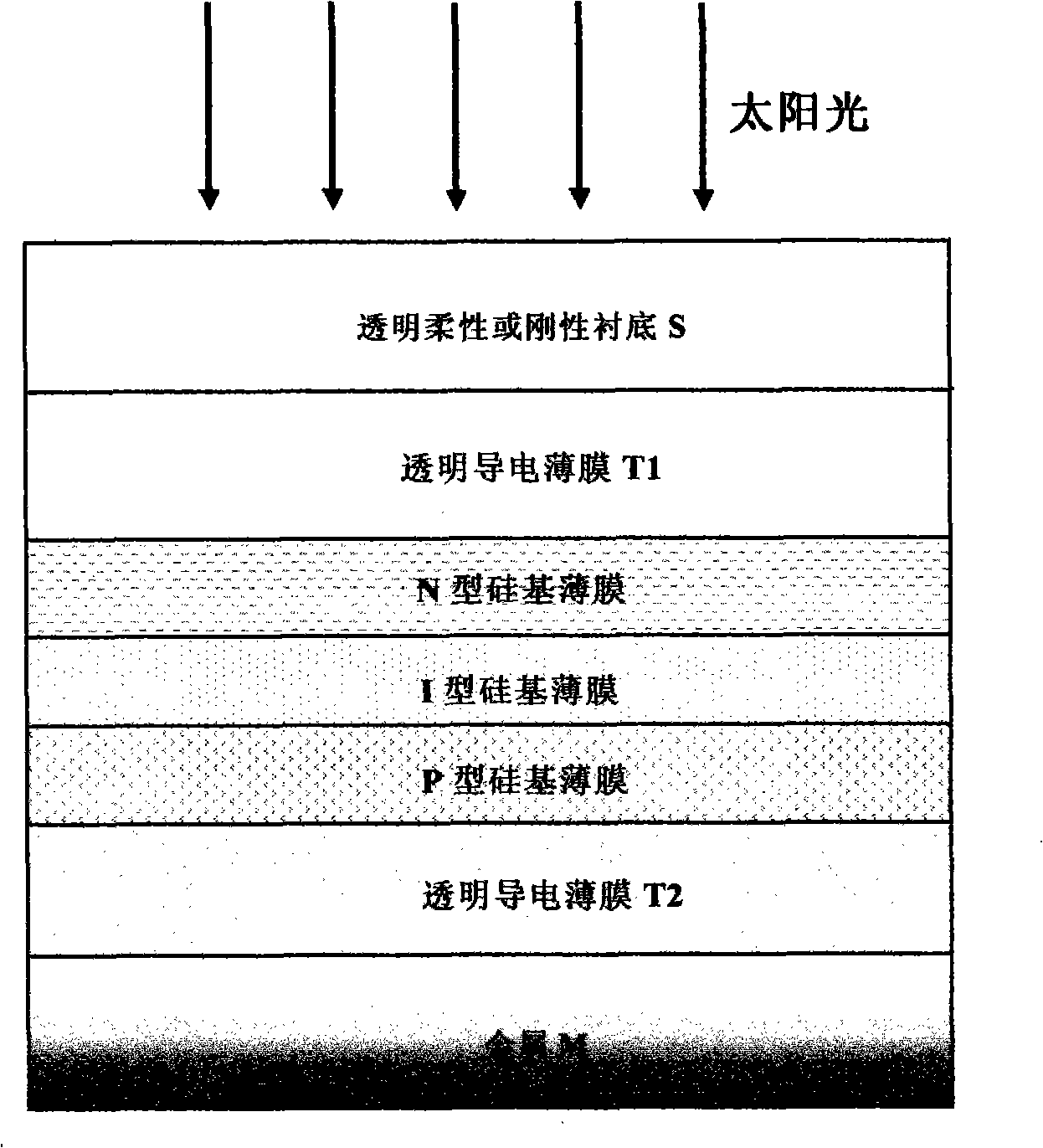

[0035] based on figure 1 with figure 2 The preparation of P / I / N type on a flexible or rigid substrate and the preparation of N / I / P type thin film solar cells on a transparent flexible or rigid substrate as shown, taking the PECVD method as an example, introduces the deposition of N-type microcrystals Silicon oxide (μc-SiO:H) functional material is used as the window material of the silicon-based thin film solar cell of the present invention, and the specific preparation process is as follows:

[0036] 1. For figure 1 , will have the sample of substrate S, metal M, transparent conductive film T1, boron-doped silicon-based film P, intrinsic silicon-based film I; or for figure 2 , put the sample with substrate S and transparent conductive film T1 into the PECVD deposition system, the background vacuum is higher than 10 -4 support;

[0037] 2. Control the reaction deposition parameters to deposit microcrystalline silicon oxide film on the above samples;

[0038] In step 2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com