Method and device for recovering organic solvent from waste gases of printing industry

An organic solvent, adsorption recovery technology, applied in the field of environmental protection, can solve the problems of high energy consumption of electric heating, difficulty in direct discharge, high operating costs, etc., and achieve the effect of high recovery efficiency, convenient operation, and compensation of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

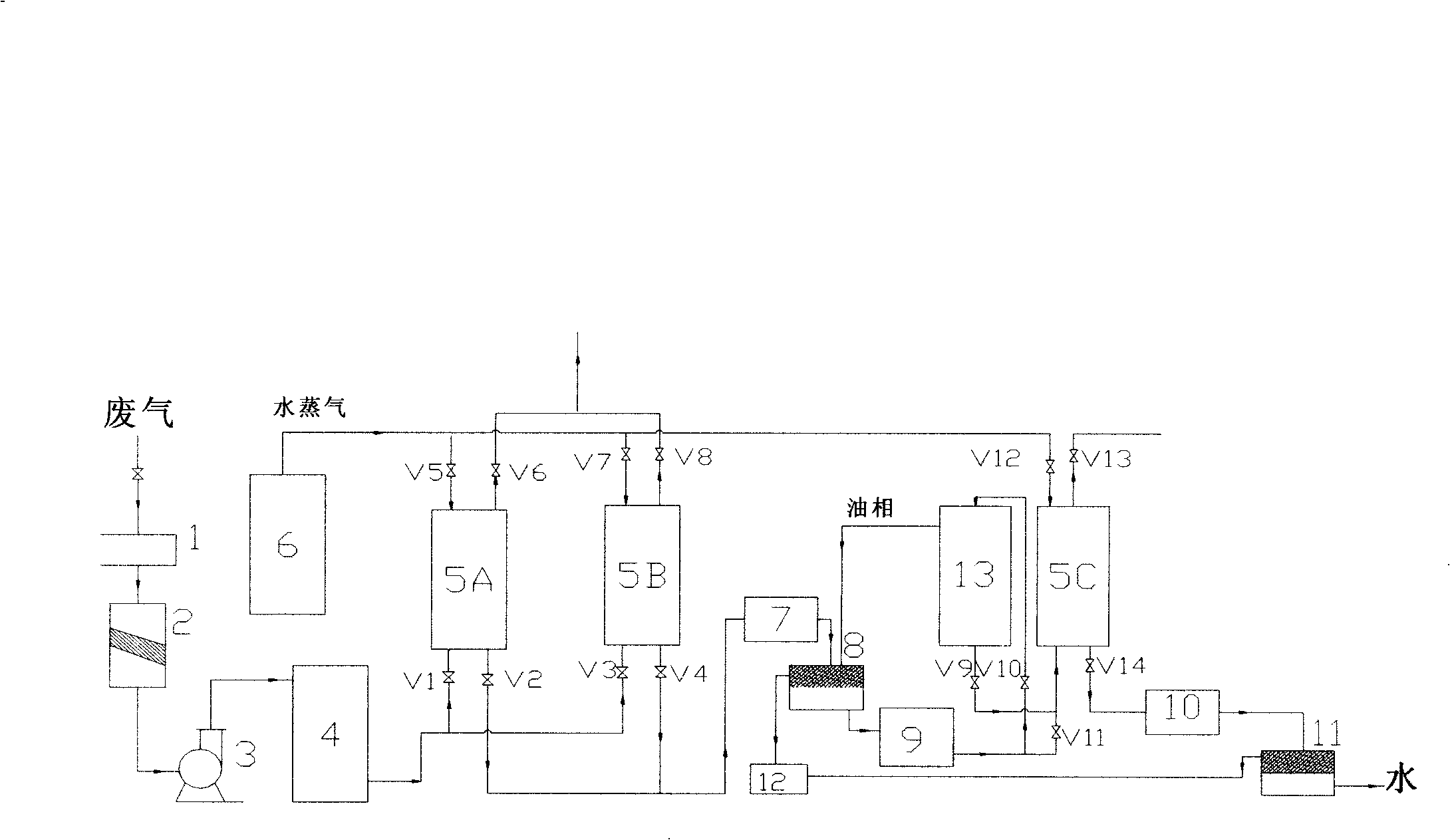

[0024]Purify and recycle the organic waste gas emitted by the printing factory. The main components of the waste gas are toluene, acetone, and isopropanol. The mass ratio between the three is 5:2:1. The exhaust volume of the plant is 10000m3 / h, and the concentration of the organic waste gas is 1000ppm, the organic waste gas from the printing workshop passes through the filter to remove the dust and particle impurities under the action of the fan, and enters the cooler through the flame arrester to cool down. The temperature reaches 35°C, and the cooled waste gas is passed into one of the adsorbers Adsorption, when the outlet concentration of the adsorbate reaches 30ppm, the adsorber stops adsorption, and the waste gas is transferred to the second adsorber for adsorption; the adsorption is near the saturated adsorber, which uses water vapor heating for desorption and desorption, and the mass ratio of water vapor to solvent is 3:1, the desorbed mixed vapor is condensed by one of ...

Embodiment 2

[0026] Purify and recycle the organic waste gas emitted by the printing factory. The main components of the waste gas are toluene, acetone, and isopropanol. The mass ratio between the three is 6:3:2. The exhaust volume of the plant is 10000m3 / h, and the concentration of the organic waste gas is 1000ppm, the organic waste gas from the printing workshop passes through the filter to remove the dust and particle impurities under the action of the fan, and enters the cooler through the flame arrester to cool down. The temperature reaches 30°C, and the cooled waste gas is passed into one of the adsorbers Adsorption, when the outlet concentration of the adsorbate reaches 32ppm, the adsorber stops adsorption, and the exhaust gas is transferred to the second adsorber for adsorption; the adsorption is near the saturated adsorber, which uses water vapor heating for desorption and desorption, and the mass ratio of water vapor to solvent is 5:1, the desorbed mixed vapor is condensed by one ...

Embodiment 3

[0028] Purify and recycle the organic waste gas emitted by the printing factory. The main components of the waste gas are toluene, acetone, and isopropanol. The mass ratio between the three is 5:2:1. The exhaust volume of the plant is 10000m3 / h, and the concentration of the organic waste gas is 1000ppm, the organic waste gas from the printing workshop passes through the filter to remove the dust and particle impurities under the action of the fan, and enters the cooler through the flame arrester to cool down. The temperature reaches 38°C, and the cooled waste gas is passed into one of the adsorbers Adsorption, when the outlet concentration of the adsorbate reaches 28ppm, this adsorber stops adsorption, and the waste gas is transferred to the second adsorber for adsorption; the adsorption is near the saturated adsorber, which uses water vapor heating for desorption and desorption, and the mass ratio of water vapor to solvent is 4:1, the desorbed mixed vapor is condensed by one o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com