LED element and luminous system and method for making LED element

A technology for light-emitting diodes and a manufacturing method, which is applied to electrical components, semiconductor devices, circuits, etc., can solve problems such as unfavorable luminous efficiency of light-emitting diode crystal grains, and achieve the effects of improving luminous efficiency and increasing luminous area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

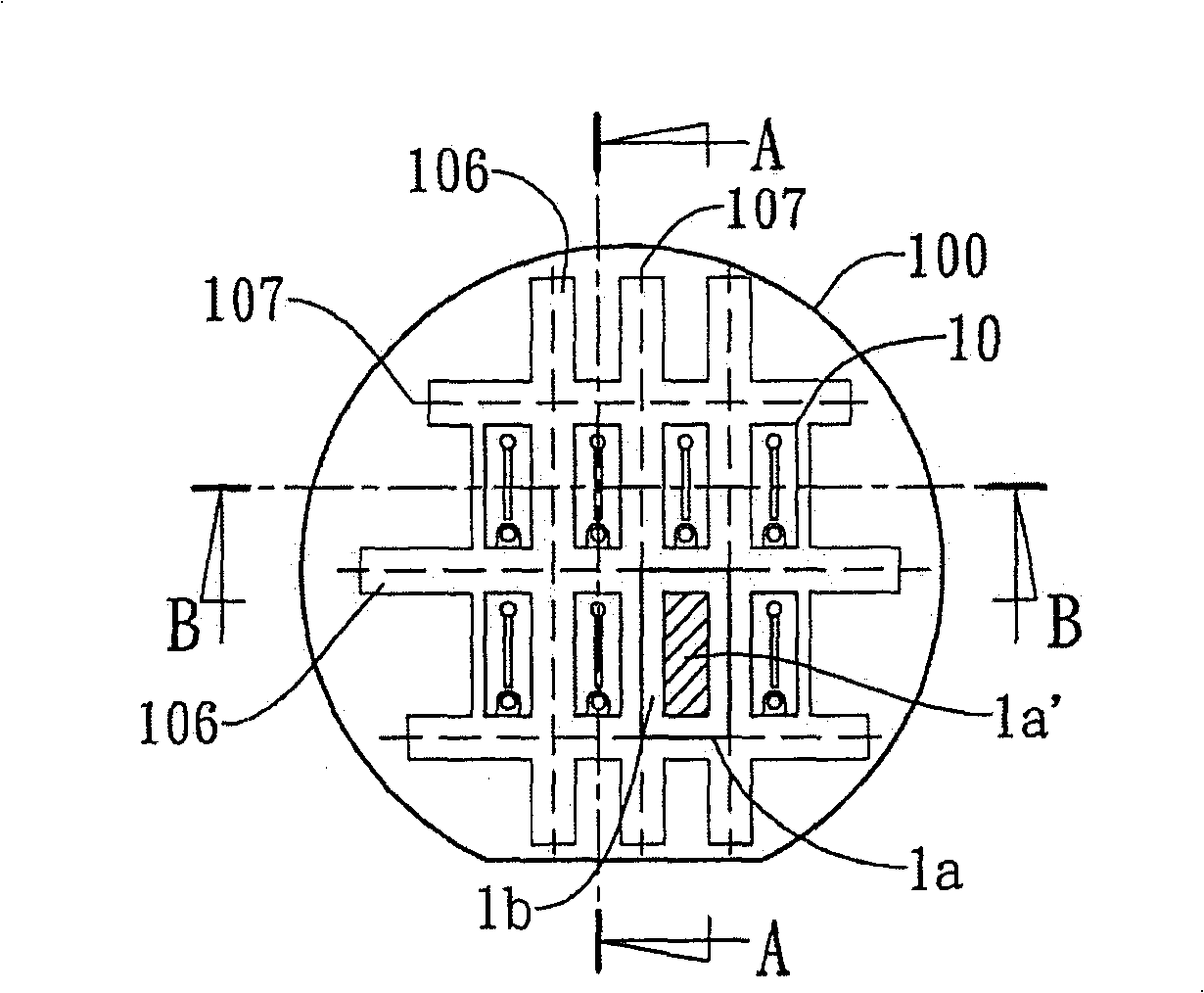

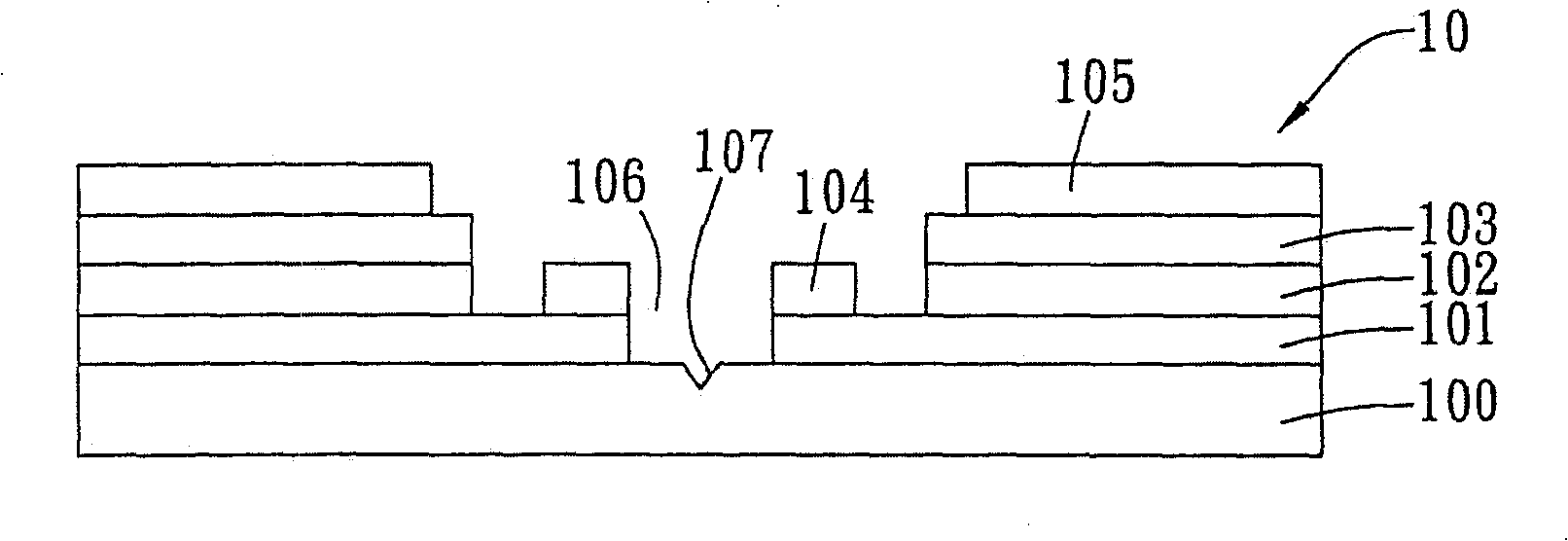

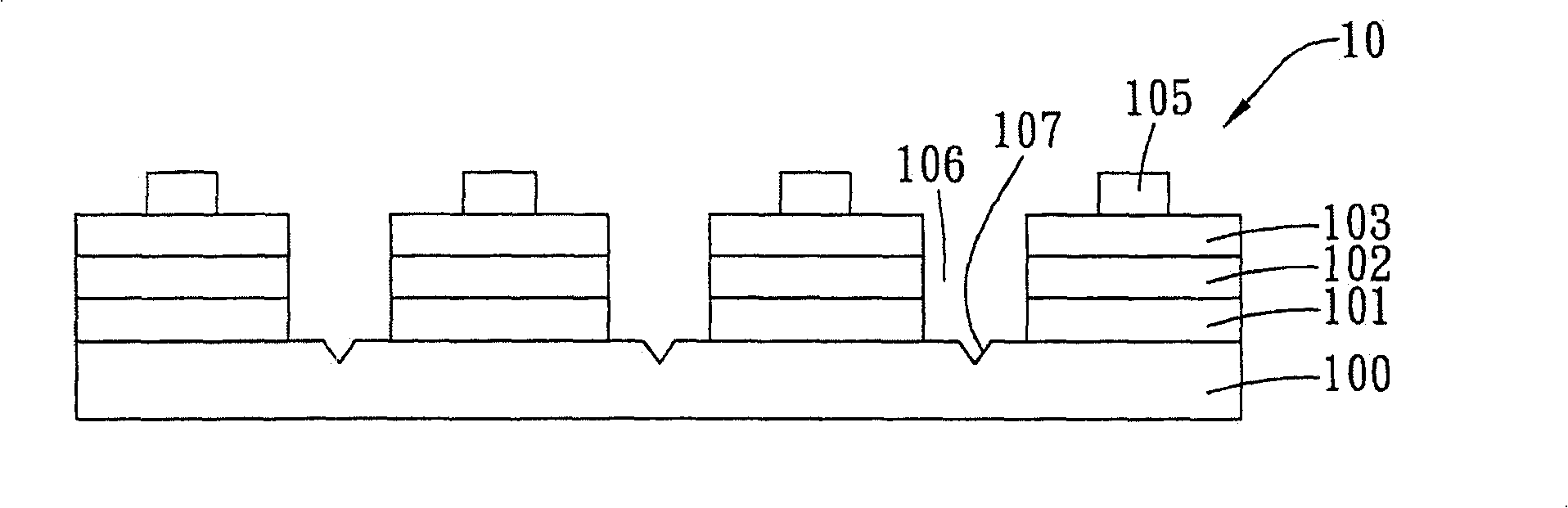

[0045] The present invention provides a self-aligned wafer dicing method (self-aligned wafersingulation method), which can separate LED chips on the wafer without pre-etching streets in at least one direction on the wafer. The method of the present invention can select at least one direction on the wafer without pre-etching the dicing line, for example, selecting the wafer at least along the crystal lattice direction that is most likely to break without pre-etching the dicing line, or on the two directions of the wafer without pre-etching the dicing line. eclipse cut. Since the wafer area is not occupied by the etching scribe along at least one direction, the wafer area occupied by each LED grain can be increased, thereby increasing its light-emitting area, so that the light-emitting efficiency of the LED element manufactured by the present invention is improved.

[0046] The light-emitting diode element and light-emitting system of the present invention and the method for man...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com