Horizontal radiation type electrolysis method and device

A technology of electrolysis device and electrolysis method, which is applied in the direction of electrolysis process, electrolysis components, chemical instruments and methods, etc. It can solve the problems of calcium accumulation, space occupation, and inability to adjust the electrolytic tank, and achieve the solution of accelerating calcium accumulation, reducing costs, and shunting easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

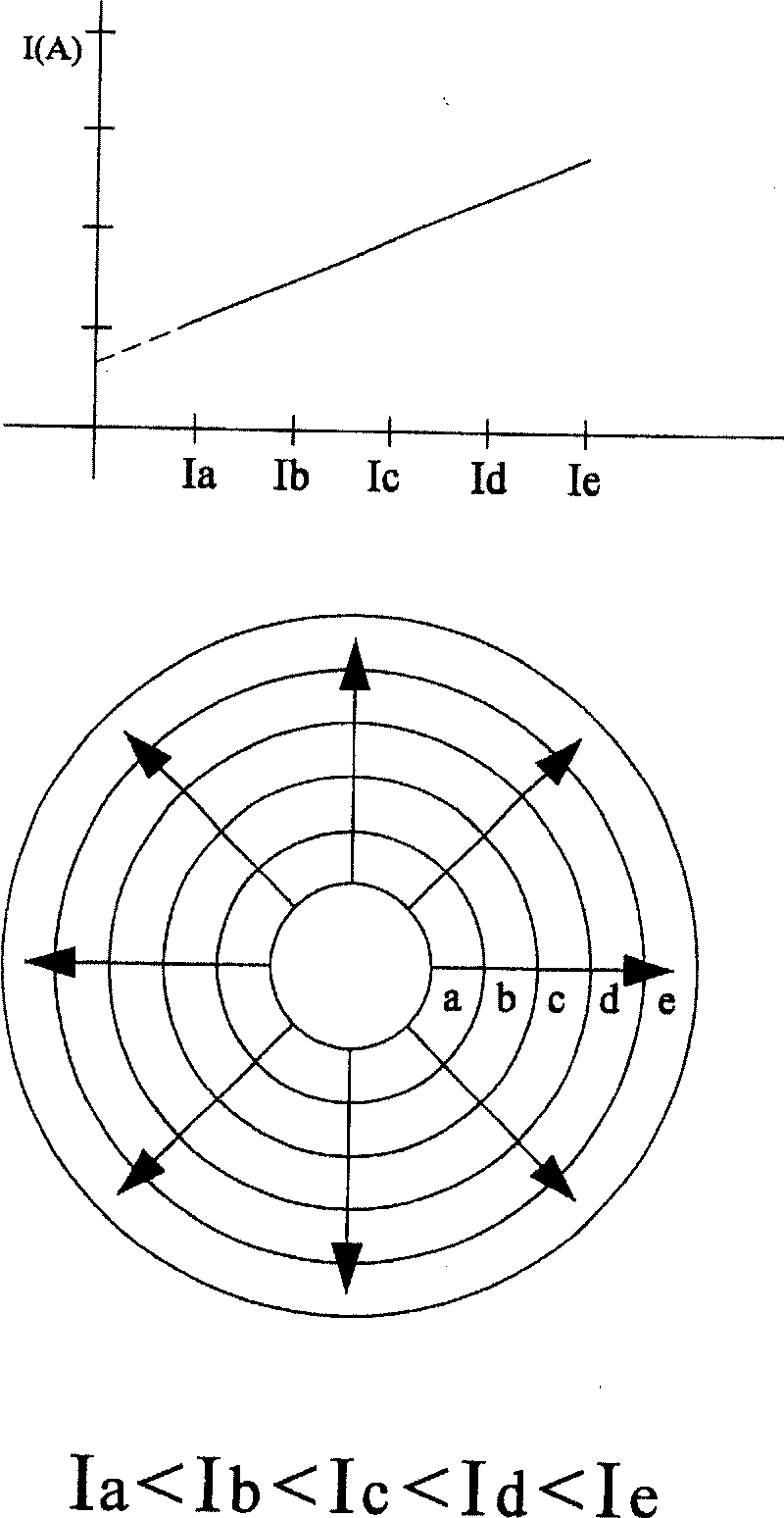

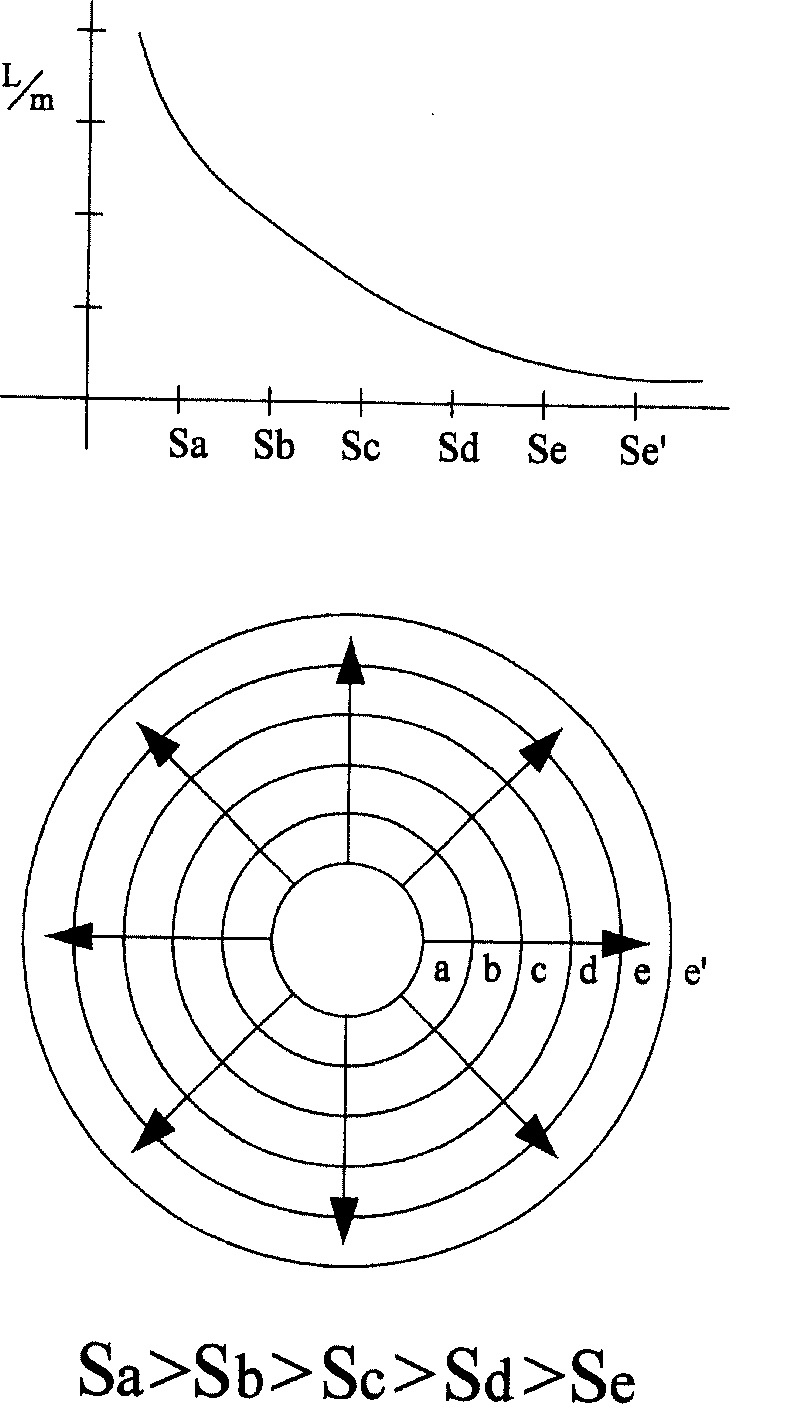

[0071] A horizontal radiation electrolysis method is characterized in that the raw water is introduced from the center of the electrode plate and radiated out horizontally outward, so that the flow rate of the incoming water can be slowed down during electrolysis and the best electrolysis efficiency can be obtained.

[0072] According to the above-mentioned horizontal radiation electrolysis method of the present invention, the produced horizontal radiation electrolysis device includes at least the following seven embodiments:

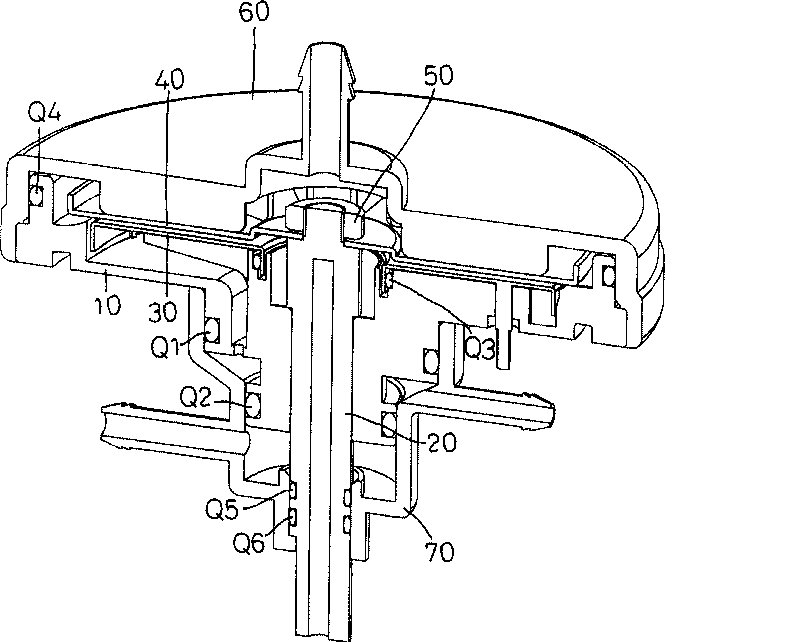

[0073] Regarding the first embodiment of the present invention, please refer to image 3 , 4 , 5, image 3 , 4 It is a three-dimensional combined cross-sectional view and a three-dimensional exploded schematic view of the first embodiment of the present invention. Figure 5 It is a schematic diagram of the cross-sectional combination of the first embodiment of the present invention. The electrolysis device includes a base body 10 , a conductor 20 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com